GaN-based LED epitaxial structure, preparation method thereof and light-emitting diode

An epitaxial structure, methyl gallium technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of decreasing the luminous efficiency of light-emitting diodes, increasing the resistivity of P-type GaN, increasing the forward voltage of light-emitting diodes, etc. The effect of reducing content, reducing resistivity and easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

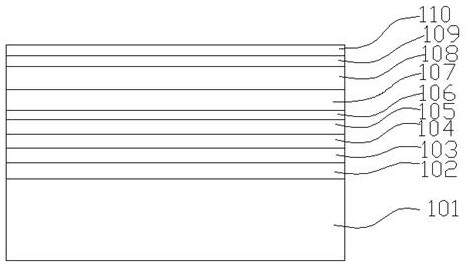

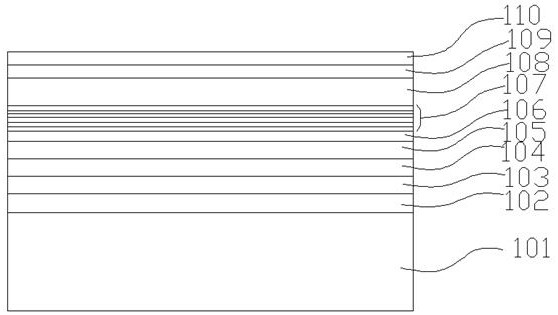

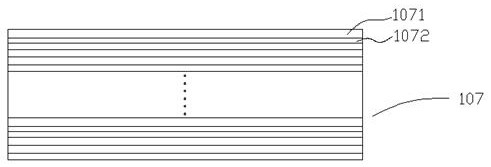

[0021] This embodiment provides a GaN-based LED epitaxial structure, such as figure 2 As shown, it includes a substrate, and a buffer layer, a uGaN layer, an nGaN layer, a stress release layer, a quantum well layer, a low temperature pGaN layer, a pALGaN layer, a pGaN layer and a contact layer grown on the substrate in sequence; the low temperature pGaN layer From a trimethylgallium sublayer with a carbon impurity content of 8.0E16 and a carbon impurity content of 2.0E16 Atoms / cm 3 The triethylgallium sublayers are alternately grown for 10 cycles to form. In the low temperature pGaN layer, the total thickness of the trimethylgallium sublayer is 10 nm, and the total thickness of the triethylgallium sublayer is also 10 nm.

[0022] The preparation method of the above-mentioned GaN-based LED epitaxial structure is as follows:

[0023] Step 1, heating the ALN-plated pss substrate 101 to 1000-1200° C. for surface cleaning treatment for 5-10 minutes;

[0024] Step 2, reducing th...

Embodiment approach 2

[0035] This embodiment is exactly the same as Embodiment 1, except that the carbon impurity content of the triethylgallium sublayer in this embodiment is 3.0E16 Atoms / cm 3 .

Embodiment approach 3

[0037] This embodiment is exactly the same as Embodiment 1, except that the carbon impurity content of the triethylgallium sublayer in this embodiment is 5.0E16 Atoms / cm3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap