Partition plate placing device, boxing equipment and filling production line

A partition and equipment technology, applied in the field of filling equipment, can solve the problems of reducing the size of the mechanism, large structure, disadvantages, etc., and achieve the effects of reducing the overall size, improving stability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

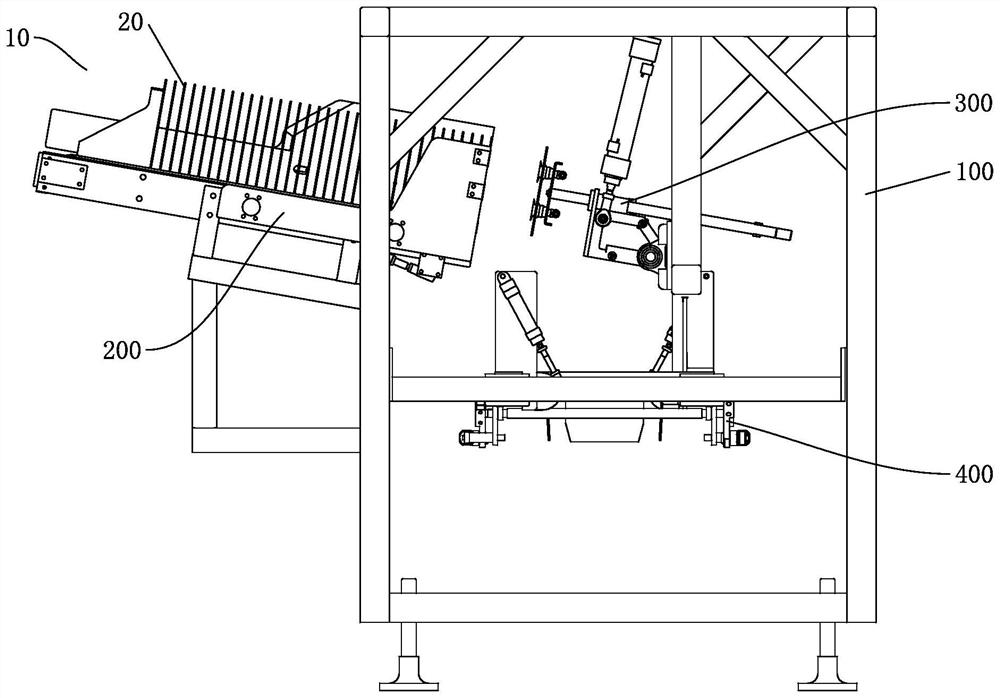

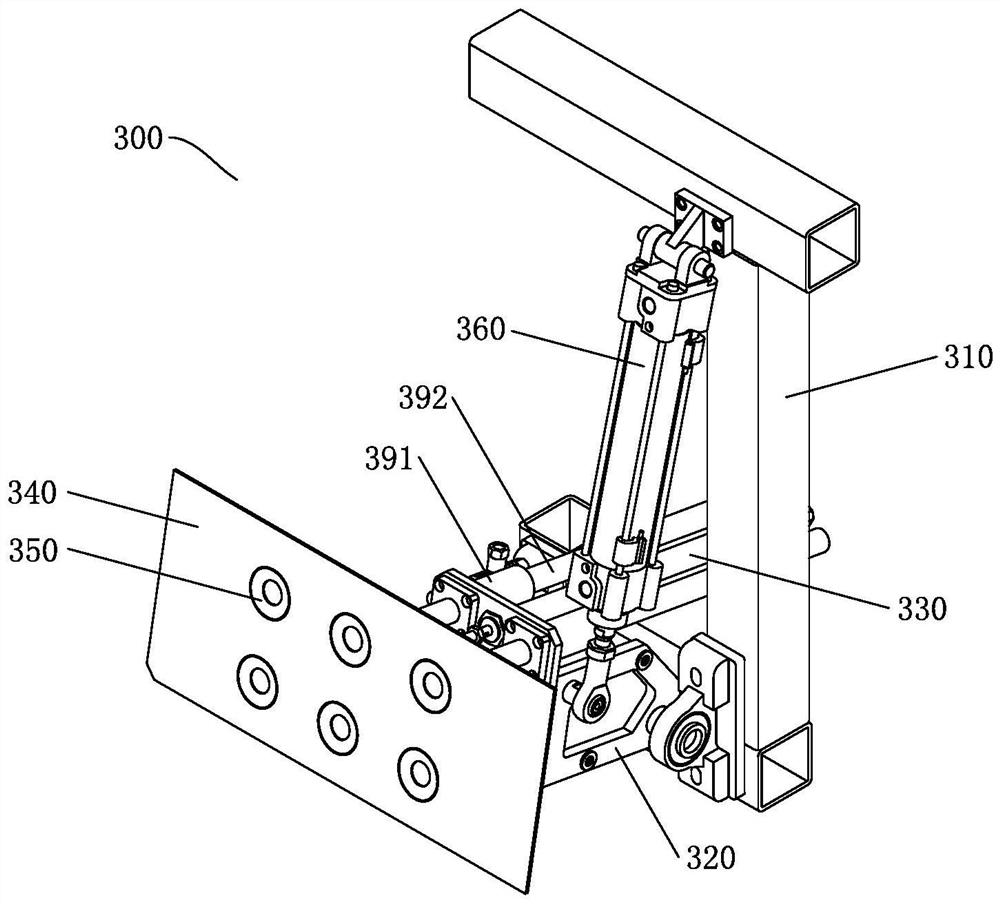

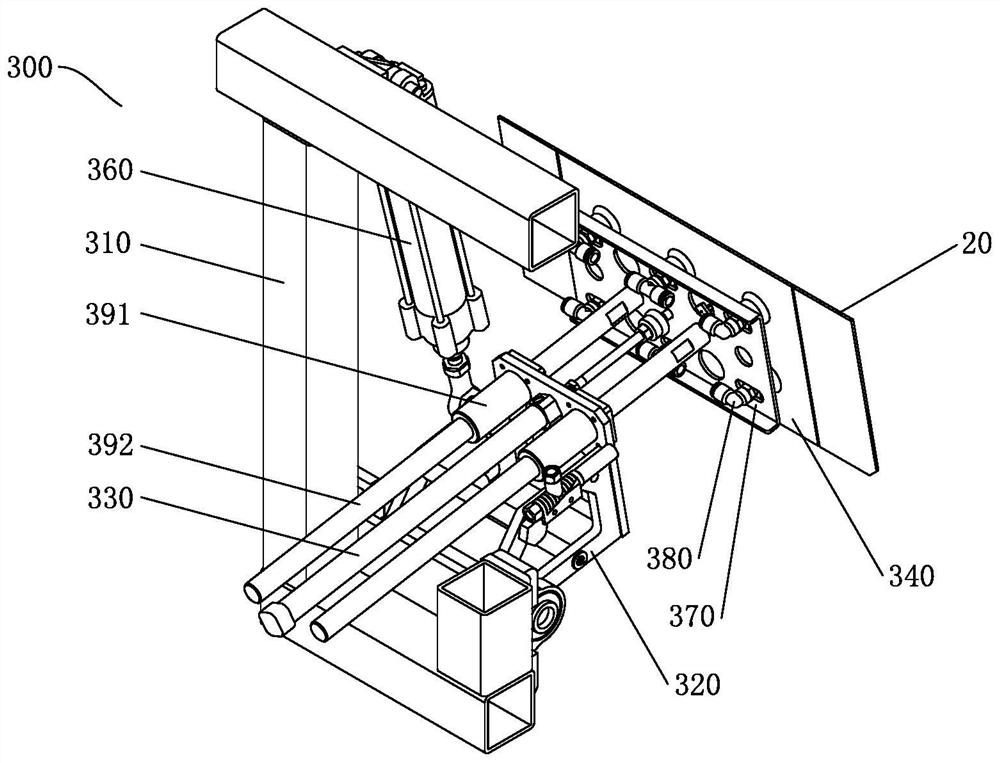

[0036] like Figure 1 to Figure 9 As shown, a separator placement device 10 provided in Embodiment 1 of the present invention includes a frame 100, a feeding mechanism 200, and a pick-and-place mechanism 300. The feeding mechanism 200 moves the separator 20 to realize the feeding of the separator 20, and the pick-and-place The mechanism 300 sucks the separator 20 and puts the separator 20 into the packing box to realize the placement of the separator 20 . The pick-and-place mechanism 300 includes a bracket 310 fixed on the frame 100, a base 320 that can swing up and down on the bracket 310, a pick-and-place cylinder 330 set on the base 320, a base plate 340 driven by the pick-and-place cylinder 330, The suction cup 350 disposed on the base plate 340 and the swing cylinder 360 that drives the base 320 to swing up and down, the base plate 340 is connected to the piston rod of the pick-and-place cylinder 330, the cylinder body of the swing cylinder 360 is hinged with the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com