Rubbing experiment table for multi-disc bolt connection rotor and testing method thereof

A test bench and rubbing technology, applied in vibration testing, impact testing, engine testing, etc., can solve the problem that the research on the performance change of the connection structure is not common, and achieve the effect of precise adjustment, stability and reliability, and guaranteeing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and technical solutions.

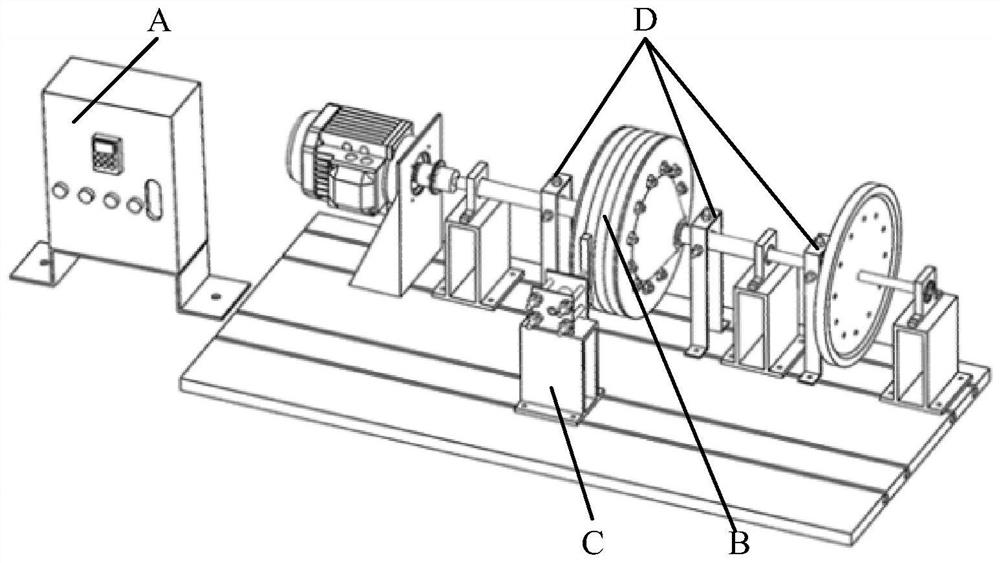

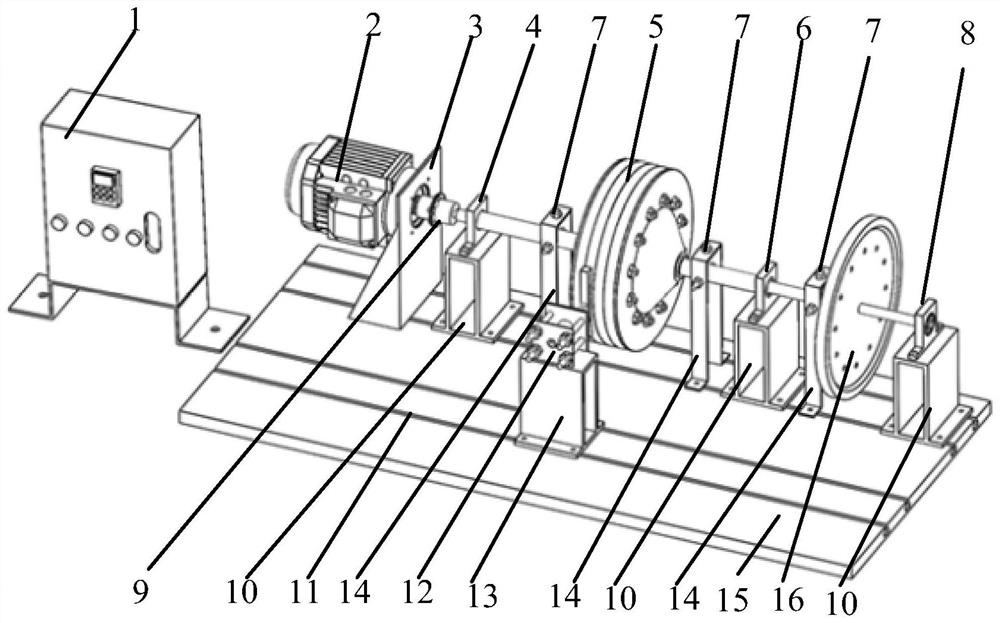

[0050] like figure 1 , 2 As shown, a multi-disk bolted rotor rubbing test bench is mainly composed of an electrical drive and control system A, a high-pressure rotor system B, a rubbing system C, a test sensing system D and a base 15 .

[0051] The base 15 is installed with a plurality of bolts for fixing the motor bracket 3, the bearing seat bracket 10, the eddy current sensor bracket 14 and the rubbing device bracket 13; at the same time, there are slide rails 11, which are used for the axial direction of the rubbing system. move.

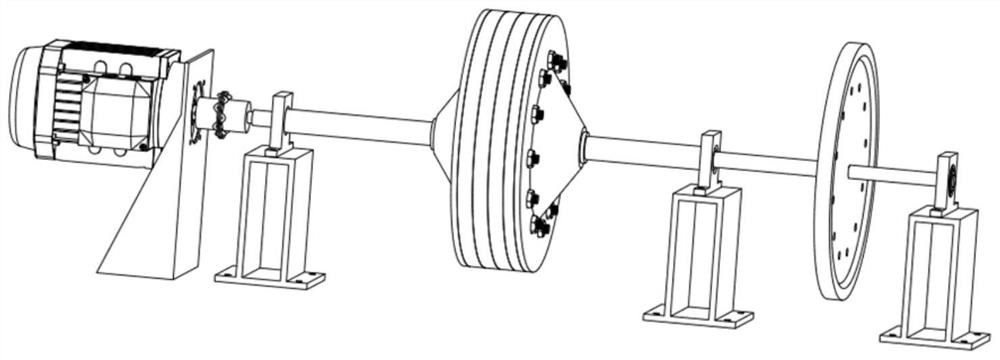

[0052] like image 3 As shown, the high-pressure rotor system B includes mainly a rotating shaft, a multi-disk-hub-bolt connection structure 5, a high-pressure turbine disk 16, a bearing seat bracket 10, a first bearing and a bearing seat 4, a second bearing and a bearing seat 6 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com