Belt air compressor with efficient heat dissipation function

An air compressor and belt technology, applied in mechanical equipment, machine/engine, dispersed particle separation, etc., can solve the problems affecting the normal operation of the belt air compressor and the large heat of the belt air compressor, so as to facilitate the collection and cleaning, improve the Heat dissipation function, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

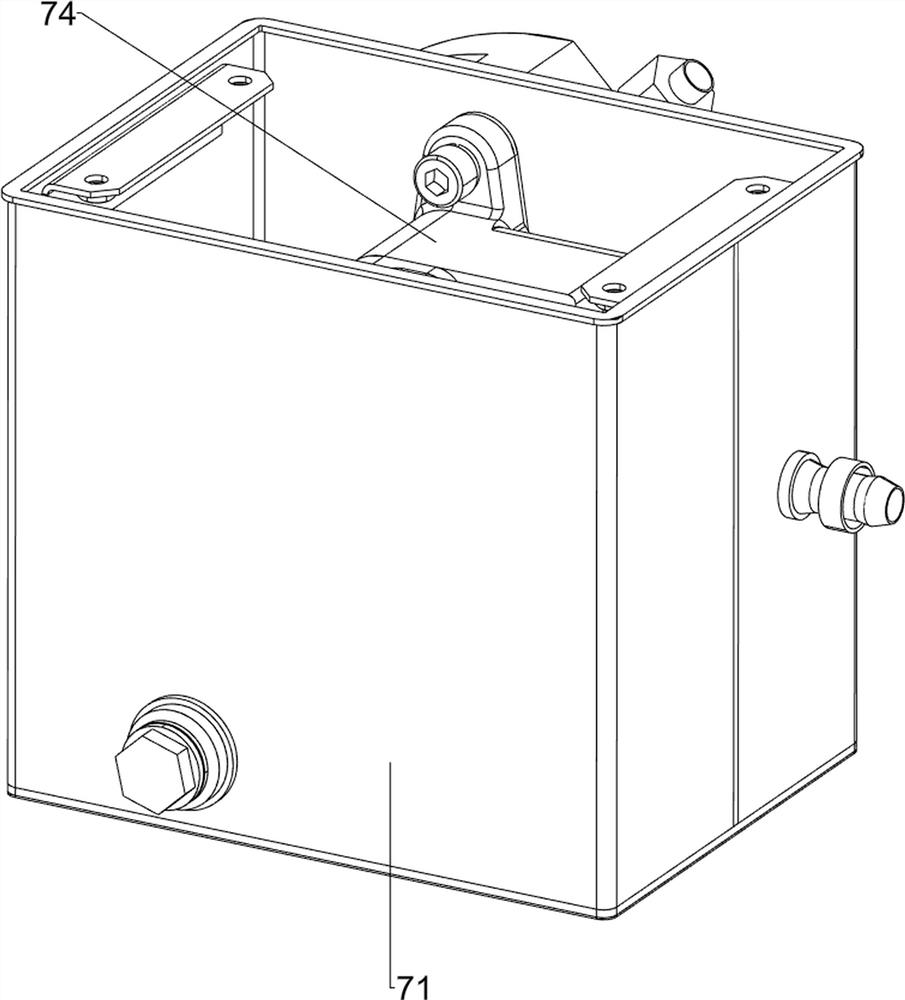

[0038] A belt air compressor with efficient heat dissipation, including a base 1, a fixed frame 2, a gasoline engine 3, a transmission mechanism 4, a blowing mechanism 5, a material storage mechanism 6 and a cooling mechanism 7, see Figure 1-Figure 11 As shown in the figure, the number of bases 1 is four, a fixed frame 2 is welded between the top of the base 1, and a gasoline engine 3 is bolted on the left side of the lower part of the fixed frame 2. The gasoline engine 3 is turned on to provide the belt air compressor with efficient heat dissipation. To provide power, the lower part of the fixing frame 2 is provided with a transmission mechanism 4; Institution 7.

