High-purity difluorosulfonylimide preparation method

A technology of difluorosulfonimide and crude difluorosulfonimide is applied in the field of preparation of high-purity difluorosulfonimide, and can solve the residual problem of dichlorosulfonimide-fluoro-chlorosulfonimide , It is difficult to control the chloride ion impurity content, increase the complexity of the salt-forming process, etc., to achieve the effects of short treatment process, significant separation effect, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

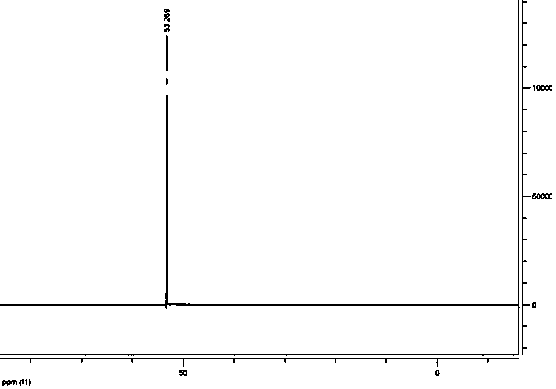

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment:

[0020] A preparation method of high-purity difluorosulfonimide, the method comprises the following steps:

[0021] The first step is to add a protic solvent equivalent to 0.1% to 10% of the mass of the crude difluorosulfonimide to the crude product of difluorosulfonimide, and react at 10°C to 120°C for 10min to 10h. During the heat preservation process Slowly introduce HF gas equivalent to 0-10% of the mass of the crude product of difluorosulfonimide.

[0022] In the second step, the difluorosulfonimide obtained in the first step is distilled to obtain a high-purity difluorosulfonimide with a chloride ion content below 20 ppm. In the second step, the distillation is vacuum distillation. According to the present invention, the difluorosulfonimide after the above-mentioned impurity removal process is subjected to vacuum distillation, and the fraction at about 100°C / 15mmHg is coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com