Polishing and brushing machine control method and device, computer equipment and storage medium

A control method and brush grinding machine technology, applied in the direction of grinding device, grinding drive device, grinding/polishing equipment, etc., can solve the problems of workpiece wear and other problems, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present application will be further described in detail below with reference to the accompanying drawings.

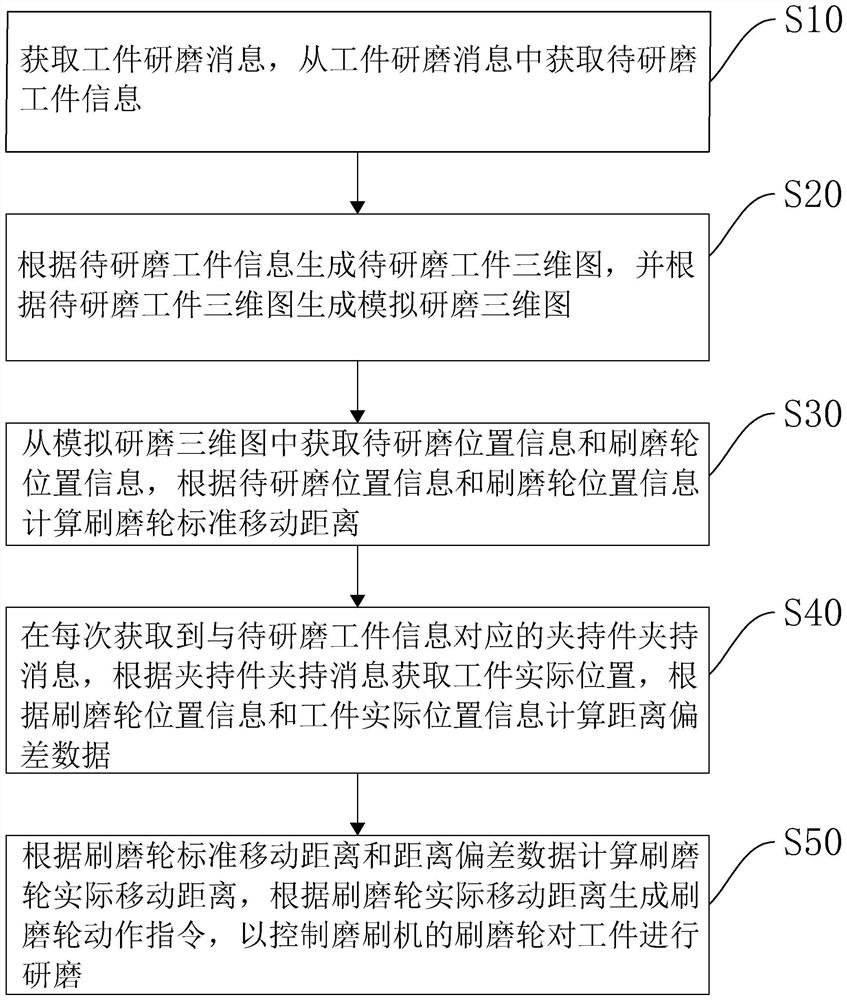

[0056] In one embodiment, as figure 1 As shown, the present application discloses a brushing machine control method, which specifically includes the following steps:

[0057] S10: Acquire the workpiece grinding message, and obtain the workpiece information to be ground from the workpiece grinding message.

[0058] In this embodiment, the workpiece grinding message refers to an instruction message that needs to use a brush grinder to start grinding a batch of workpieces. The workpiece information to be ground refers to information such as the shape, size, and model of the workpiece to be ground.

[0059] In the prior art, when a batch of workpieces are ground by a brush grinder, since the specific position of the workpiece during grinding in the brush grinder cannot be obtained, the first workpiece in the batch needs to be used as an adjustment plate , used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com