Abrasion testing machine for rotator cuff balloon prosthesis

An experimental machine and balloon technology, which is applied in shoulder joints, testing wear resistance, joint implants, etc., can solve problems such as wear testing of rotator cuff (shoulder joint) balloon prostheses, and achieve the goal of avoiding interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

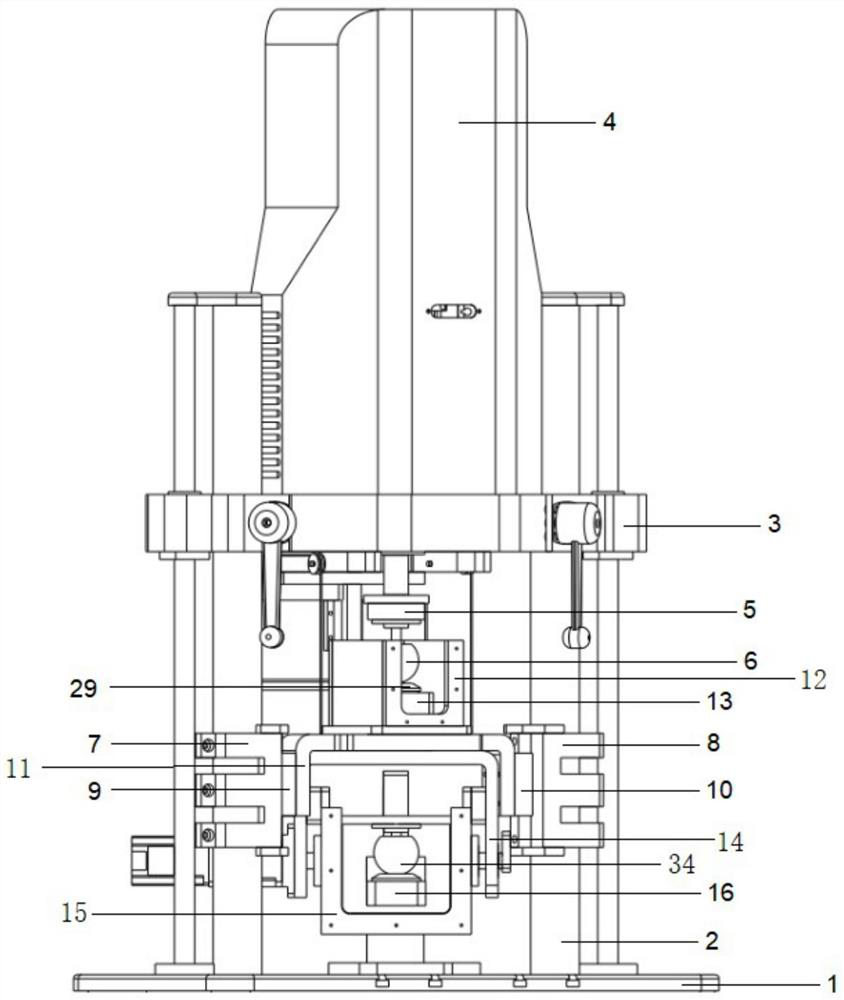

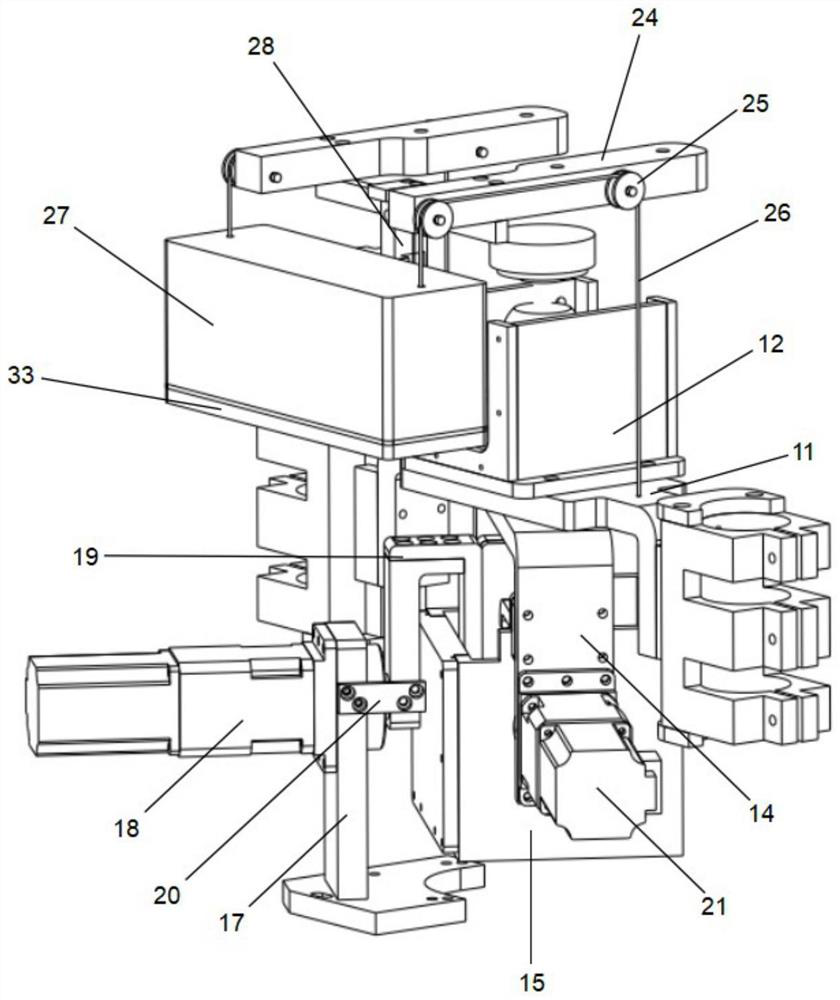

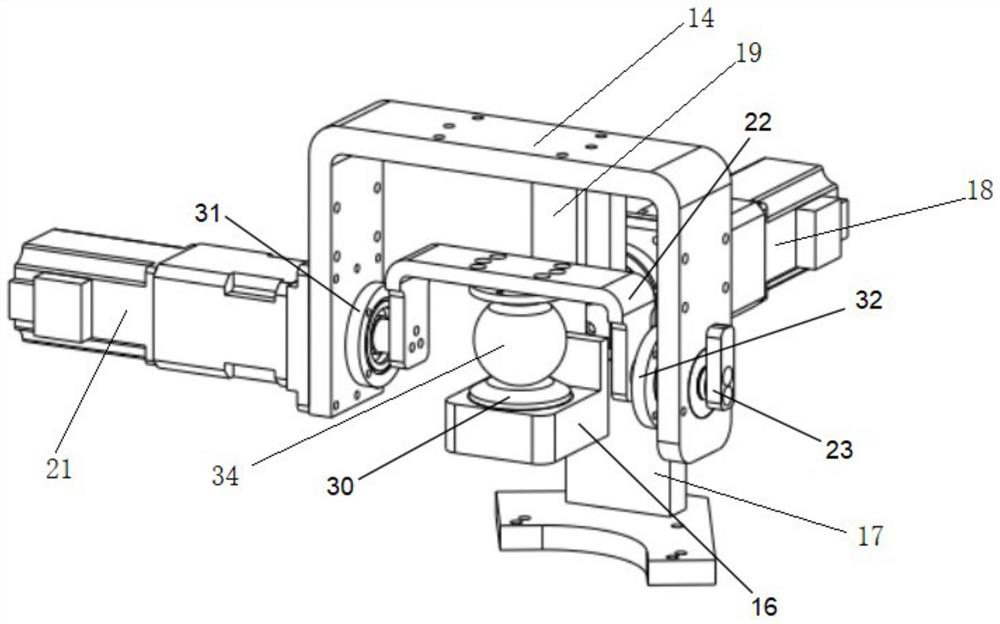

[0042] According to a preferred embodiment of the present invention, see Figure 1-5 , provides a rotator cuff balloon prosthesis wear test machine, which is characterized by comprising:

[0043] a first guide post 2 and a second guide post; and

[0044] The first loading unit is connected to the first guide post 2 and the second guide post and is used to apply the first rotational load in the first direction and the second rotational load in the second direction to the first experimental chamber 15 with the constant temperature liquid Within the experimental group of samples 30, the first direction is perpendicular to the second direction.

[0045] According to yet another preferred embodiment of the present invention, the rotator cuff balloon prosthesis wear testing machine further includes a second loading unit, which is arranged between the first guide post 2 and the second guide post and is used to apply a load in the vertical direction to the Control sample 29 in secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com