Active waterproof system for anchorage foundation enclosure structure of suspension bridge and construction method

A technology for enclosure structures and suspension bridges, which is applied in the direction of infrastructure engineering, buildings, sheet pile walls, etc., can solve problems such as poor operability, high power consumption, and easy corrosion of electricity, so as to achieve simple construction, ensure construction safety, and highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

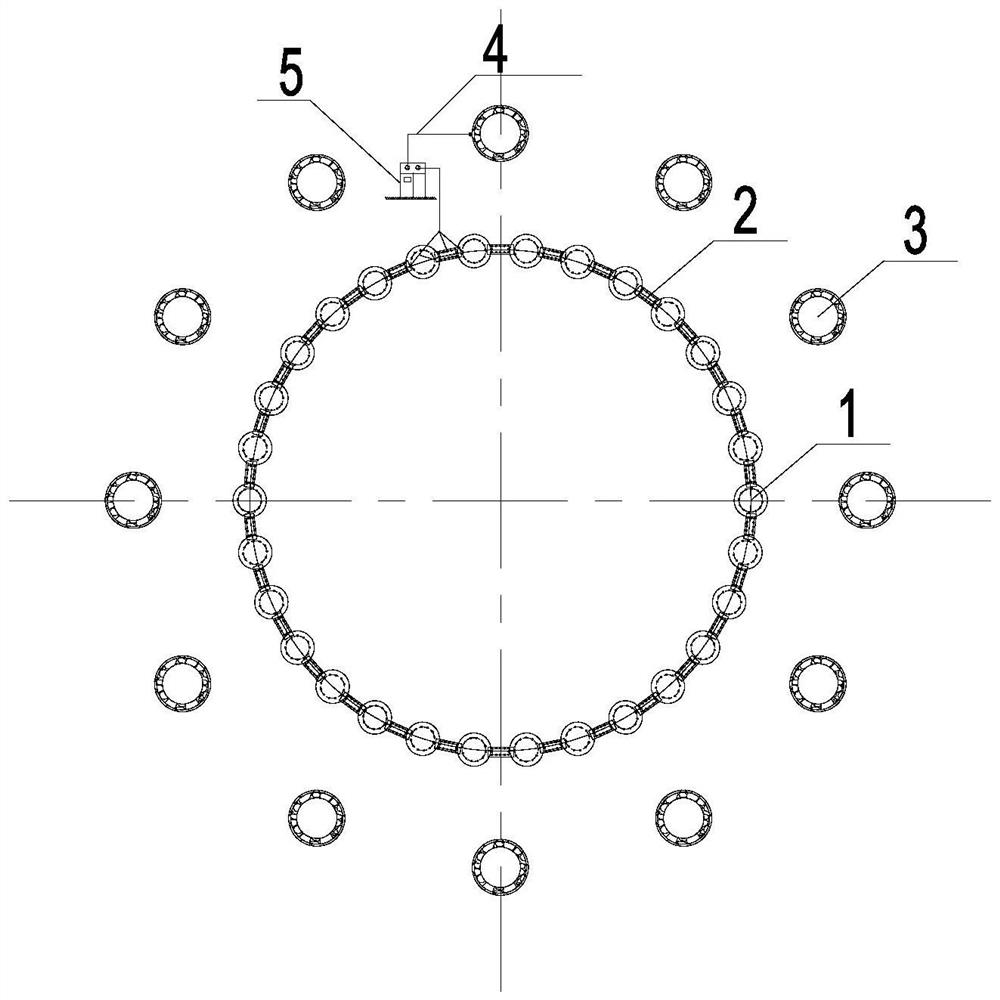

[0037] An active waterproofing system of an anchorage foundation enclosure structure of a suspension bridge is mainly composed of bored cast-in-place piles 1 , enclosure walls 2 , cathode dewatering wells 3 , wires 4 , and stabilized DC electroosmosis cabinets 5 .

