A method for quickly constructing horizontal and super large salt cavern solution cavity storage

A super-large salt, flat-horizontal technology, applied in the direction of earth drilling, mining equipment, underground chambers, etc., can solve the problem of small cavity size, slow speed, well construction of inclined wells and the inability to fully utilize the cavity in the horizontal section, etc. problems, to achieve the effect of improving the recovery rate of rock salt and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) 1# and 2# vertical wells are arranged in the rock salt mining area, which are (Z1, Z2) respectively, the completion depths are 1745m and 1780m, and the well spacing is 200m.

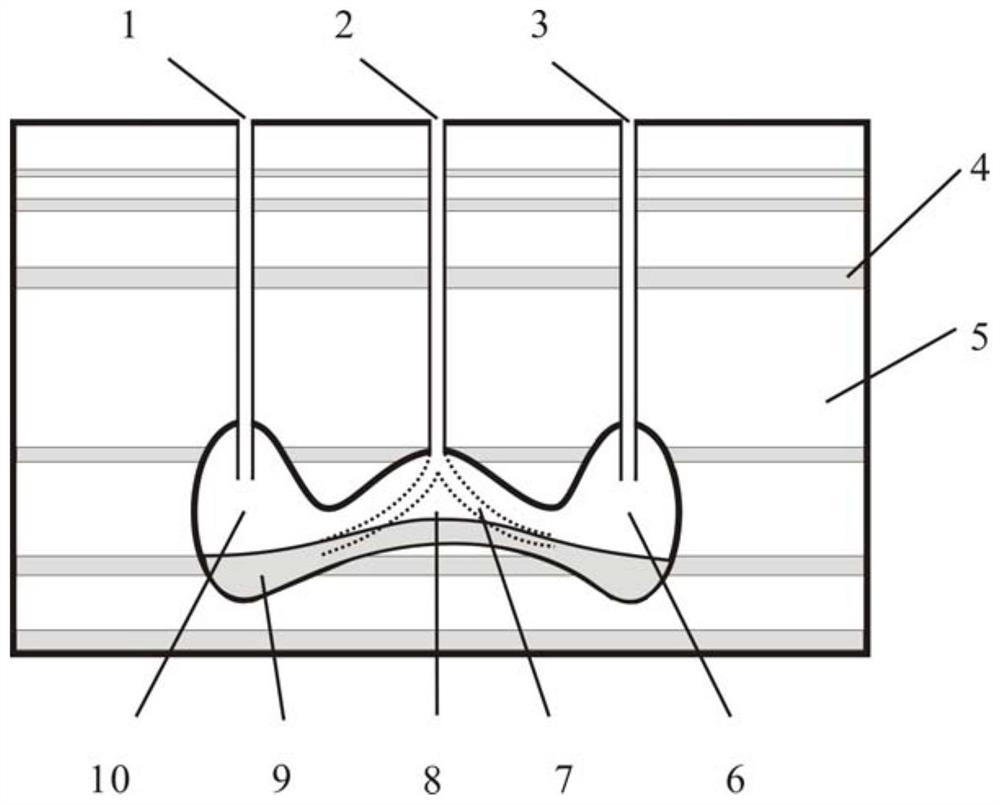

[0059] (2) Deploy 3# inclined well (Z3) between the two vertical wells and connect with Z1 and Z2 respectively through directional docking. The build-up point of Well Z3 is 1550m, and the build-up rate is 9.5° / 30m; the vertical depth of the docking point on the Z1 side is 1743m, and the well inclination is 61.11°; the vertical depth of the Z2 docking point is 1776m, the well deviation is 72.83°, and Z1 and Z2 ( image 3 ). The three wells are connected to alternate combined injection and row construction. The construction process adopts the method of "two injections and one row", and the construction period lasts for 3 months. In the first month, wells Z1 and Z2 were injected with water, and the water injection flow of both wells was 60m 3 / h, Z3 well drains brine; in the second month, Z1 an...

