Hydraulic forging device for forging metal device

A metal device and hydraulic technology, applied in forging/pressing/hammer devices, driving devices of forging presses, and forging presses, etc., can solve the problems of not being able to fit the workpiece perfectly, hidden dangers, and ineffective limit forgings, etc. To achieve the effect of facilitating loading and unloading, reducing safety hazards and increasing usage scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

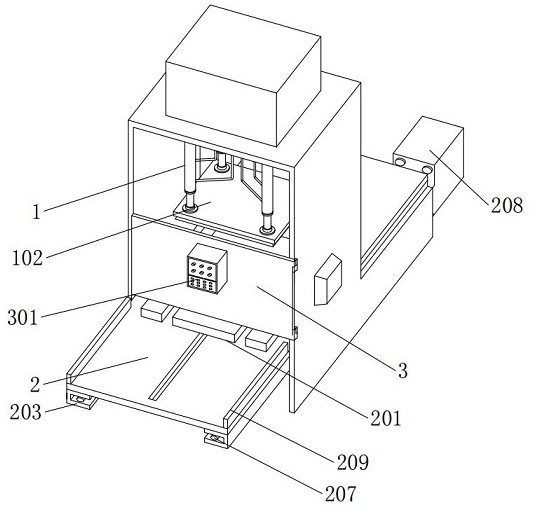

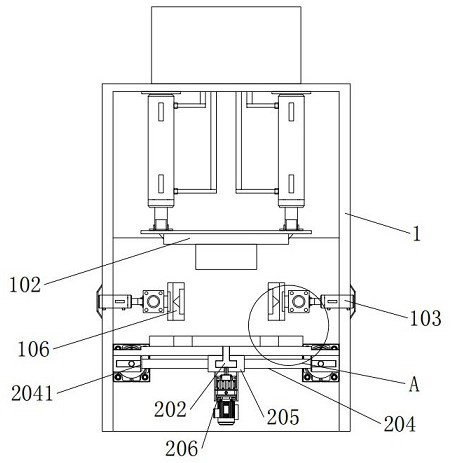

[0037] A hydraulic forging device for forging metal parts, comprising a frame 1, the frame 1 is a "冂"-shaped structure, the inner top of the frame 1 has four hydraulic cylinders 101 in a rectangular array, and the bottom of the hydraulic cylinder 101 is fixed An upper mold 102 is connected, a support table 2 is fixedly installed directly under the frame 1, a lower mold 201 is assembled on the top of the support table 2, the lower mold 201 is arranged in parallel with the upper mold 102, and a protective plate 3 is hinged on the front of the rack 1. , the front of the protective plate 3 is fixedly connected with the controller 301, and the height of the protective plate 3 is greater than the length of the working stroke of the hydraulic cylinder 101;

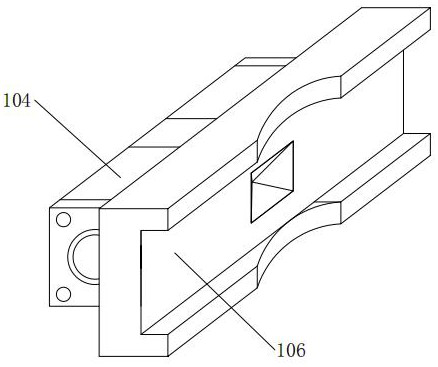

[0038] The forging device used for forging metal parts also includes: the support table 2 and the lower die 201 are rotatably connected through the rotating shaft 202, the front end of the lower die 201 is provided with two horizo...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that: the length of the support table 2 is three times the length of the frame 1, the frame 1 is nested in the outer middle position of the support table 2, and the inner center of the support table 2 is provided with a sliding grooves, slide rails 203 are installed on both sides of the bottom of the support table 2;

[0043] The openings of the slide rails 203 are arranged opposite to each other, and the interior of the slide rail 203 is embedded with a connecting column 204, and the opposite ends of the two connecting columns 204 are fixedly installed with a limit block 205, and the limit block 205 is sleeved on the outer side of the rotating shaft 202;

[0044] The rotating shaft 202 is in an inverted "T" shape, the bottom of the limit block 205 is fixedly connected with a servo motor one 206, and the output end of the servo motor one 206 is connected to the rotating shaft 202 by transmission through a reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com