Aluminum-based composite material and semi-solid preparation method thereof

An aluminum-based composite material and a technology for composite materials, which are applied in the field of aluminum-based composite materials and their semi-solid preparation, can solve the problems of high cost, low production efficiency, and cumbersome solutions, and achieve low cost, high yield and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

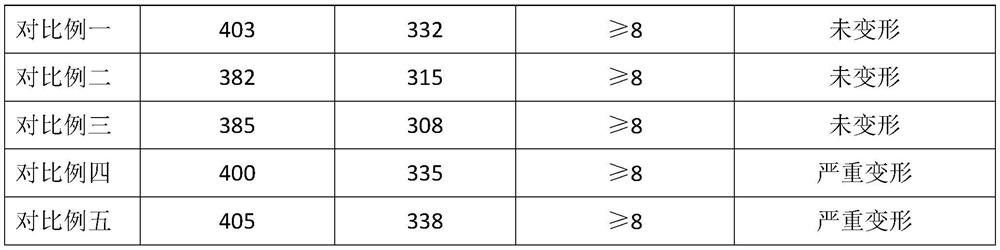

Examples

preparation example Construction

[0029] A semi-solid preparation method of an aluminum-based composite material, the steps comprising:

[0030] (1) Powder surface modification treatment: put the ceramic particle powder and ball milling ball in a ball mill, wherein the ball-to-material ratio of the ball milling ball and the ceramic particle powder is 1-2:10, and the rotation speed of the ball mill is kept at 90-120 rpm / min, the time is 5-15min, to obtain powder A;

[0031] (2) Preparation of molten alloy liquid: according to the requirements of alloy mass percentage, put Al-20Si master alloy, Al-10Mn master alloy, Al-Ti master alloy and pure aluminum ingot into the crucible at the same time, and set the heating temperature to 715~735 ℃, continue to heat the crucible, when the solid in the crucible is completely melted into a liquid, add the Mg ingot, and keep the temperature until the Mg ingot is completely melted into the alloy liquid to obtain a molten alloy liquid;

[0032](3) Semi-solid slurry preparatio...

Embodiment 1

[0038] The aluminum-based composite material of this embodiment includes, by volume percentage: 6% of ceramic particles and 94% of aluminum alloy. The ceramic particle material is boron carbide. The average size of the ceramic particles was 5 μm. The aluminum alloy is a 6-series aluminum alloy, and includes the following components by mass percentage: Si1.32%, Fe0.20%, Mn0.86%, Mg1.10%, Ti0.12%, and the rest are Al. The composite material in this embodiment is carried out according to the following steps:

[0039] (1) Powder surface modification treatment: the ceramic particle powder and the ball mill ball are placed in a ball mill, wherein the ball-to-material ratio of the ball mill ball and the ceramic particle powder is 1:10, and the rotational speed of the ball mill is kept at 90 rpm, and the time For 5min, powder A was obtained;

[0040] (2) Preparation of molten alloy liquid: According to the requirements of the mass percentage of aluminum alloy, put the Al-20Si maste...

Embodiment 2

[0045] The aluminum-based composite material of this embodiment includes, by volume percentage, 14% of ceramic particles and 86% of aluminum alloy. Wherein, the material of the ceramic particles is boron carbide. The average size of the ceramic particles was 15 μm. The aluminum alloy is a 6-series aluminum alloy, and includes the following components by mass percentage: Si1.35%, Fe0.25%, Mn0.96%, Mg1.15%, Ti0.15%, and the rest are Al. The composite material in this embodiment is carried out according to the following steps:

[0046] (1) Powder surface modification treatment: the ceramic particle powder and the ball mill ball are placed in a ball mill, wherein the ball-to-material ratio of the ball mill ball and the ceramic particle powder is 2:10, and the rotation speed of the ball mill is kept at 120 rpm, and the time For 15min, powder A was obtained;

[0047] (2) Preparation of molten alloy liquid: According to the requirements of the mass percentage of aluminum alloy, pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com