Full-automatic packaging machine for automatic processing

A fully automatic packaging machine and packaging box technology, applied in packaging machines, packaging, packaging protection and other directions, can solve the problems of increasing equipment cost and maintenance difficulty, and achieve the effect of simplifying operation and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

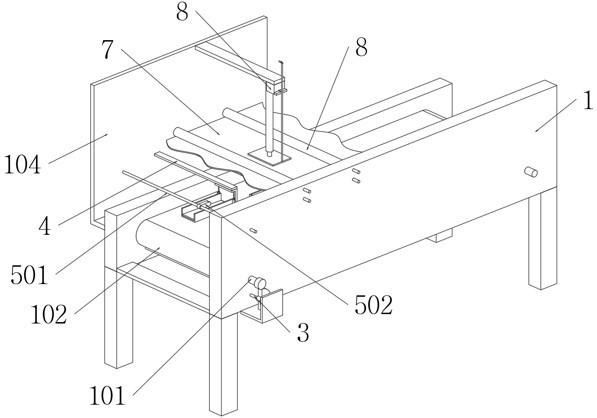

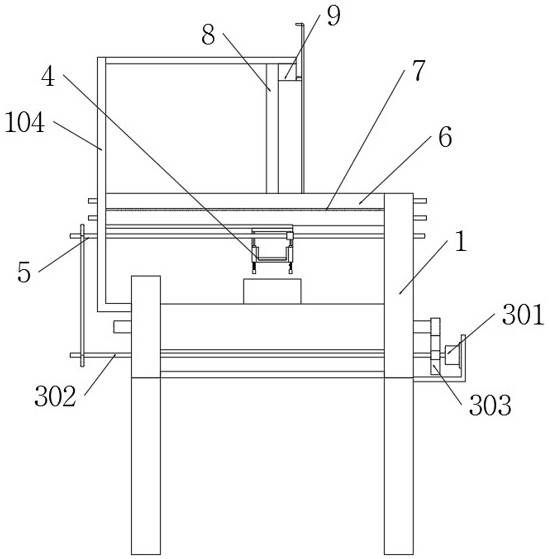

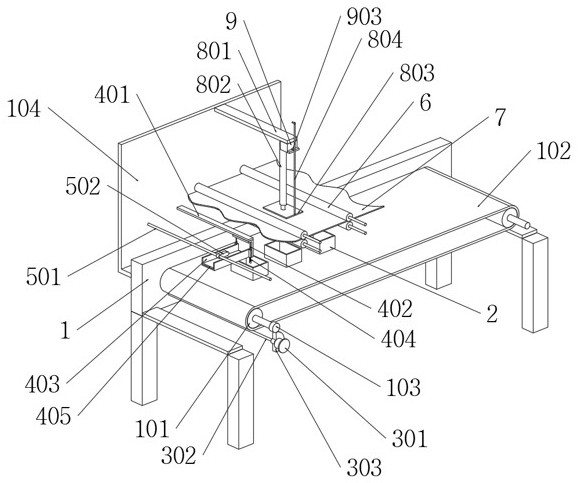

[0044] Example: please refer to Figure 1 to Figure 8 :

[0045] The present invention provides a fully automatic packaging machine for automatic processing, comprising: an assembly line frame body 1, a first driving part 3, a storage part 4, a second driving part 5 and a packaging part 8;

[0046] Two conveying rollers 101 are rotatably connected to the assembly line frame body 1, and a conveying belt 102 is sleeved on the two conveying rollers 101, and a packaging box 2 is conveyed on the conveying belt 102;

[0047] A mounting plate 104 is fixedly connected to the assembly line frame body 1 by bolts, and a transport roller 6 is mounted on the mounting plate 104, and the transport roller 6 is transported with a packaging film 7;

[0048] The first driving part 3 is composed of a driving motor 301, a rotating shaft A302, an incomplete gear 303 and a pulley A304, and the driving motor 301 is fixedly connected to the assembly line frame body 1 by bolts;

[0049]The storage pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com