Automatic assembly control system for power device

An automatic assembly and power device technology, applied in the direction of assembly machines, manufacturing tools, transportation and packaging, etc., can solve the problems of too many pyrotechnics assembly personnel, long assembly preparation time, and many manual operation errors, etc., to achieve safe and reliable information Automated assembly operations, safe and reliable tightening operations, and solutions to the effects of long preparation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0029] This embodiment provides an automatic assembly control system for a power plant, which can realize efficient, accurate, safe and reliable information-based automatic assembly operations.

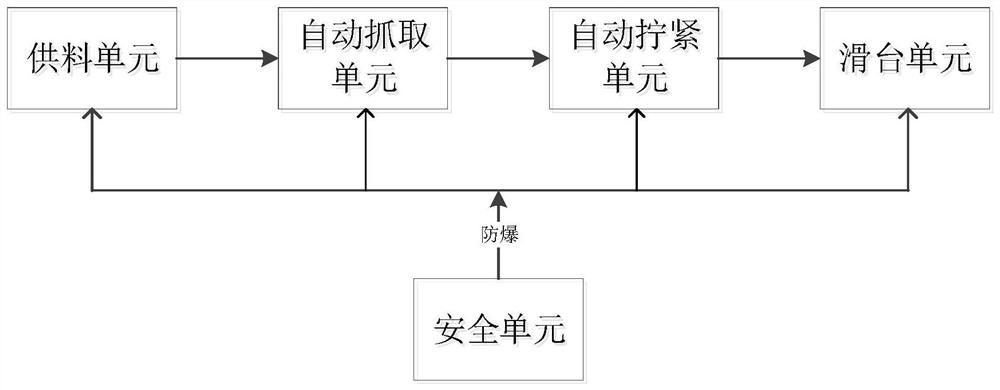

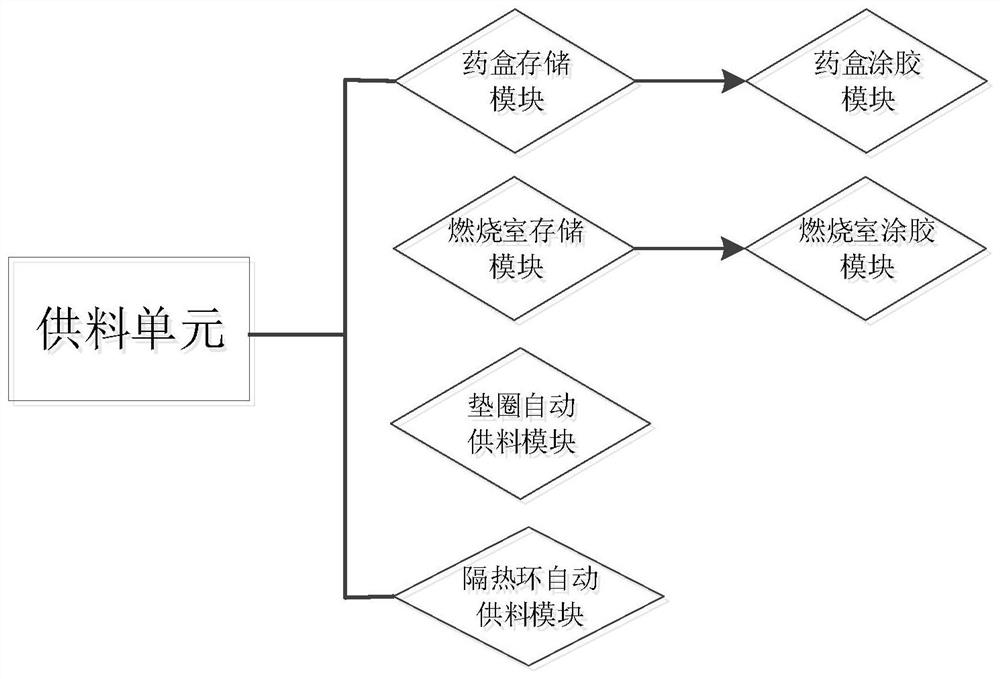

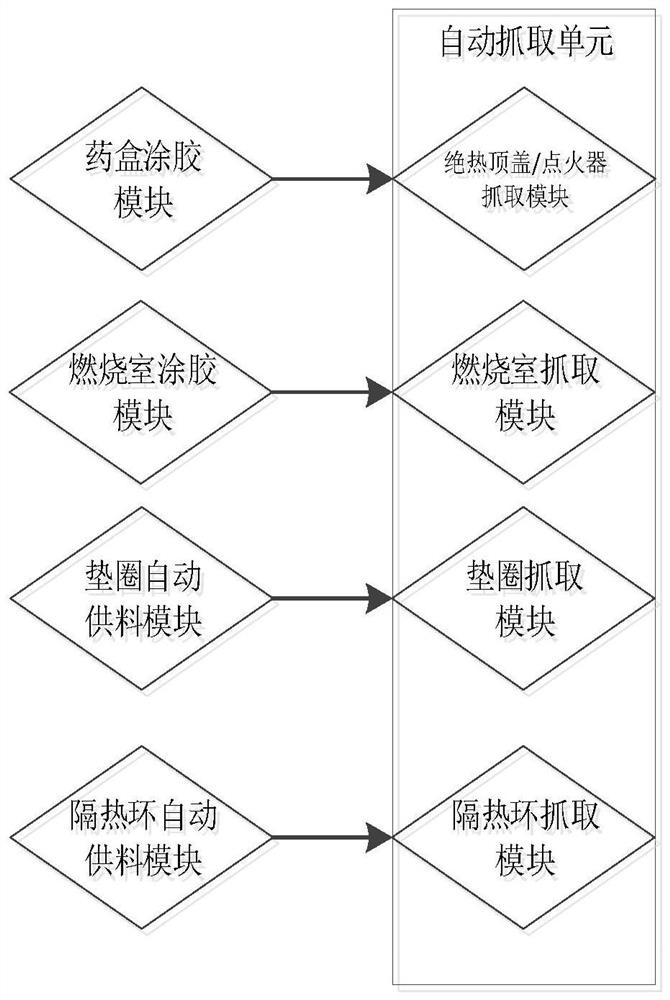

[0030] like figure 1 As shown, the system includes: a feeding unit, an automatic grasping unit, an automatic tightening unit, a sliding table unit and a safety unit; wherein, the feeding unit is responsible for providing raw materials for the automatic grasping unit (the raw materials are the main structural components that make up the power unit) ), the automatic grabbing unit is responsible for grabbing raw materials from the feeding unit and transferring them to the automatic tightening unit, and the automatic tightening unit is responsible for receiving the raw materials grabbed by the automatic grabbing unit and performing different angles and torques on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com