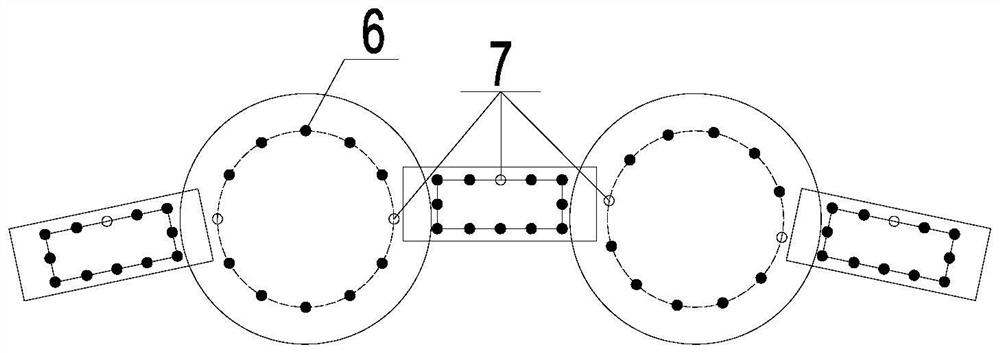

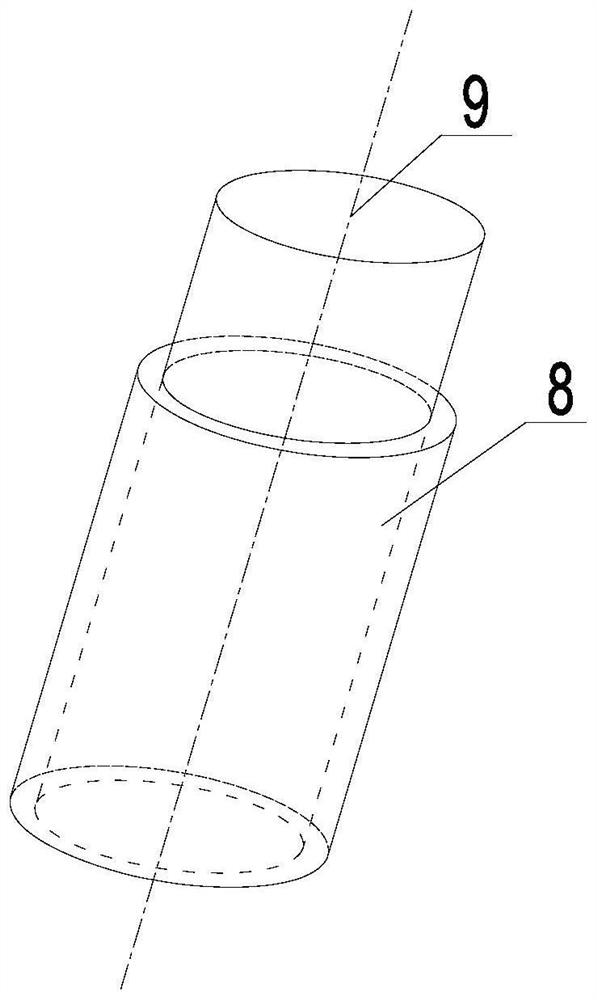

[0038] The local steel bar 6 on the described bored pile 1 and the enclosure wall 2 is replaced by the steel bar anode 7 of the coating layer, which is used as an anode for electroosmosis and anti-seepage, which can avoid anode corrosion as much as possible; when the steel bar cage is processed, the coating layer is directly The steel anode 7 is welded on the steel cage. The outer part of the clad steel anode 7 is a stainless steel cladding 8, and the inner part is an inner cladding steel bar 9.

[0039] The prior art reinforcement cages use common steel bars; 1. When using electro-osmosis active waterproofing, a single cladding steel bar is used to replace the common steel bar at the position, and direct current i...

Embodiment 2

[0044] The construction method of the active waterproofing system of the anchorage foundation envelope structure of the suspension bridge specifically includes the following steps:

[0045] Step 1: Follow figure 1 Use the marked reinforcement method and replace the ordinary reinforcement with some cladding reinforcement, process the reinforcement cage of the bored pile 1 and the retaining wall 2, and carry out the construction of the pile wall. The cathode dewatering well 3 is constructed. The dewatering wells are arranged in a 30° circumferential direction to collect the water in the rock and soil outside the foundation pit and remove it.

[0046] Step 2: Excavation of the foundation pit. During the excavation process, check the inner wall of the enclosure structure of the foundation pit to find leakage points.

[0047] Step 3: Use wire 4 and stabilized DC power supply 5 to connect the clad steel anode 7 and the cathode dewatering well 3 near the leakage point, and apply 30V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com