Accurate feed mixing control method and feed mixing device

A control method and a technology of a mixing device, which are applied to chemical instruments and methods, mixers with rotating stirring devices, mixers, etc., can solve problems affecting broiler feeding and low accuracy of feed component proportions, and improve feeding efficiency , avoid mixing time is too long, easy to manage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

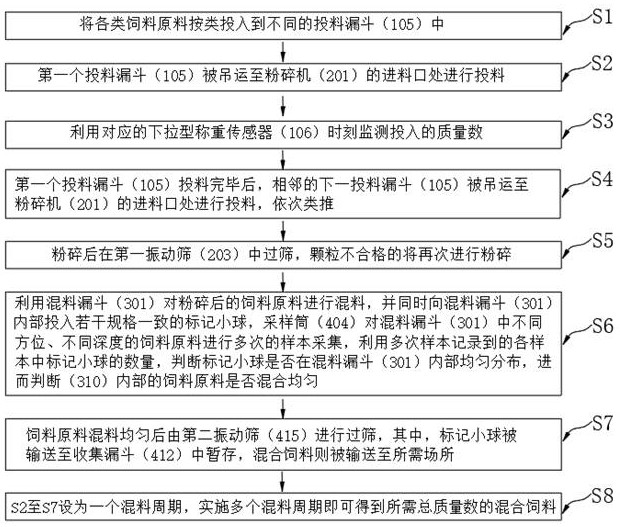

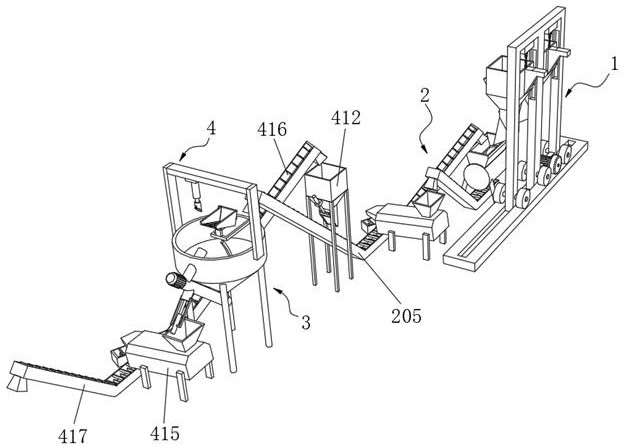

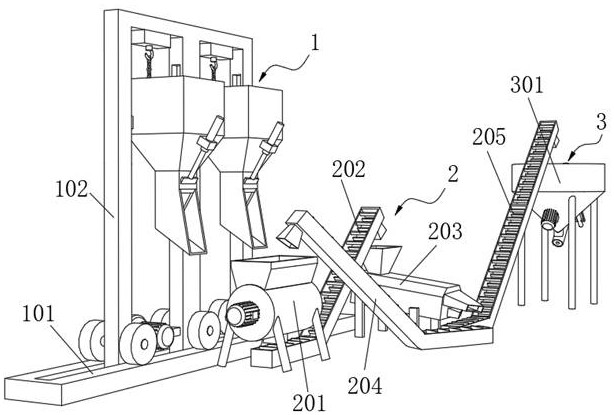

[0045] like Figure 1-12 As shown, the embodiment of the present invention provides a method for precise control of feed mixing, comprising the following steps:

[0046] S1. Put the feed raw materials into different feeding hoppers 105 by category, and use the background control computer to divide all kinds of feed raw materials into the same number of groups according to their total required quality;

[0047] S2. The background control computer controls the gantry 102 to move laterally to lift the first feeding hopper 105 to the feeding port of the pulverizer 201 , and the first hydraulic rod 108 drives the first blocking plate 107 to open the bottom of the feeding hopper 105 for discharging. mouth for feeding;

[0048] S3. When the first feeding funnel 105 in S2 is feeding, the background control computer uses the corresponding pull-down weighing sensor 106 to monitor the input mass at all times, and when the input mass is equal to the mass of each group of feed materials o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com