Synchronous separation method for 160Gd, 161Tb and 161Dy

A synchronous separation, separation and purification technology, applied in the direction of improving process efficiency, can solve the problems of nuclide residues, low sample loading, and difficulty in large-scale Curie-level production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

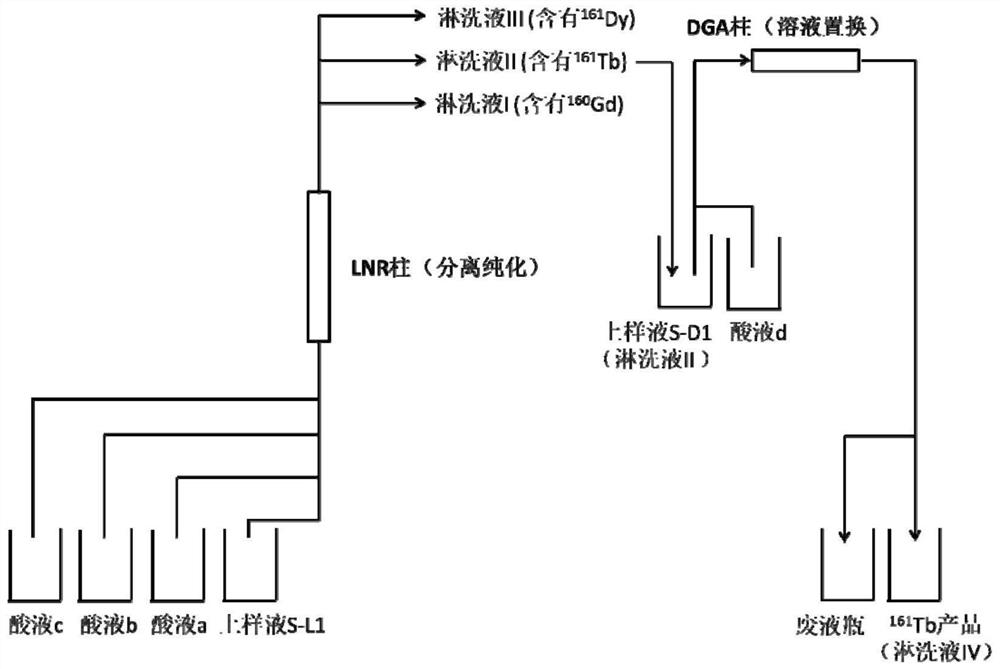

[0050] figure 1 is the use of single-stage lanthanide resin column synchronous separation 160 Gd, 161 Tb, 161 Schematic diagram of the process flow of Dy.

[0051] In this embodiment, the separation target material is 20 mg after being irradiated by the reactor 160 Gd 2 O 3 Target material (contains about 17.4mg 160 Gd, 0.0008mg 161 Tb, 0.0008mg 161 Dy), the size of the lanthanide resin separation column is that the column volume LV is 5mL, the inner diameter is 8mm, and the length is 10cm. The lanthanide resin type is commercial LN type; the size of the DGA column is that the column volume DV is 0.5mL, the inner diameter is 5mm, and the length is 2.5cm. DGA The resin model is commercial DGA-B type; the acid solutions a, b, and c used are respectively 2M nitric acid, 4M nitric acid, and 9M nitric acid; the used acid solution e is 0.9M nitric acid; the used acid solution f is 14M nitric acid;

[0052] Synchronous separation in this embodiment 160 Gd, 161 Tb, 161 The...

Embodiment 2

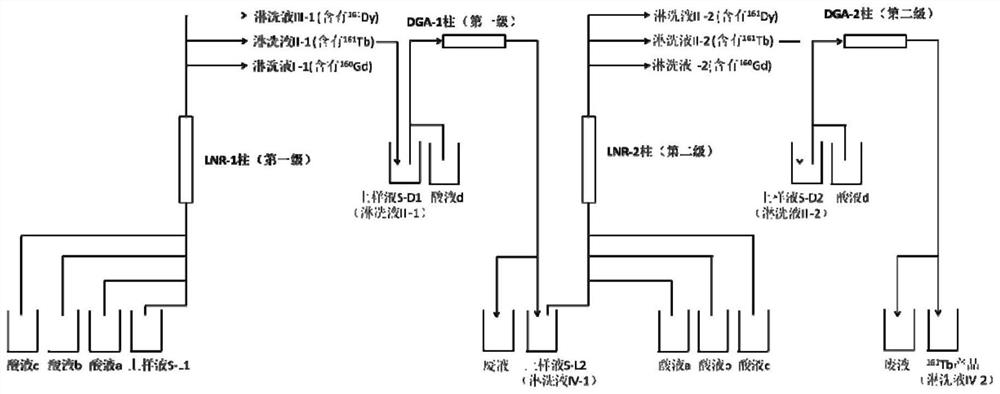

[0061] figure 2 synchronous separation using two-stage lanthanide columns 160 Gd, 161 Tb, 161 Schematic diagram of the process flow of Dy.

[0062] In this embodiment, the separation target material is 100 mg after being irradiated by the reactor 160 Gd 2 O 3 Target material (contains about 87.0mg 160 Gd, 0.004mg 161Tb, 0.004mg 161 Dy), the size of the first-stage lanthanide resin separation column is that the column volume LV is 26 mL, the inner diameter is 15 mm, and the length is 15 cm; the size of the second-stage lanthanide resin separation column is that the column volume LV is 5 mL, the inner diameter is 8 mm, and the length is 10 cm. The lanthanide resin The model is the commercial LN2 type. The size of the first-stage DGA column is that the column volume DV is 2mL, the inner diameter is 8mm, and the length is 4cm; the second-stage DGA column size is that the column volume DV is 0.5mL, the inner diameter is 5mm, and the length is 2.5cm. The DGA resin model is...

Embodiment 3

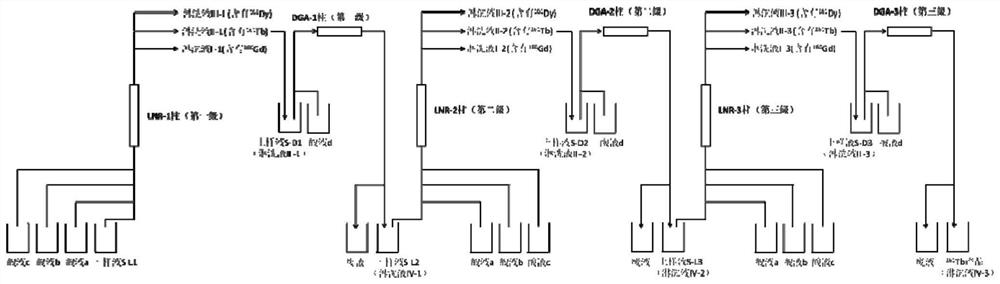

[0081] image 3 synchronous separation using a three-stage lanthanide column 160 Gd, 161 Tb, 161 Schematic diagram of the process flow of Dy. (The lanthanide resin separation column and the DGA solution replacement column used in the third stage are new chromatographic columns)

[0082] In this embodiment, the separation target material is 1000 mg after being irradiated by the reactor 160 Gd 2 O 3 Target material (contains about 869.6mg 160 Gd, 0.04mg 161 Tb, 0.04mg 161 Dy), the size of the first-stage lanthanide resin separation column is that the column volume LV is 247 mL, the inner diameter is 30 mm, and the length is 35 cm; the size of the second-stage lanthanide resin separation column is that the column volume LV is 26 mL, the inner diameter is 15 mm, and the length is 15 cm; the third stage The dimension of the lanthanide resin separation column is that the column volume LV is 5 mL, the inner diameter is 8 mm, and the length is 10 cm, and the model of the lant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com