H-shaped copper pipe drawing die assembly

A drawing die and pipe die technology, applied in the field of H-shaped copper pipe drawing die assemblies, can solve the problems of difficulty in making special-shaped pipes, inability to draw small copper pipes, strength of small pipe fittings, etc. The effect of smooth drawing and precise forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

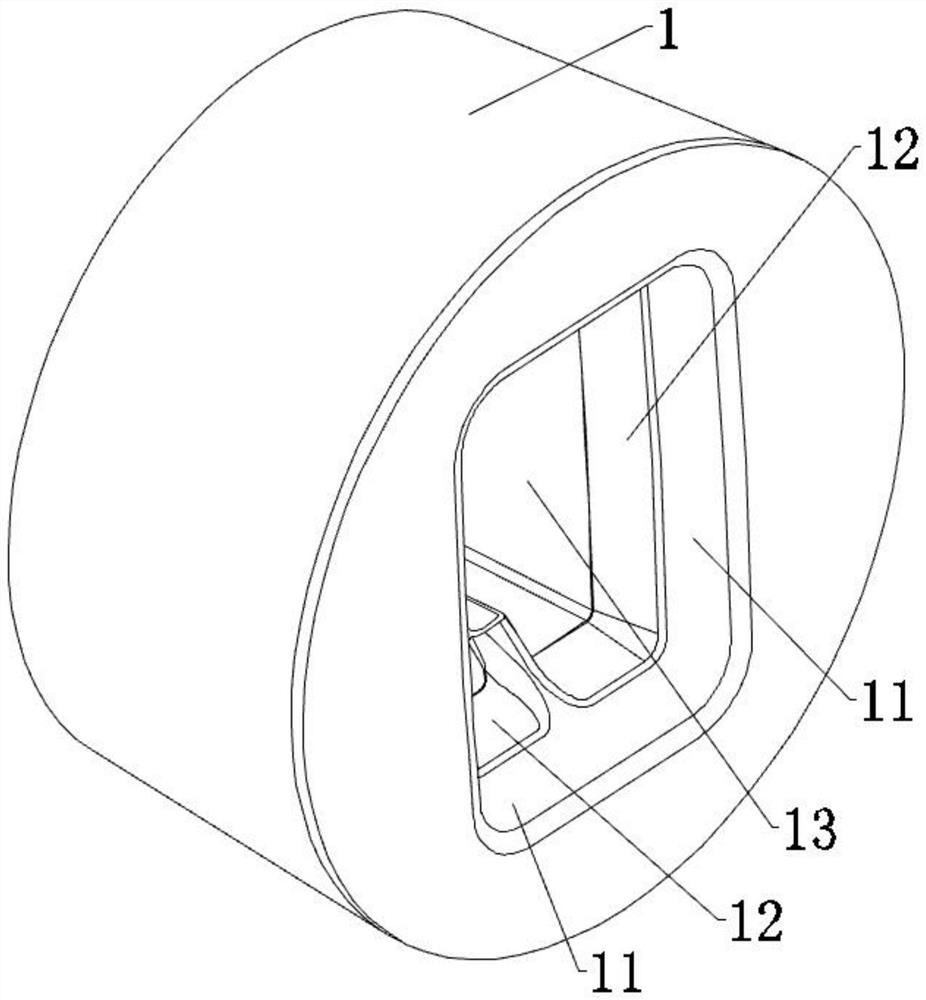

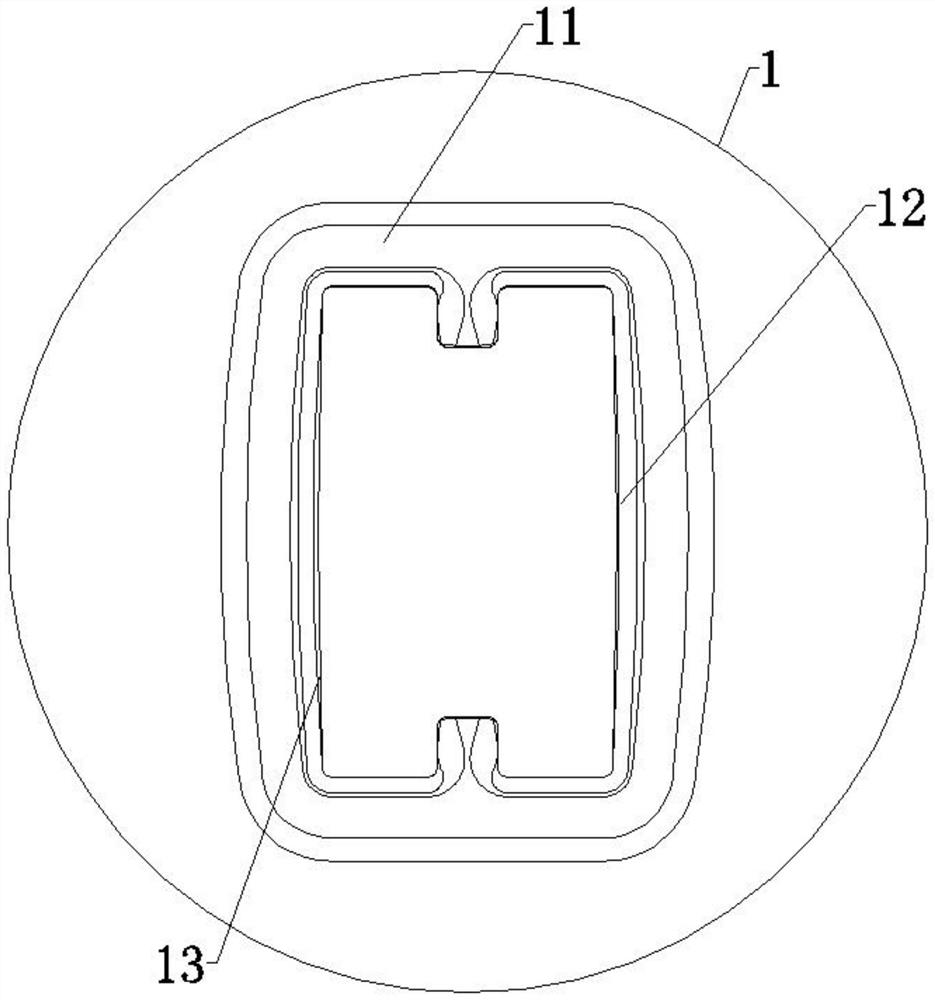

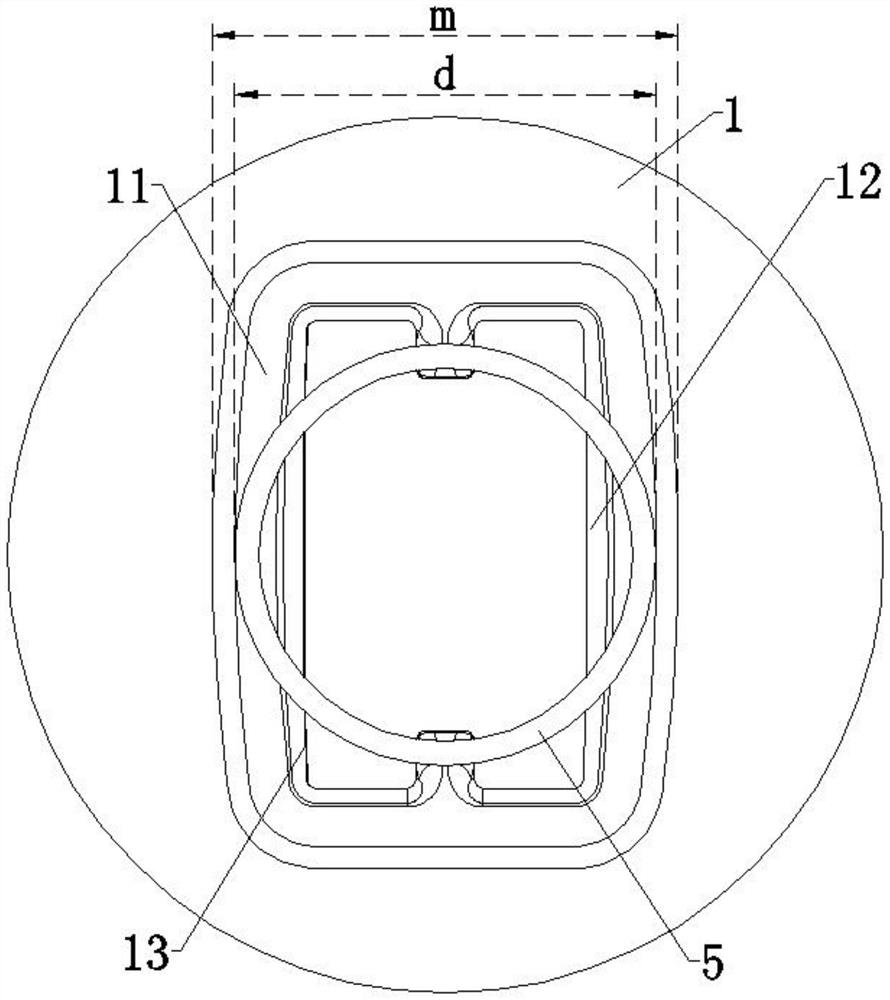

[0037] see Figures 1 to 7 As shown, the present invention provides a technical solution: an H-shaped copper tube drawing die assembly, comprising:

[0038] Two sets of drawing die assemblies, one set of drawing die assemblies is assembled by the first tube drawing die 1 and the large lining core 3, and the other set of drawing die assemblies is the second tube drawing die 2 and the small lining core 32 are assembled together;

[0039] The first tube-drawing die 1 is a tube-drawing concave die with an H-shaped die hole in the middle, and the die hole penetrates the left and right sides of the first tube-drawing die 1;

[0040] The second tube-drawing die 2 is also a tube-drawing concave die with an H-shaped die hole in the middle, and the die hole penetrates the left and right sides of the second tube-drawing die 1;

[0041] The shape and size of the inner wall of the female die of the second tube-drawing die 2 is the same as the preset external shape and size of the cross-se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com