Embodiment 2

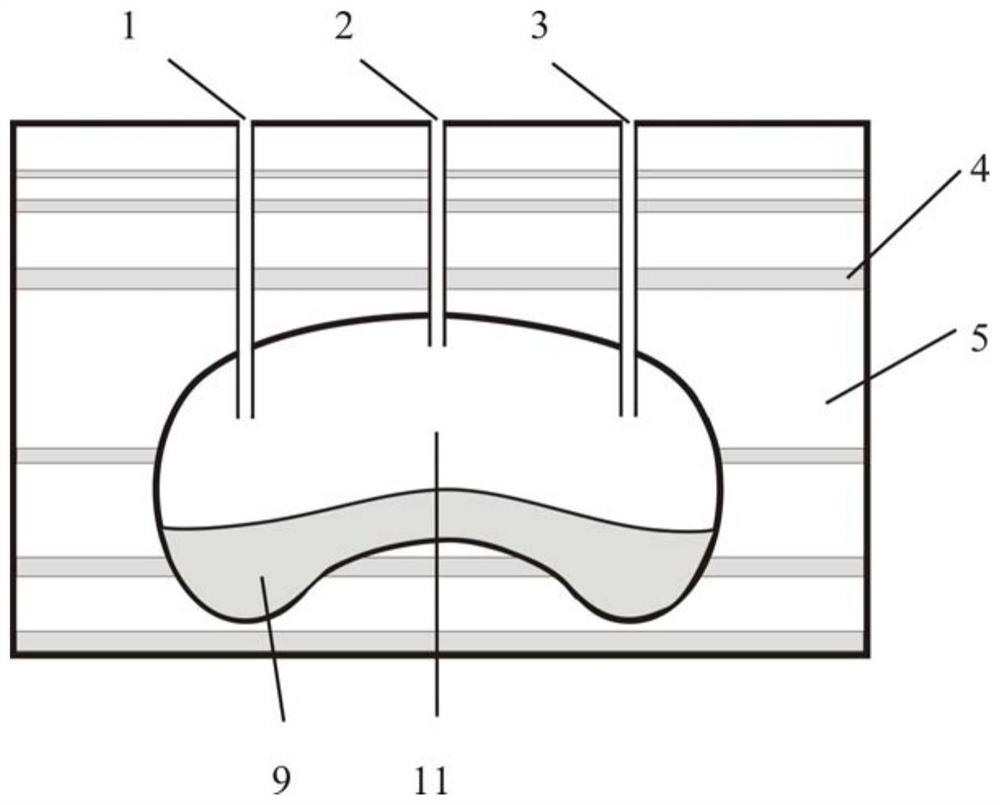

[0067] (1) Two vertical wells 1# and 2# were selected for 11 years of production in the rock salt mining area, which are X1 and X2 respectively. The completion depths of the two vertical wells are 1370m and 1285m respectively, and the well spacing is 160m. Wells X1 and X2 have been naturally dissolved.

[0068] (2) Since the cavities of wells X1 and X2 have been dissolved, the 3# vertical well (X3) will be constructed between the two vertical wells in the later stage. Well X3 will be directly drilled into the dissolved cavities of X1 and X2, and the three wells will be connected with X1 and X2 ( Figure 4 ).

[0069] (3) According to the cavity measurement results, the X1 and X2 cavities are dissolved up to 1220m and 1215m, and the effective cavity volumes are about 26×10 4 m 3 , 19×10 4 m 3 . The top of the corresponding cavity in Well X3 dissolves to 1263m. Compared with the dissolution of X1 and X2, well X3 lags behind. Take X3 water injection (water injection speed i...

Embodiment 3

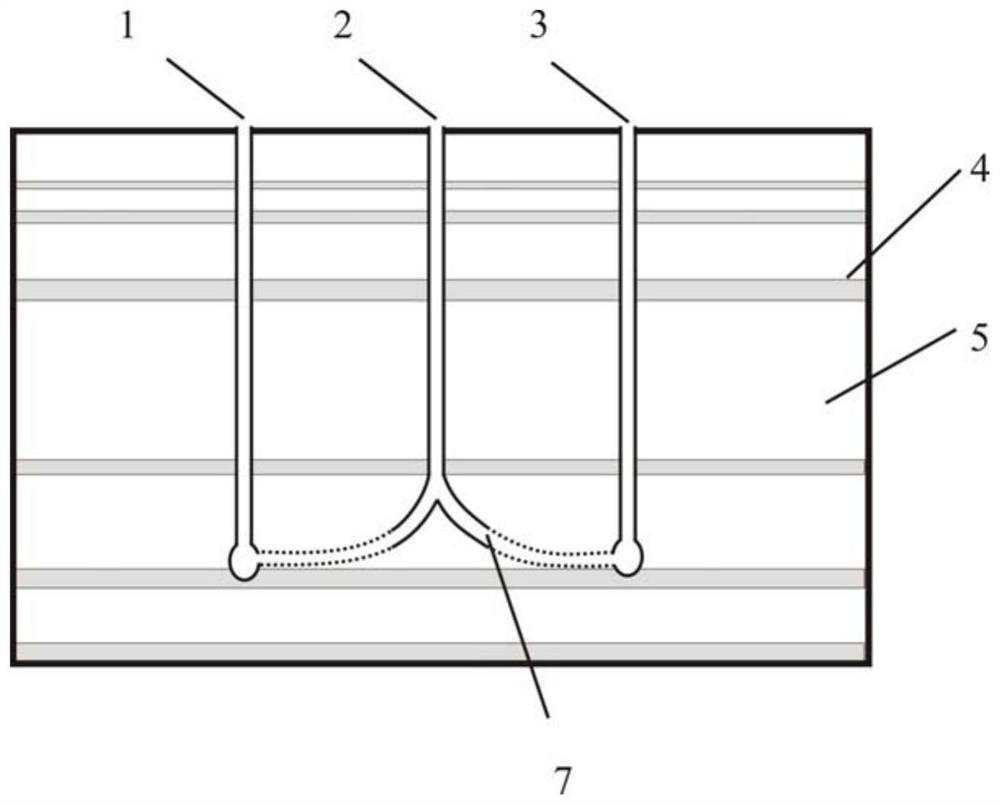

[0074] (1) Select a group of paired wells in the rock salt mining area. Well 1# is a directional well and Well 2# is a vertical well, respectively J1 and J2. The completion depths are 1450m and 1385m respectively, the well spacing is 180m, and the cumulative thickness of the rock salt layer is up to 600m. Among them, J1 and J2 are a pair of wells that have been produced for 4 years.

[0075] (2) Since there is already a horizontal section cavity (or channel) between wells J1 and J2, a 3# vertical well (J3) will be constructed between the two wells in the later stage, and Well J3 will be drilled directly into the horizontal section cavity (or channel), Three wells connected with J1 and J2 ( Figure 5 ).

[0076] (3) According to the cavity measurement results, the tops of the J1 and J2 cavities were dissolved to 1350m and 1335m, and the measured cavity volumes were 18×10 4 m 3 , 5×10 4 m 3 . The upper dissolution of the corresponding cavity of Well J3 is 1410m, which lag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com