Locking device for workpiece suitable for machining on machine tool

A technology for locking devices and workpieces, applied in positioning devices, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of reducing the useful diameter of pins, reliability and life limitations, and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

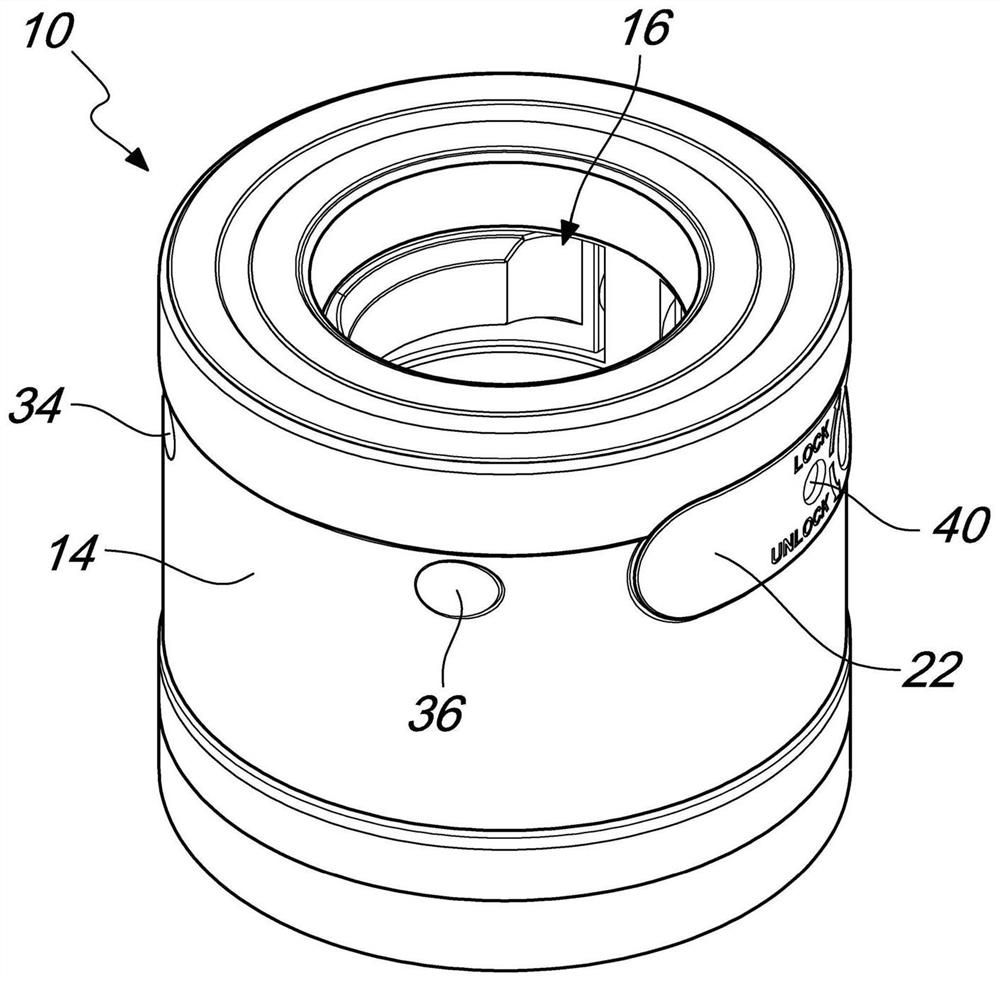

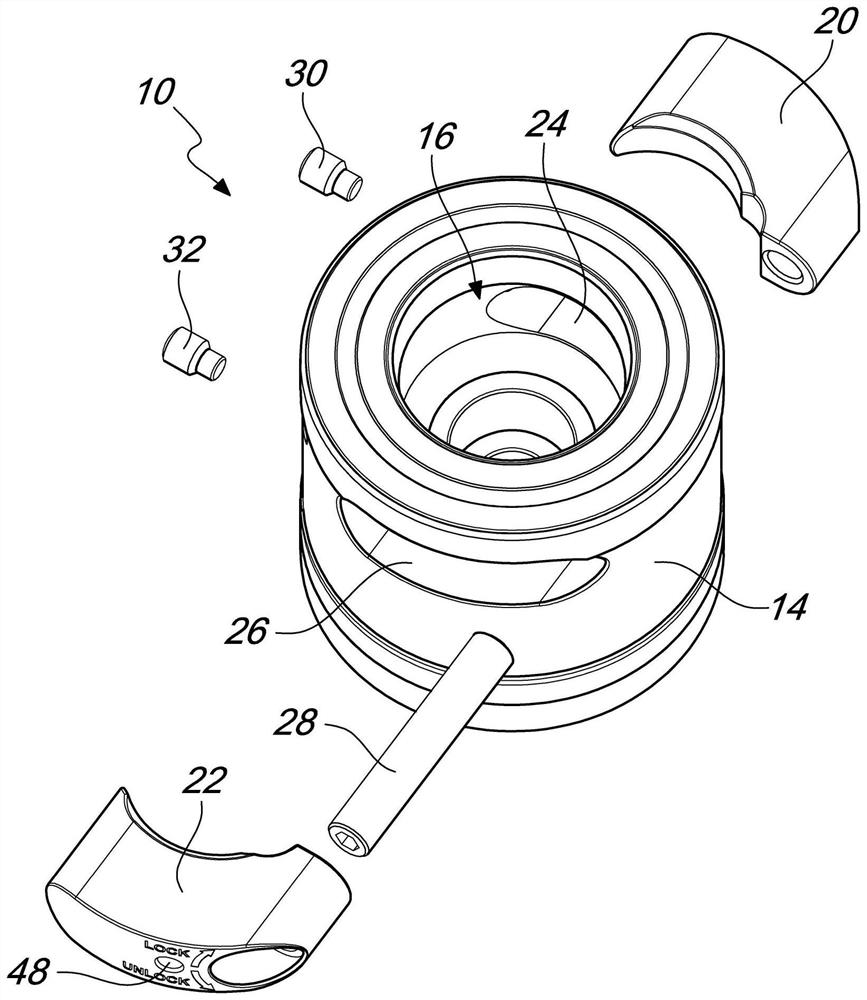

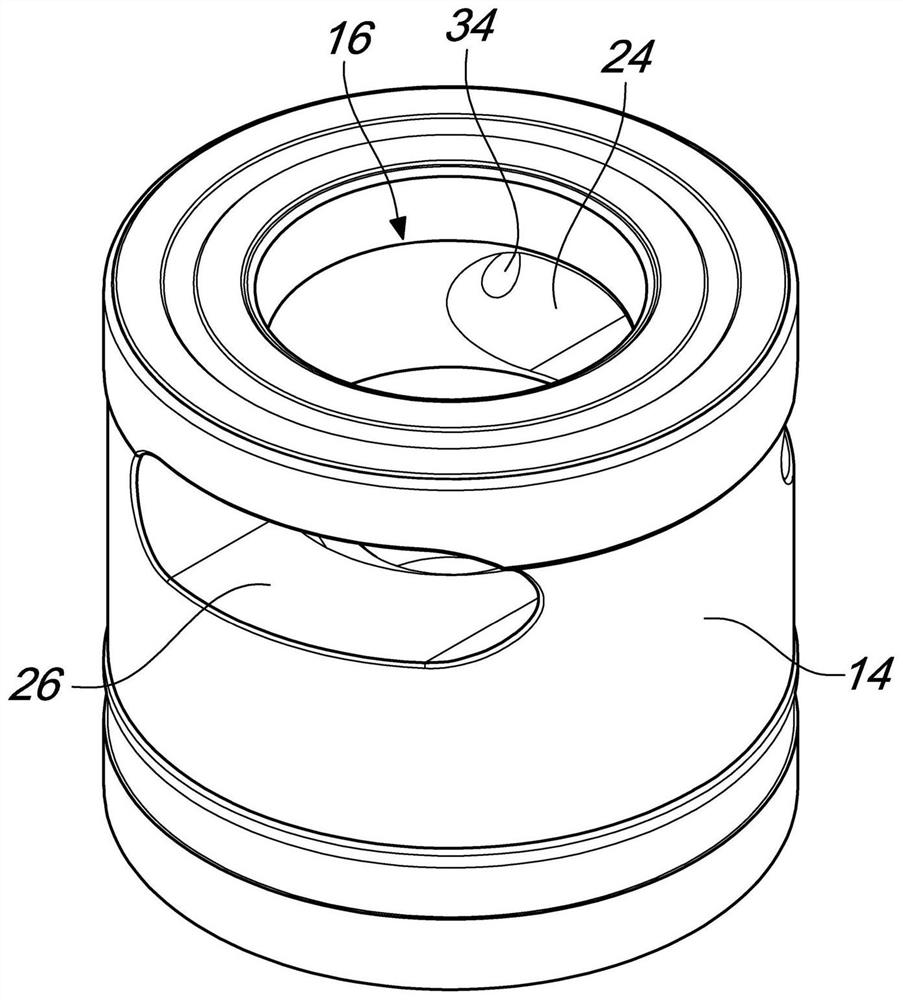

[0027] With reference to the drawings, reference numeral 10 generally designates a locking device for a workpiece obtained, suitable for machining on machine tools and machining centers.

[0028] Specifically, first refer to Figure 13 , a series of locking devices 10 (eg, four locking devices) can be used to position and lock the universal workpiece W in place on a platform P that is mounted in the work area (not shown) of the machine tool and that is conventionally A grid with threaded openings O is provided.

[0029] Each of the locking devices 10 is adapted to receive and retain a pin 12 secured to the workpiece W. In a manner conventional per se, the pin 12 may be hollow and fixed to the workpiece W by a first screw S1 inserted in the pin 12 and screwed into a threaded hole H previously made in the workpiece W.

[0030] The locking device 10 includes a support 14 ( Figure 5 , Figure 11 and Figure 13 ), the support has an axial cavity 16 for receiving the pin 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com