Hydraulic construction method for slip form of concrete gate pier

A construction method and concrete technology, which is applied in sea area engineering, water conservancy engineering, infrastructure engineering, etc., can solve the problems of large turnover material occupation, large material occupation, and great impact on construction costs, so as to ensure the appearance quality and round curve Sleek, less occupancy and consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

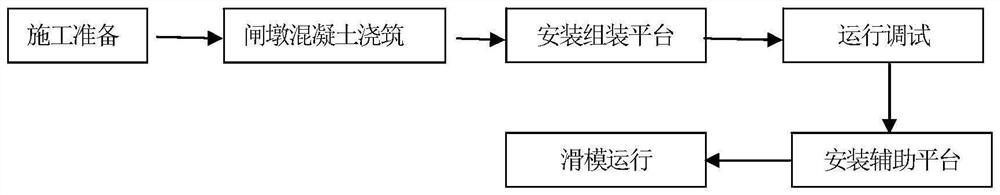

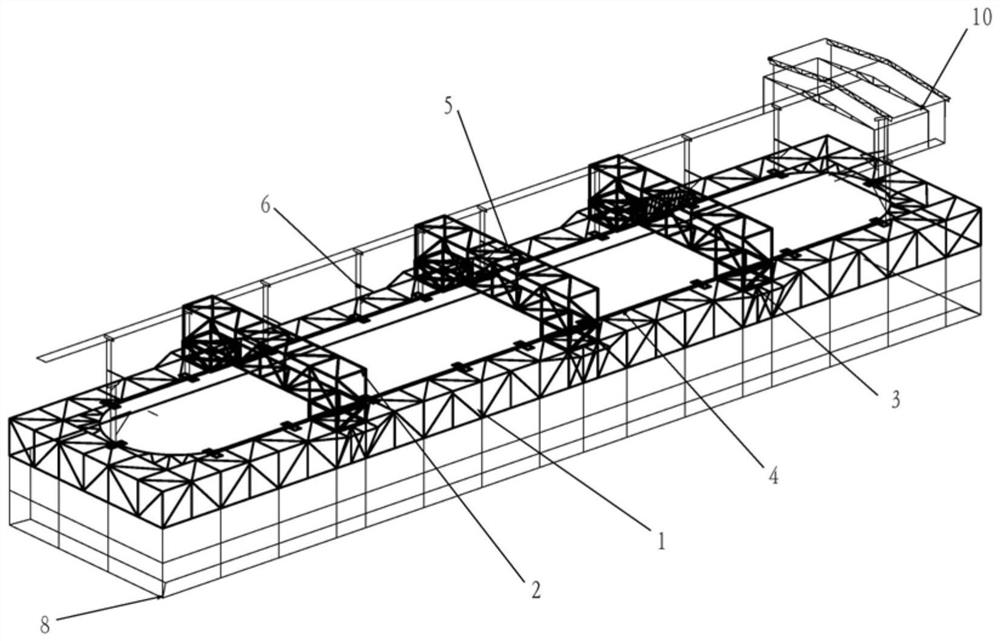

[0033] exist figure 1 In the present invention, a slip-form hydraulic construction method for concrete gate piers, comprising the following steps:

[0034] S1. First pour a part of the gate pier. After the gate pier concrete should reach a certain strength, install the assembly platform on the gate pier to check its level and verticality.

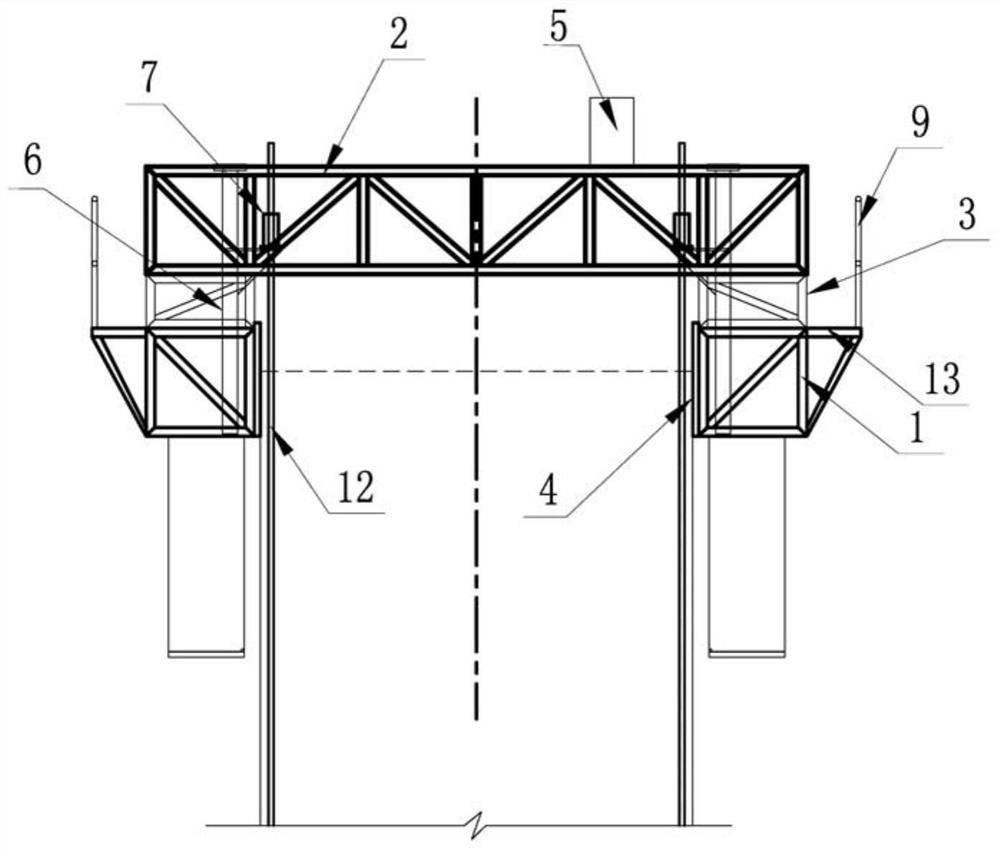

[0035] S2. Install the ring beam 1, first assemble the ring beam 1, the template 4 and the platform steel plate 13 in sections, and then hoist each section on the platform to combine, mark the position of each part on the ring beam 1, and lift it at the set position The frame 6 is fixed with the upright column of the ring beam 1, and the door slot part adopts the dismantling-free formwork. Assembly should take into account the dismantling of the segmented arrangement.

[0036] S3, install the beam support 3 and the elevated beam 2. At the same time, the overhead beam 2 divides the device into four parts, which is convenient for disassemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com