Coating pretreatment process for discoloration-resistant paint

A technology of discoloration resistance and pretreatment, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc. Paint and coating work efficiency and other issues, to improve the effect of discoloration resistance, shorten the residence time, and ensure the uniformity of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

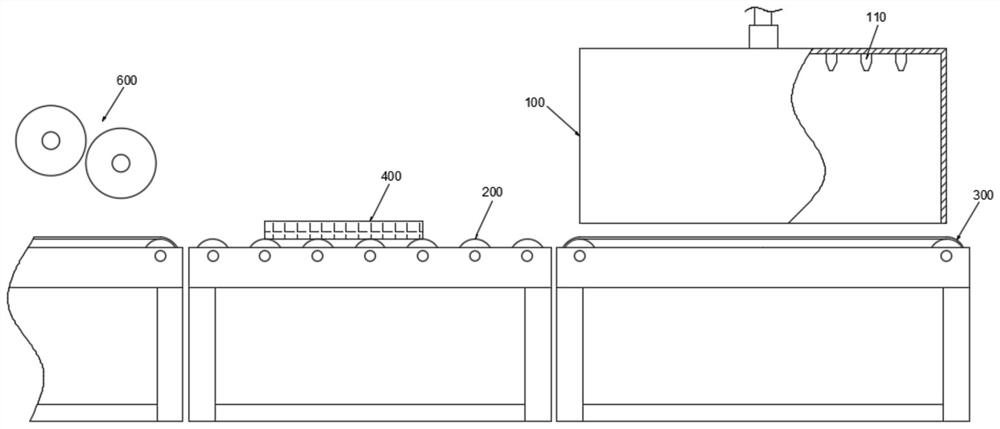

[0031] Embodiment 1: a kind of discoloration-resistant paint coating pretreatment process, the treatment process is implemented between the paint finish sanding process and the water-based primer coating process, and sequentially includes the coating step of the water-based discoloration-resistant paint, and the water-based discoloration-resistant paint. Paint curing step. Among them, the water-based discoloration-resistant paints used are commercially available, such as German Jenver anti-yellowing primers or anti-red primers. In this example, the disc bean is treated, so the German kenfor yellow-resistant primer is selected. If the treatment is for Jatoba, the German kenfor-resistant red primer can be selected.

[0032] By means of the above method, curing the water-based discoloration-resistant paint through a high-temperature thermal curing process can effectively shorten the curing time of the water-based discoloration-resistant paint and improve the work efficiency of th...

Embodiment 2

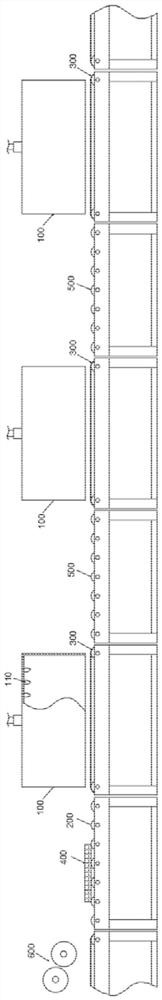

[0039] Example 2: The difference between Example 2 and Example 1 is that the curing step of the waterborne discoloration-resistant paint includes multiple thermal curing stages and a buffer stage connecting adjacent thermal curing stages. For example, after finishing the coating of the water-based discoloration-resistant paint, the painted workpiece 400 passes through the leveling section 200, and then sequentially enters the first heat curing stage, the first buffer stage, the second heat curing stage, and the second heat curing stage. The second buffer stage and the third heat curing stage are used to complete the curing step of the water-based discoloration-resistant paint. By dividing the curing step of the water-based discoloration-resistant paint into multiple thermal curing stages, the time during which the painted workpiece 400 is in a single thermal curing stage can be shortened, so as to reduce the influence of high temperature on the moisture content of the painted w...

Embodiment 3

[0049] The difference between Example 3 and Example 1 is that the coating step of the waterborne discoloration-resistant paint, the leveling step of the waterborne discoloration-resistant paint, and the curing step of the waterborne discoloration-resistant paint are repeated twice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com