Self-cooled axial flux motor

An axial magnetic flux, self-cooling technology, used in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of magnetic performance decline of magnetic steel, demagnetization of magnetic steel, deformation of parts, etc., to improve the heat dissipation effect, The effect of reducing parts and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

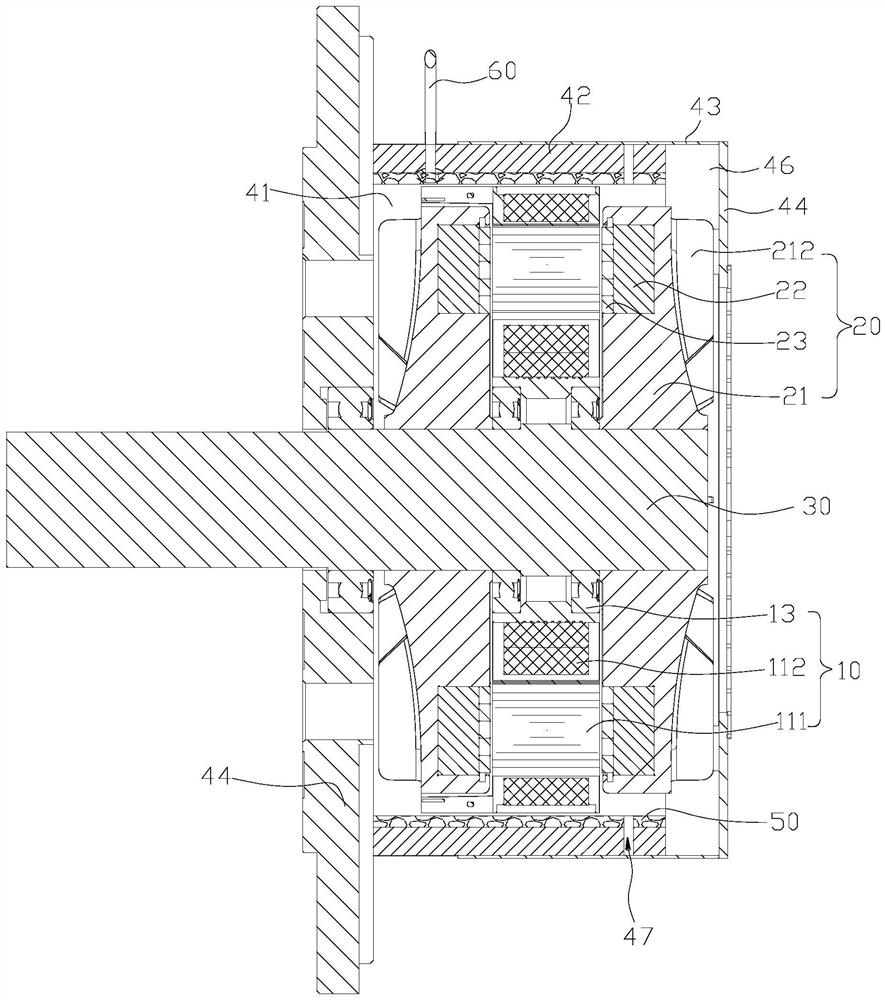

[0035] In order to make the reliability of the rotor more stable, a pressing rod 70 can be arranged at the gap between two adjacent pieces of magnetic steel 23, such as Figure 9-11 , at least one end of the pressing rod 70 is fixed on the rotor back plate 21 , and the shaft of the pressing rod 70 is pressed against the magnetic conducting plate 22 .

[0036] Further explanation is that the pressing rod 70 can be fixed on the rotor back plate 21 at one end, or can be fixed on the rotor back plate 21 at both ends. However, it must be ensured that the shaft of the pressing rod 70 is pressed on the magnetic conducting plate 22 . The specific structure used can be determined according to the diameter of the rotor. Generally, the large diameter rotor is fixed at both ends, while the pressure rod of the small diameter rotor is fixed by one end, and the other end can be overhanging and pressing to meet the fixing requirements. When installing, first put the magnetic conductive plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com