Lifting structure, single wafer cleaning mechanism, method and equipment

A technology of lifting structure and cleaning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In order to improve the technical problem of poor lift synchronization in the prior art, a lift structure 13 is provided in this embodiment.

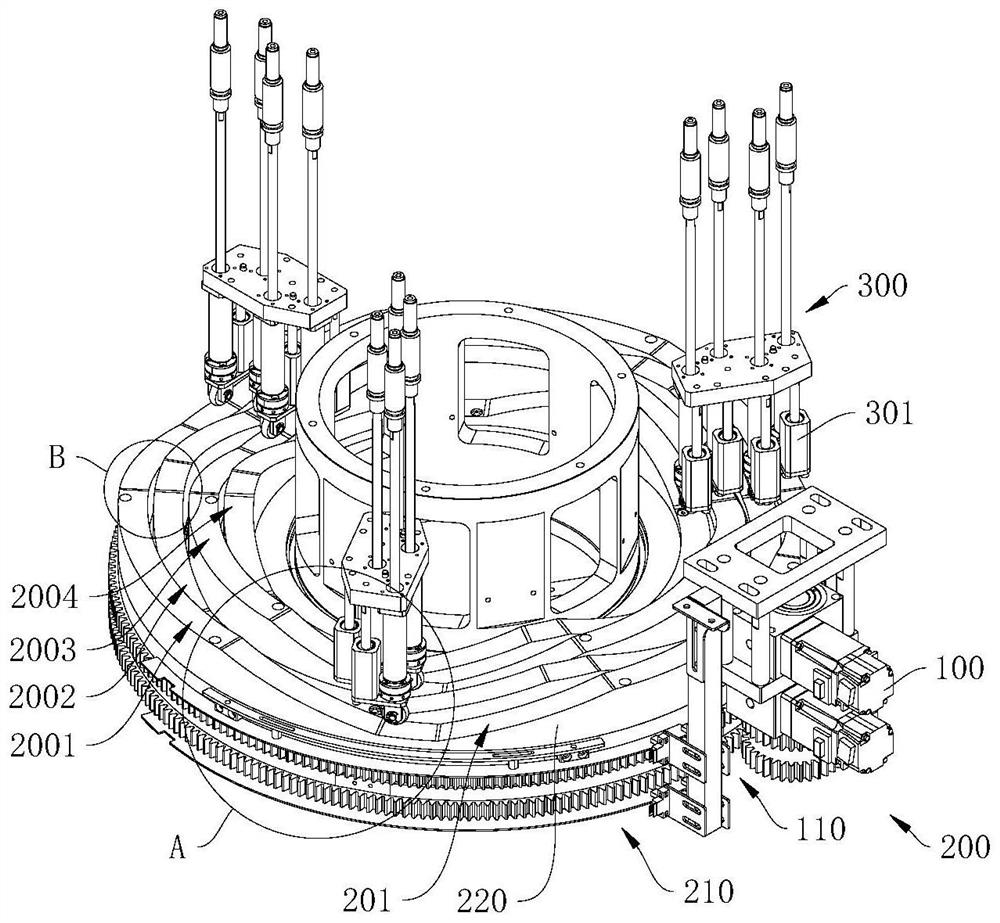

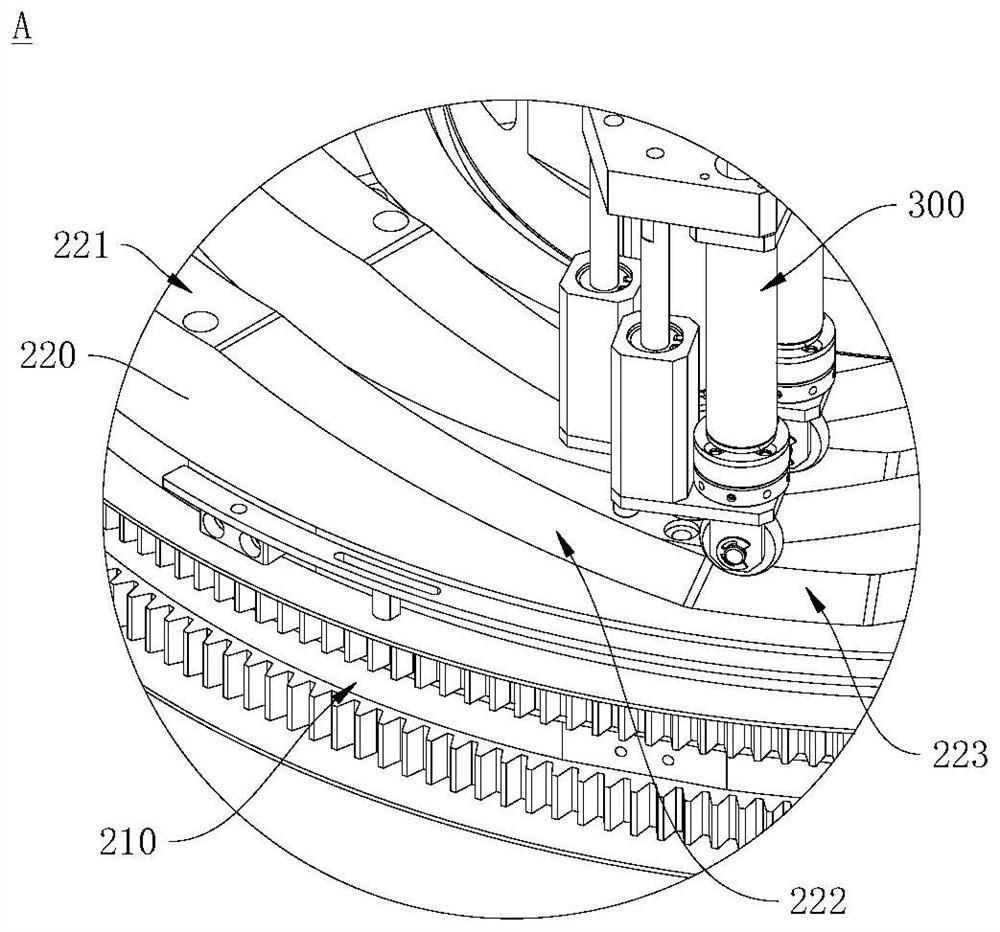

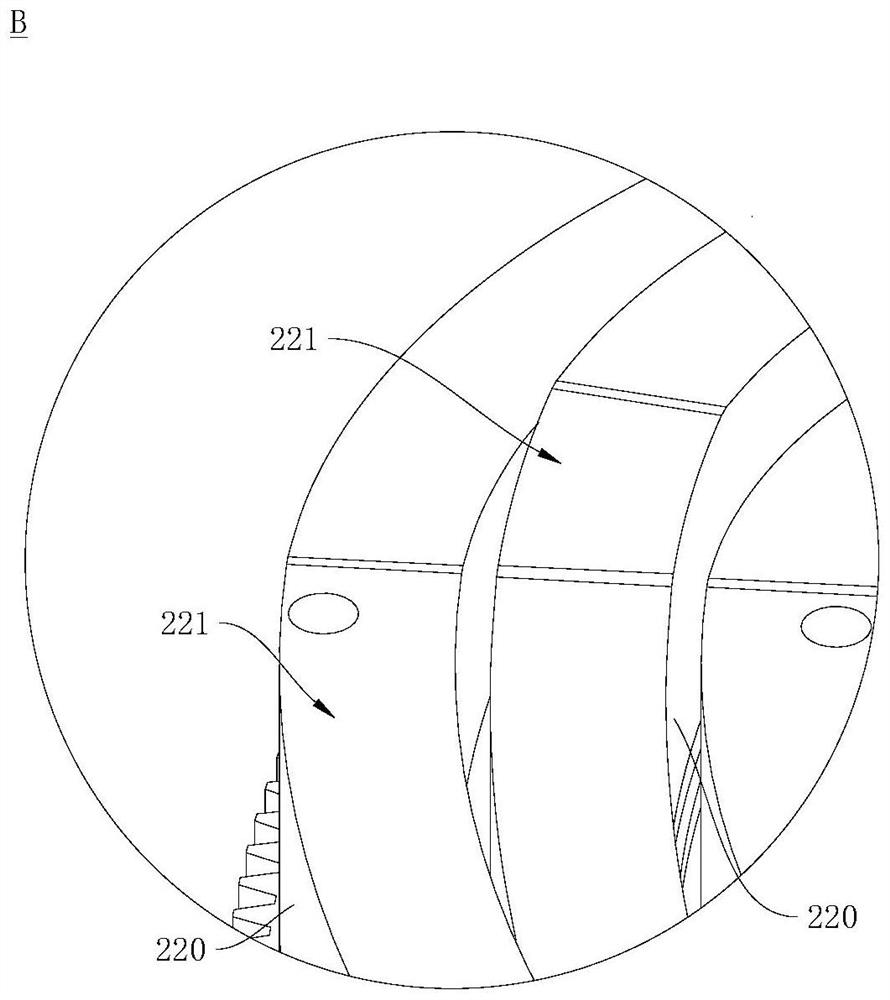

[0055] Among them, see figure 1 , figure 1 A schematic structural diagram of the lifting structure 13 provided in the embodiment of the present application is shown. The lift structure 13 includes a drive assembly 200 and at least one lift assembly 300 . The driving assembly 200 includes a driving part 210 and an abutting body 220 , and the abutting body 220 is connected with the driving part 210 . The top of the abutting body 220 has an abutting surface 201 , and the abutting surface 201 is undulating in a predetermined direction. In other words, the heights of the abutting body 220 at different positions relative to the driving part 210 vary. One end of the lift assembly 300 abuts against the abutment surface 201 , and when the driving part 210 drives the abutment body 220 to move in a predetermined direction, the lift asse...

Embodiment 2

[0091] see Figure 5 , Figure 5 A schematic structural diagram of the single-wafer cleaning mechanism 10 provided in this embodiment is shown. In this embodiment, a single-wafer cleaning mechanism 10 is provided. The single-wafer cleaning mechanism 10 is used to clean a single wafer to remove residues, fine dust, dirt, etc. on the single wafer, so as to ensure that the single wafer is cleaned. Wafers are of high quality. In the process of cleaning the single wafer, the single wafer cleaning mechanism 10 will spray a variety of chemicals on the single wafer to ensure that various residues on the single wafer can be effectively cleaned. Based on this, in order to prevent cross-contamination between multiple agents, in the process of cleaning a single wafer with each agent, the products generated after cleaning a single wafer with each agent need to be collected separately.

[0092] The single-wafer cleaning mechanism 10 has multiple covers 12, the multiple covers 12 are cove...

Embodiment 3

[0111] Based on the single-wafer cleaning mechanism 10 provided in the second embodiment, a single-wafer cleaning method is provided in this embodiment, and the method can be applied to any single-wafer cleaning mechanism 10 provided in the second embodiment. The wafer is cleaned to improve the technical problem of poor lift synchronization in the prior art.

[0112] Among them, in order to facilitate the execution of the single-wafer cleaning method, in this embodiment, the single-wafer cleaning mechanism 10 may further include a control device, the driving part 210 is electrically connected to the control device, and the control device can control the operation of the driving part 210 to control the Lifting and lowering of the plurality of covers 12 . The cleaning mechanism 15 is electrically connected to the control device, the control device can control the cleaning mechanism 15 to clean the wafer, and the cleaning mechanism 15 can also feed back a signal indicating that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com