Method for repairing formed tire blank to improve UFDB performance of tire

A tire and tire embryo technology is applied in the field of forming tire embryo repair to improve tire UFDB performance. Unqualified appearance repair, improvement of UFDB performance, effect of improving UFDB performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

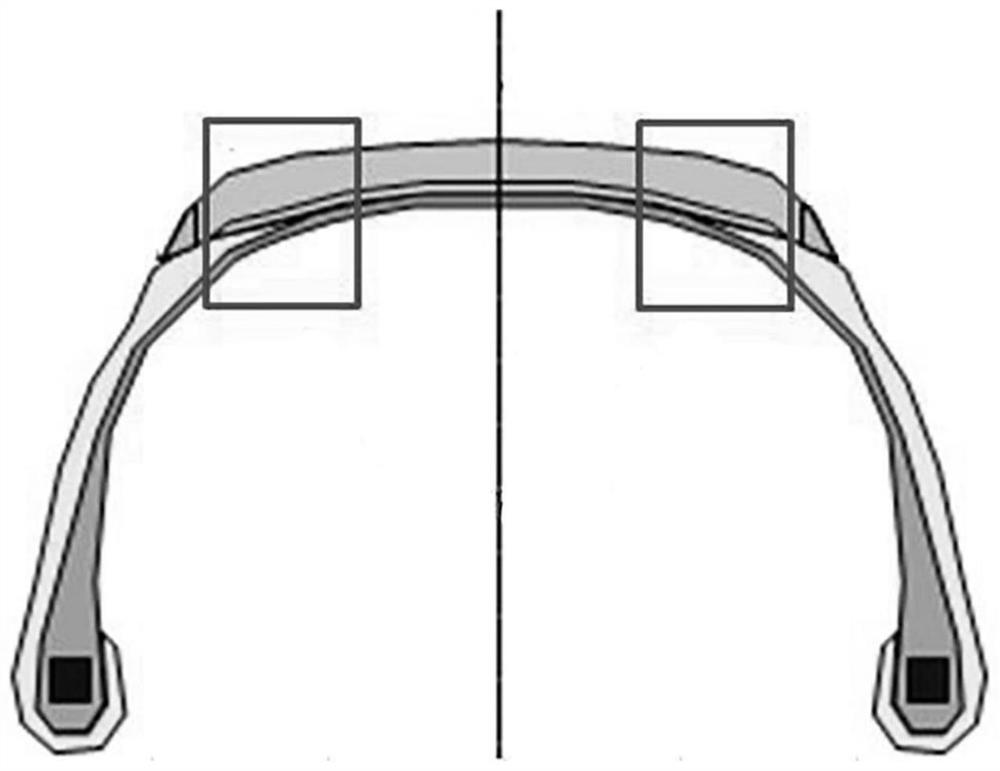

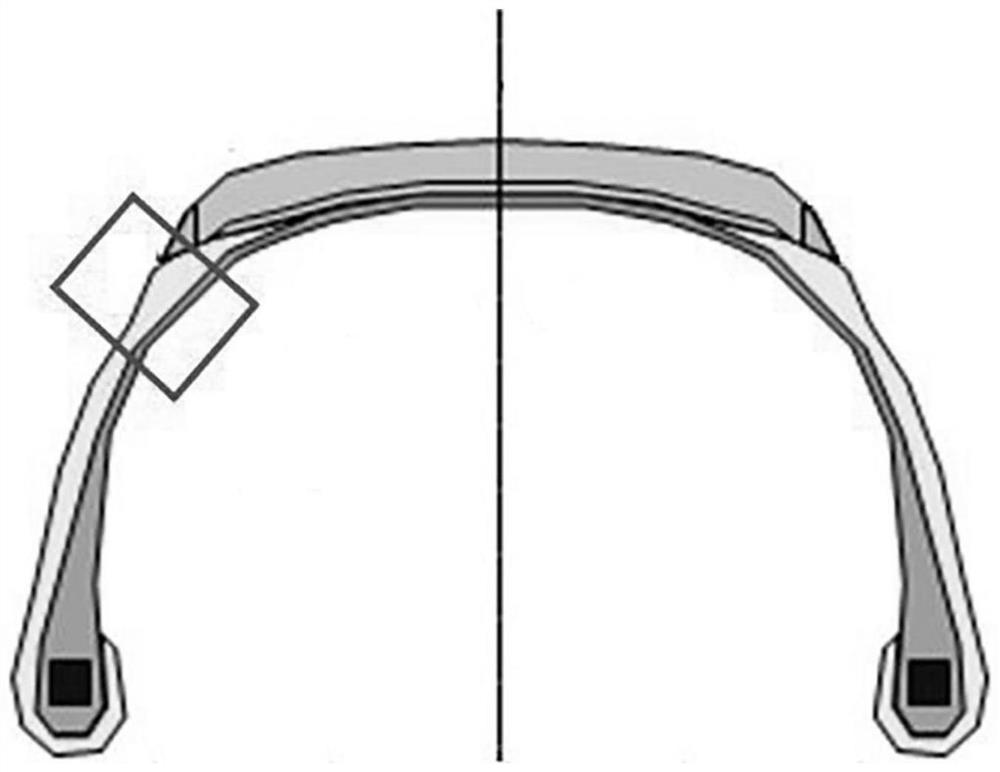

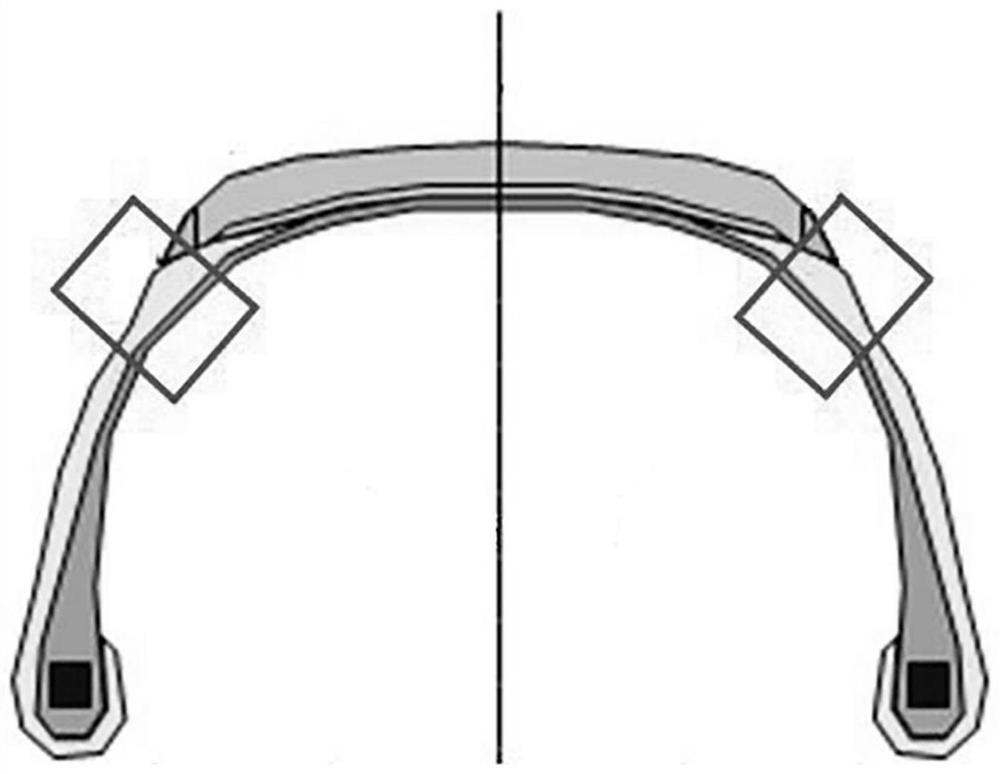

[0035] The present embodiment provides a method for improving the UFDB performance of a tire by repairing a shaped embryo. By repairing the shaped embryo before the tire is vulcanized, the UFDB performance of the finished tire after vulcanization is improved, and the method includes the following steps:

[0036] Step S1: Use the UF uniformity tester and the DB dynamic balance tester to test the UFDB performance of the unvulcanized tire blank, and through the analysis of the test results, count the characteristics of the unqualified tire, including the unqualified detection value of the RFV and the dot position, CON The unqualified detection value and the positive and negative of the detection value, the STATIC unqualified detection value and the detection dot position.

[0037] Step S2: Judging according to the statistical characteristics of unqualified tires, and repairing the unqualified tire blanks. The film used for repair is consistent with the rubber material at the posit...

Embodiment 2

[0044] The method for repairing the UFDB tires provided by the present invention is suitable for batch repairing of unqualified batches of tires. The steps are as follows: Figure 4 As shown in the flow chart, including:

[0045] (1) UFDB detects the molded embryos of the same shift and the same specification, and if 3 unqualified tests occur, the vulcanization process will be reported to stop vulcanization, and the reasons for the unqualified tires will be investigated;

[0046] (2) UFDB detects unqualified tire characteristic statistics, including the unqualified value and dot distribution, such as RFV unqualified need to count the test value and dot position, CON unqualified need to count the test value and the positive and negative of the test value, STATIC unqualified It is necessary to count the detection value and the detection point position;

[0047] (3) The repair methods for tires that fail to pass the RFV, CON, and STATIC tests are as follows:

[0048] (3.1) Bad ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com