Assembly comprising a rotating wheel made of non-magnetic

A technology of non-magnetic materials and rotating wheels, which is applied in the field of watches and clocks, and can solve problems such as the influence of movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] As mentioned above, the present invention relates to an assembly comprising a rotating wheel and a bearing, such as a jewel, especially for a timepiece. The gemstone is intended to be in contact with the pivot of the rotating wheel to allow the pivot to rotate with minimal friction. However, such an assembly is not limited to the field of timepieces, and can be applied to any component that is rotatably mounted relative to the bearing.

[0069] The gemstone is preferably formed from alumina or zirconia having a crystal structure of the monocrystalline or polycrystalline type. The gemstones form guide elements intended, for example, to be installed in shock absorber bearings of timepieces.

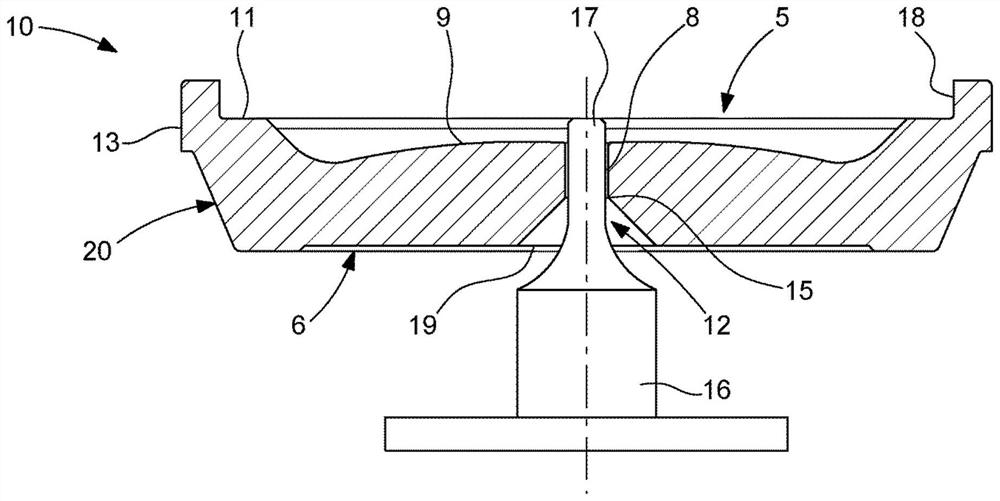

[0070] exist figure 2In it, a hole 8 intended to receive a pivot 17 (also called a trunnion) penetrates the jewel 20 of the assembly 10 . The gemstone 20 includes an upper surface 5 and a lower surface 6 , one of which includes a tapered portion 12 communicating with the through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com