Steel bone pre-set combination walling unit, steel bone wall and construction method thereof

A wall and steel reinforced technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of prolonged completion period, unqualified walls, rework, etc., and achieve comprehensive cost reduction, project quality improvement, and elimination of construction pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

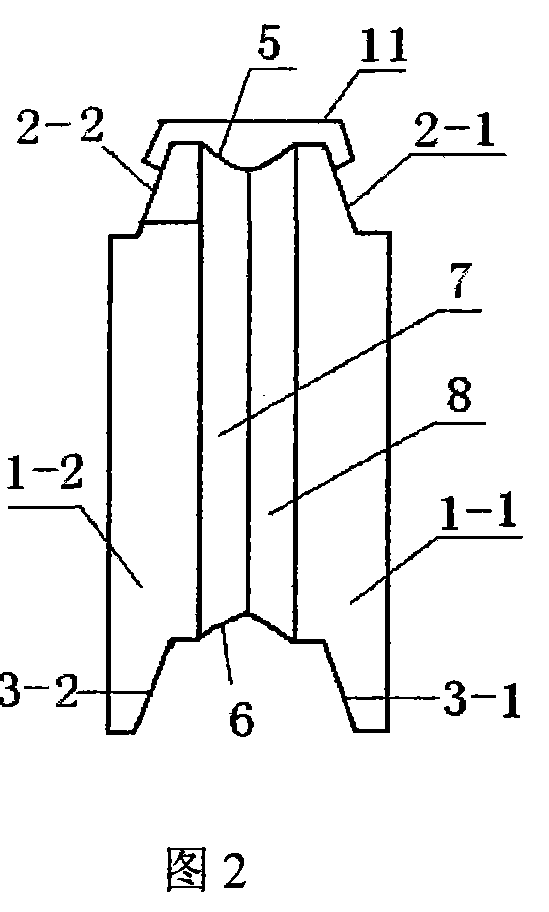

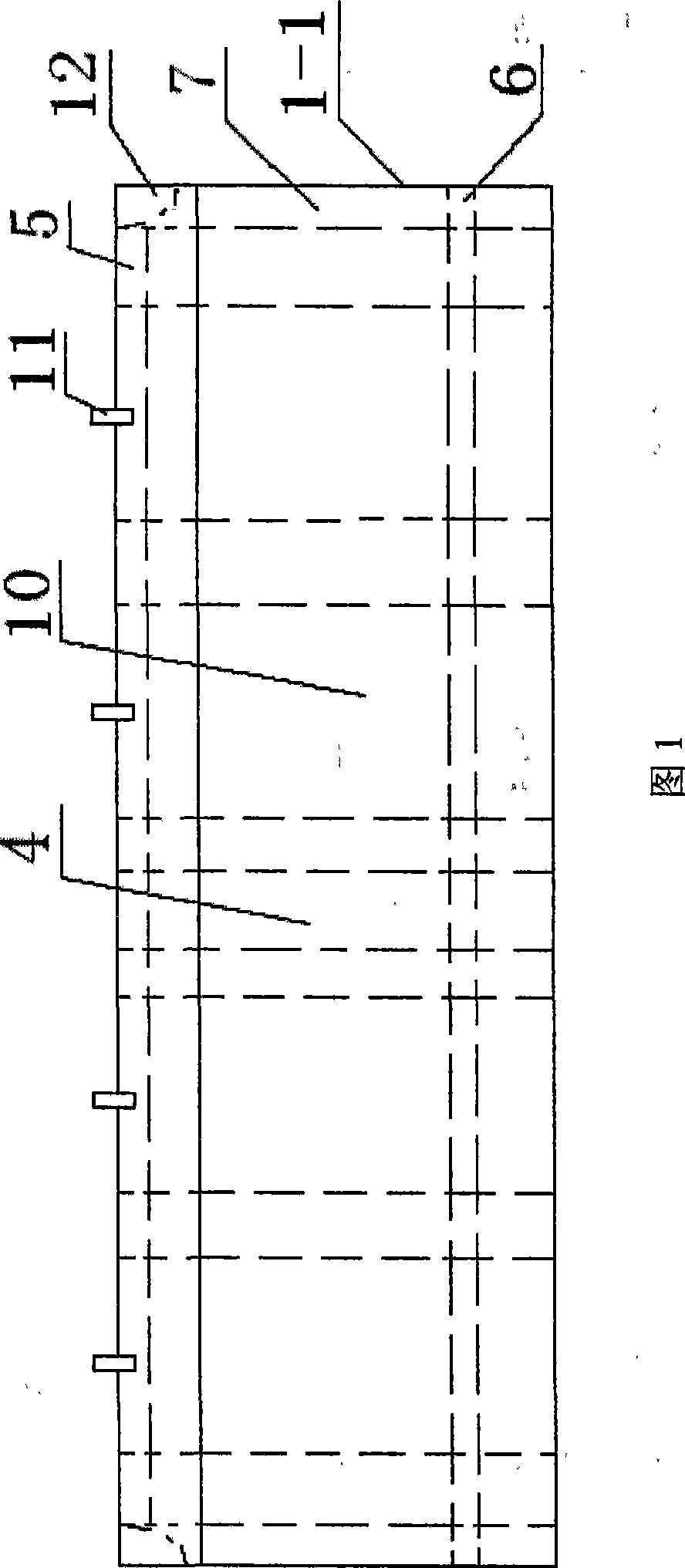

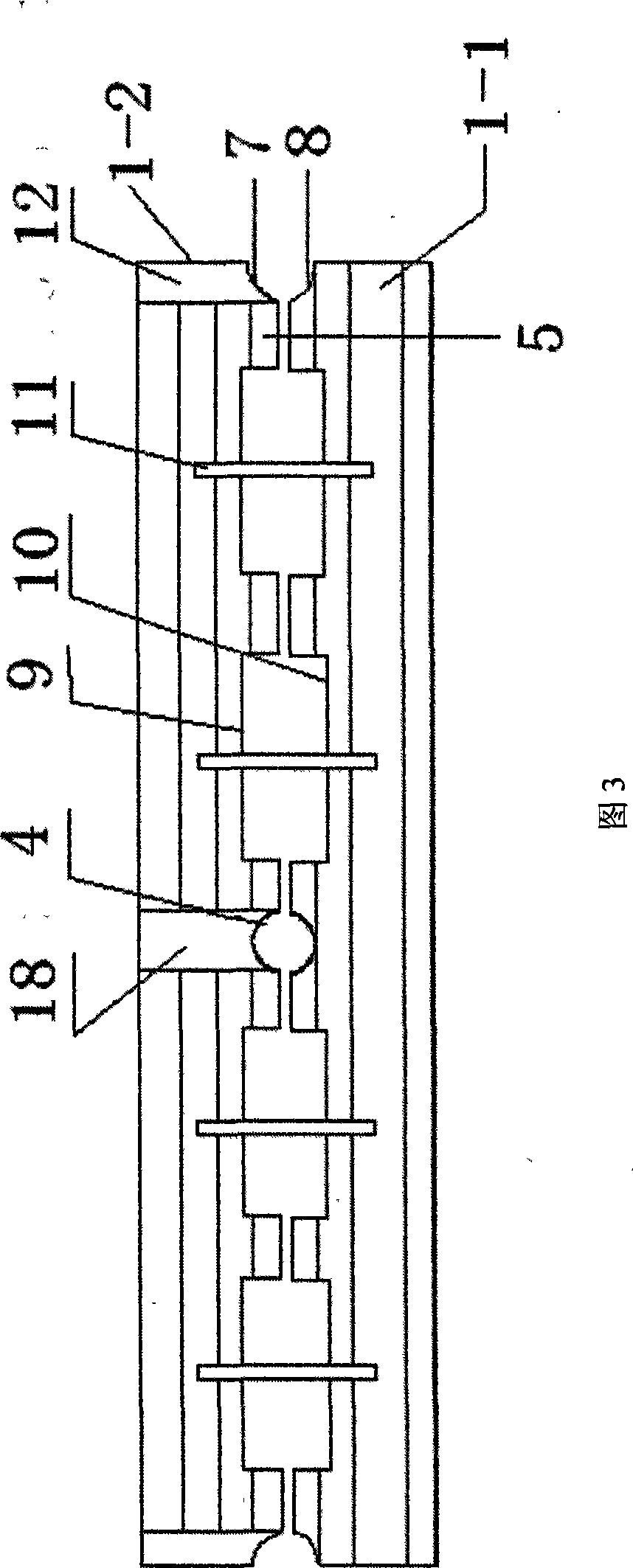

[0035] The reference of the preset steel-reinforced composite wall block in this embodiment Figure 1-5 , including two independently separated symmetrical blocks 1-1, 1-2, which are integrated when used, and the upper end faces of the symmetrical blocks 1-1, 1-2 are provided with The protrusions 2-1, 2-2 forming the convex connection end, the lower end faces of the symmetrical blocks 1-1, 1-2 are provided with grooves 3-1, 3-2 forming the concave connection end, which are used together The centers of the symmetrical blocks 1-1 and 1-2 are respectively provided with grooves 4 forming longitudinal reinforcement holes along the interval lines in the horizontal direction, constituting a fixed positioning modulus. No matter rectangular or square blocks, when using the same specification to build walls, no matter whether you use straight joints or pressure joints, the joints can be penetrated through the ribs up and down, that is, Achieving reinforcement at block joints;

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com