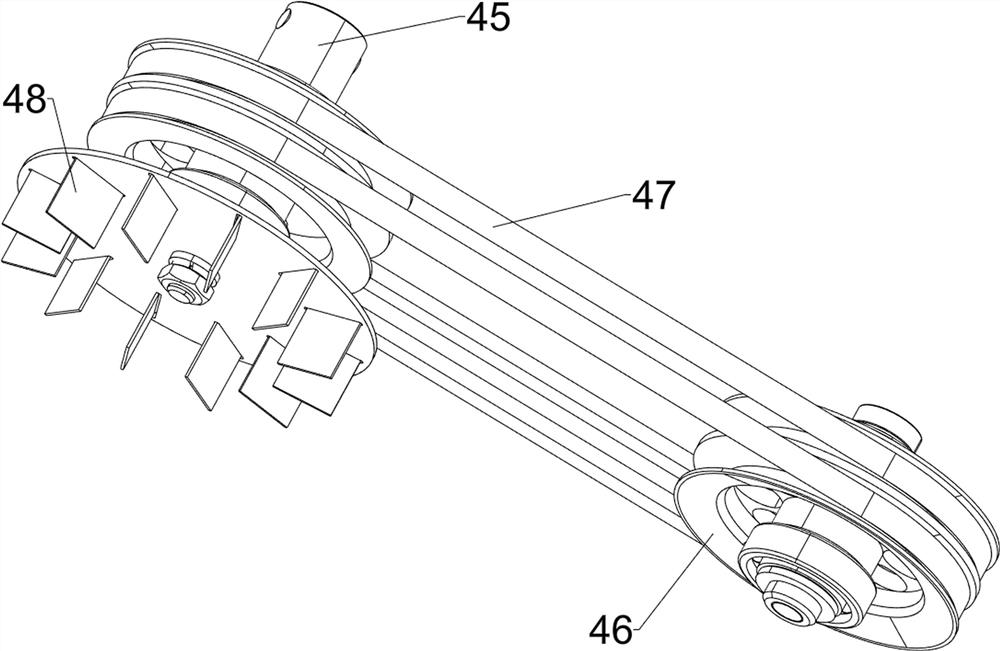

[0039] The transmission mechanism 4 includes a first mounting frame 41, a second mounting frame 42, a cover plate 43, an outer cover 44, a rotating rod 45, a transmission wheel 46, a belt 47 and an impeller 48, see figure 2 , image 3 and Figure 4As shown in the figure, a first mounting bracket 41 is welded o...

Embodiment 2

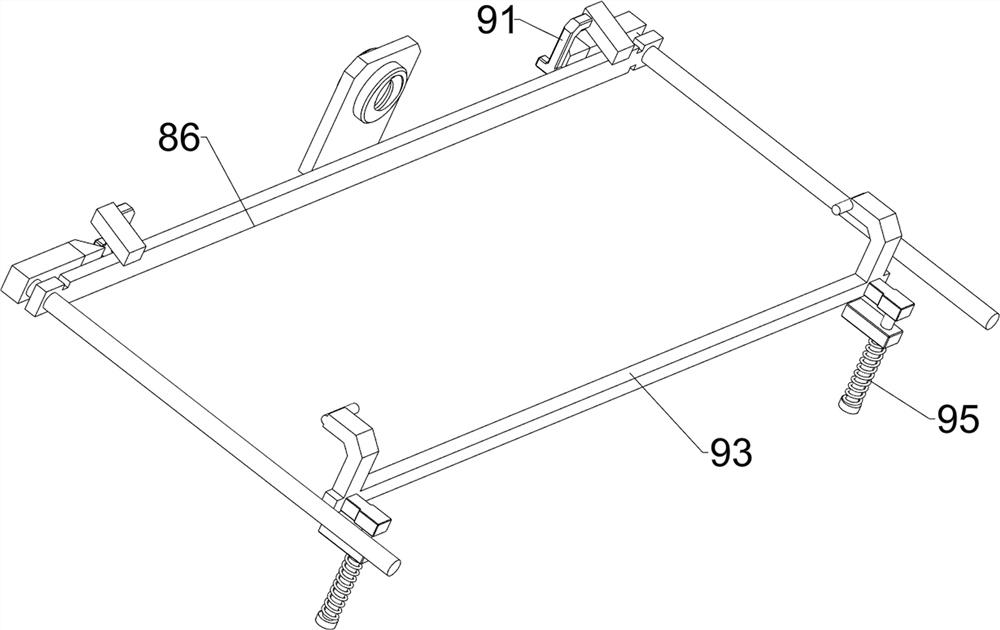

[0045] On the basis of Embodiment 1, a heat dissipation mechanism 8 is also included. The heat dissipation mechanism 8 includes a first connecting plate 81 , a heat dissipation fin 82 , a fan 83 , a filter screen 84 , a motor 85 , a first scraper 86 and a screw rod 87 . , see figure 1 and Figure 12 As shown, a first connecting plate 81 is welded on the lower right front of the fixing frame 2, the third conduit 72 passes through the upper part of the first connecting plate 81, the upper right side of the first connecting plate 81 is provided with a cooling fin 82, and the third conduit 72 Passing through the heat sink 82, fans 83 are bolted on both the front and rear sides of the upper inner side of the first connecting plate 81. When the fans 83 are turned on, the third duct 72 can be blown, thereby cooling the water in the third duct 72. The upper left side of the first connecting plate 81 is provided with a filter screen 84, the top left middle of the first connecting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com