Rotary welding test equipment

A test equipment and rotary technology, which is applied in the field of rotary welding test equipment, can solve the problems of being unable to meet the requirements of empty cup body testing and single testing process, and achieve the effect of improving test flexibility and flexible replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

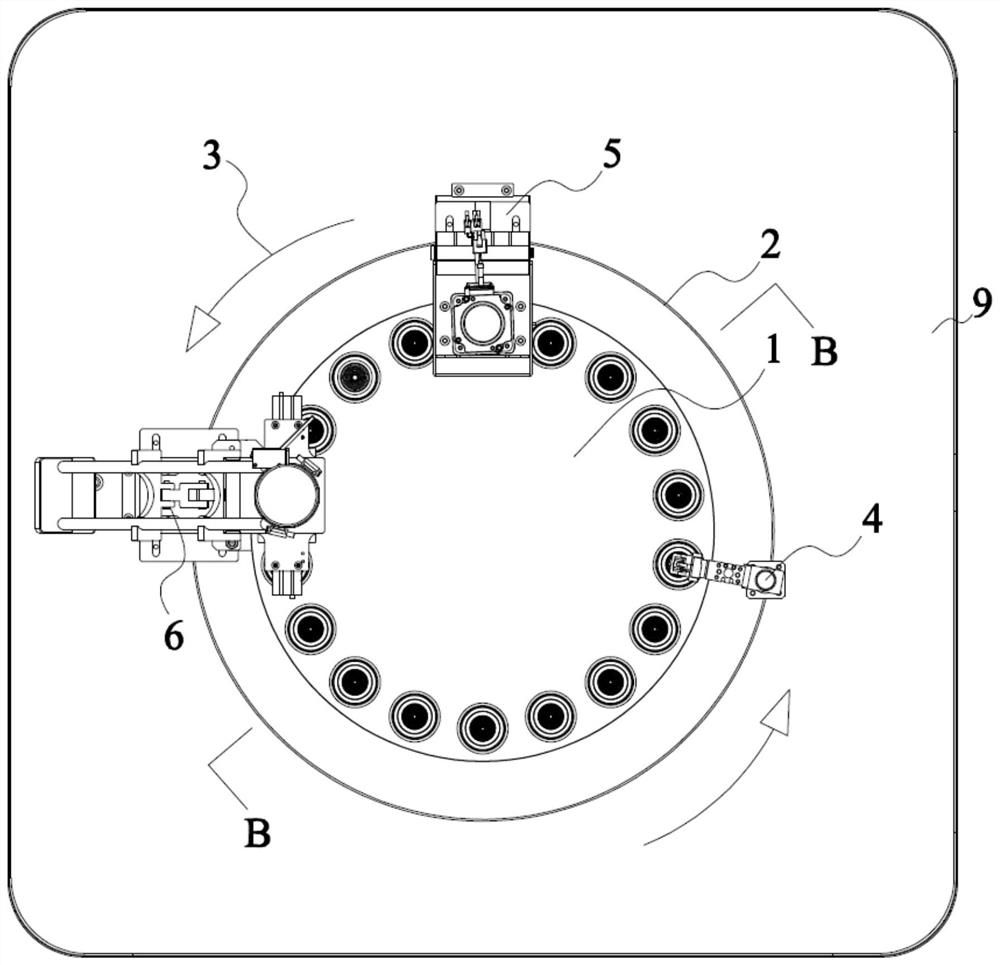

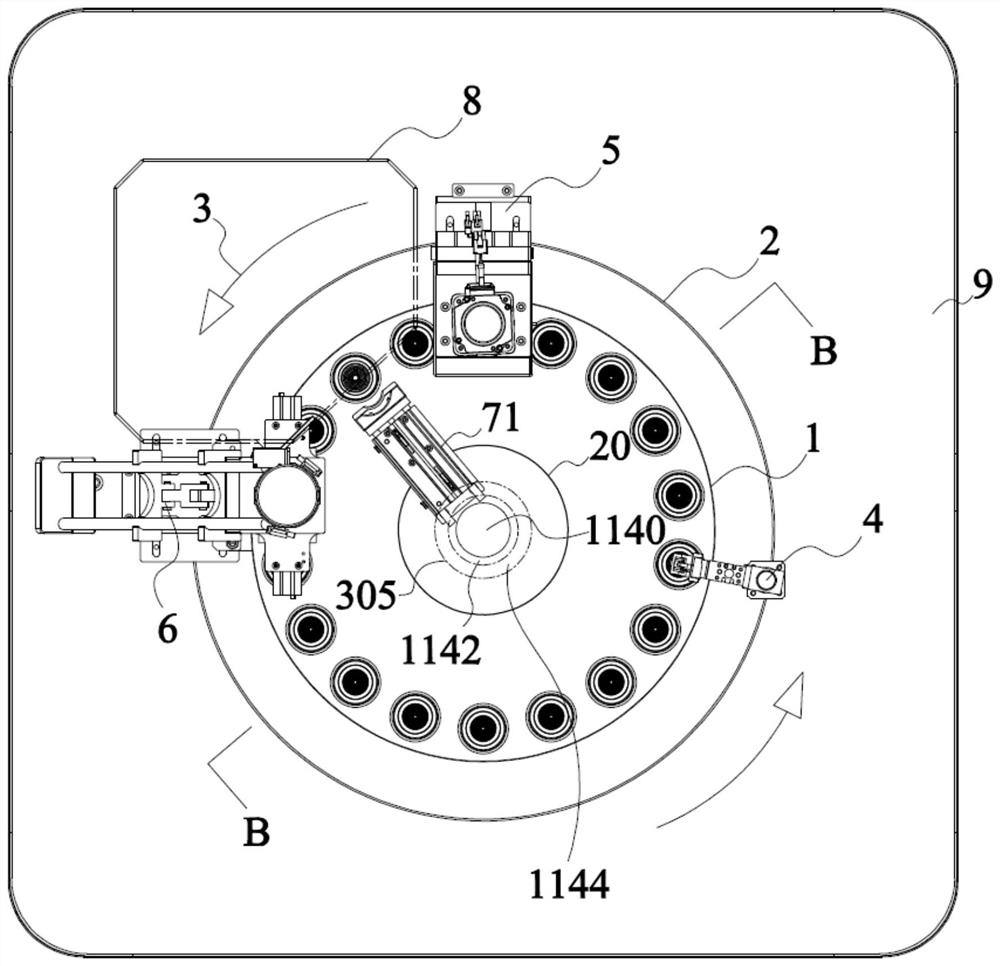

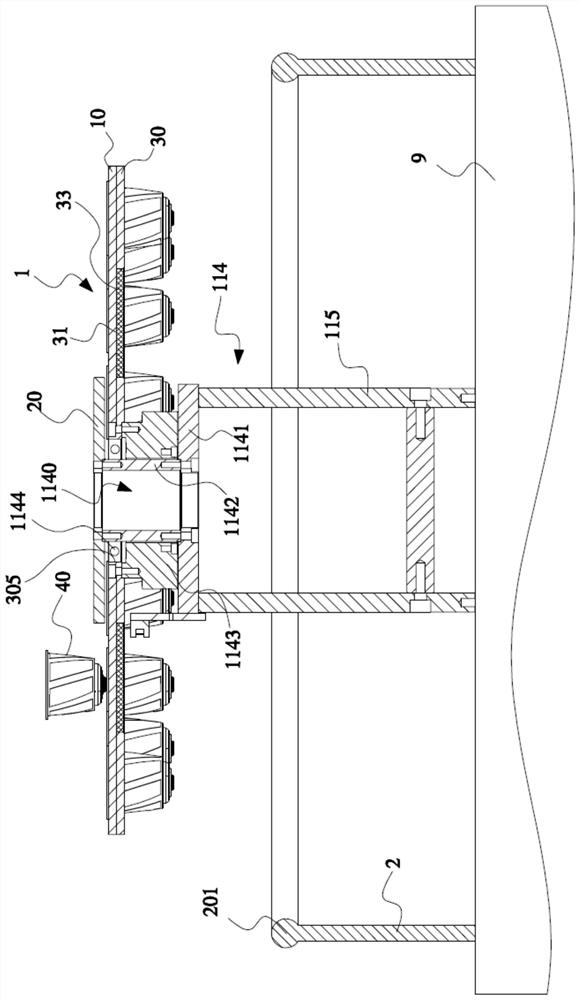

[0037] ginseng Figure 1 to Figure 11 A specific embodiment of a rotary welding test apparatus of the present invention is disclosed.

[0038] A rotary welding test equipment disclosed in this embodiment (hereinafter referred to as "" Test Equipment ”), including: a rotating disc 1, a guide ring 2 arranged on the outside of the rotating disc 1, and at least one ultrasonic welding device 5 guided by the guiding ring 2. The ultrasonic welding device 5 is provided with embedded The drive base 51 that guides the ring 2 and moves along the guide ring 2, the rotating disk 1 includes a base plate 30 and a number of detachable mounting pieces that are detachably fitted and installed on the surface of the base plate 30. The ultrasonic welding device 5 actively moves along the guide ring 2 Moved or moved manually, the rotating disc 1 is set on the bracket 114 and kept fixed. Combination image 3 As shown, the guide ring 2 can be vertically arranged above the machine 9 as a whole, and...

Embodiment 2

[0053] ginseng Figure 12 As shown, this embodiment discloses another specific implementation of the rotary welding test equipment.

[0054] The main difference between the test equipment disclosed in this embodiment and the first embodiment is that, in this embodiment, a plurality of detachable mounting pieces 10a attached to the upper surface of the chassis 30 are directed toward the center of the chassis 30. The end portion 111 is inserted laterally under the center plate 20a, so that the center plate 20a and the chassis 30 clamp the removable mounting piece 10a up and down and point to the end portion 111 formed by the center of the chassis 30. The center plate 20a laterally covers the end 111 formed by clamping the removable mounting piece 10 toward the center of the chassis 30 . The rotating disk 1 disclosed in this embodiment can simultaneously impose lateral restraints and vertical downwards on the circular arc surfaces 112 formed by the ends 111 of the plurality of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com