Safe fabricated steel structure waterproof outer wall with flat structure

A safe and prefabricated technology, applied in structural elements, building structures, walls, etc., can solve the problems of short service life, weak impact resistance of decorative covers, and no reinforcement of decorative covers and walls, and achieves service life. Long, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

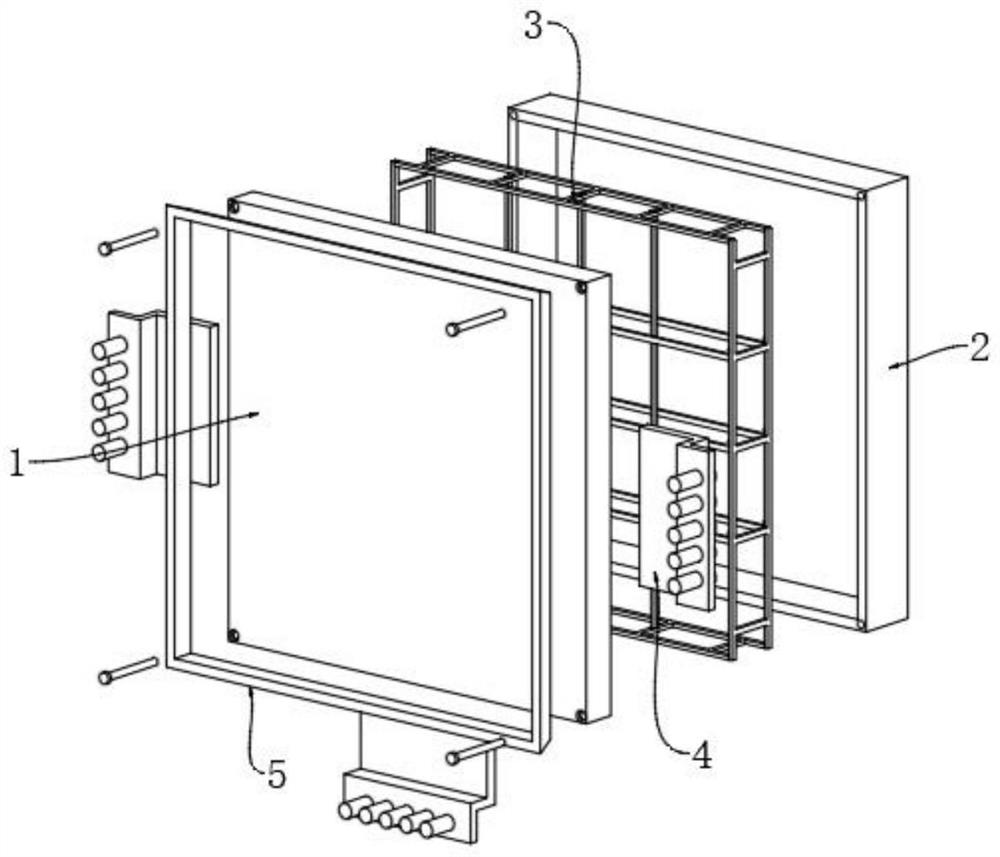

[0036] see figure 1 As shown in the figure, a flat and safe assembled steel structure waterproof exterior wall described in this embodiment includes a wall body 1 and a decorative cover 2, and the decorative cover 2 and the wall body 1 are detachably connected by bolts, which is consistent with the prior art. the difference is,

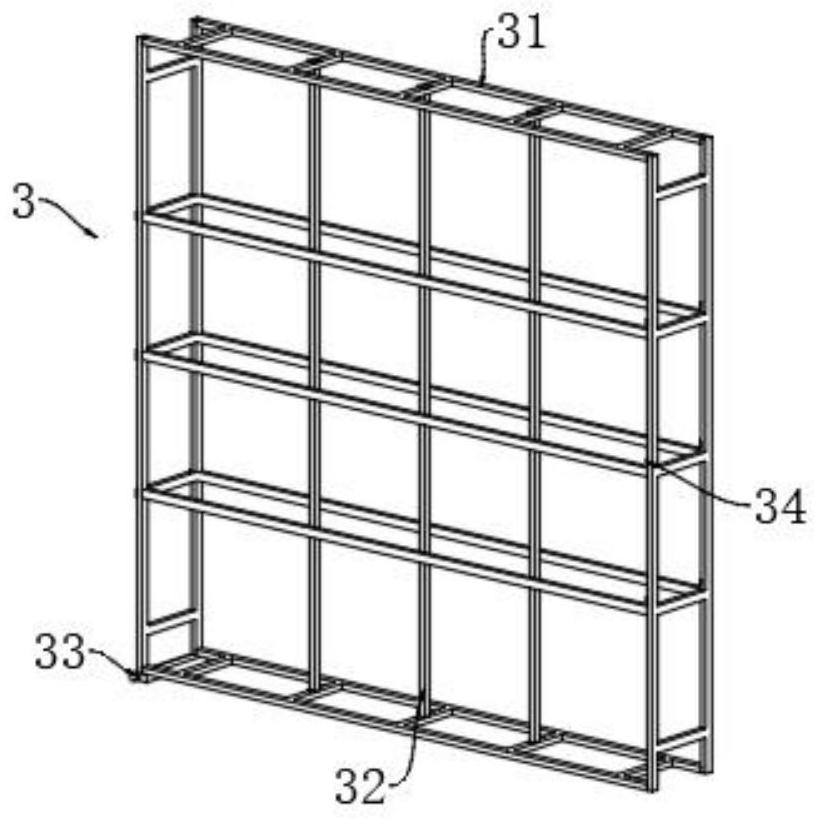

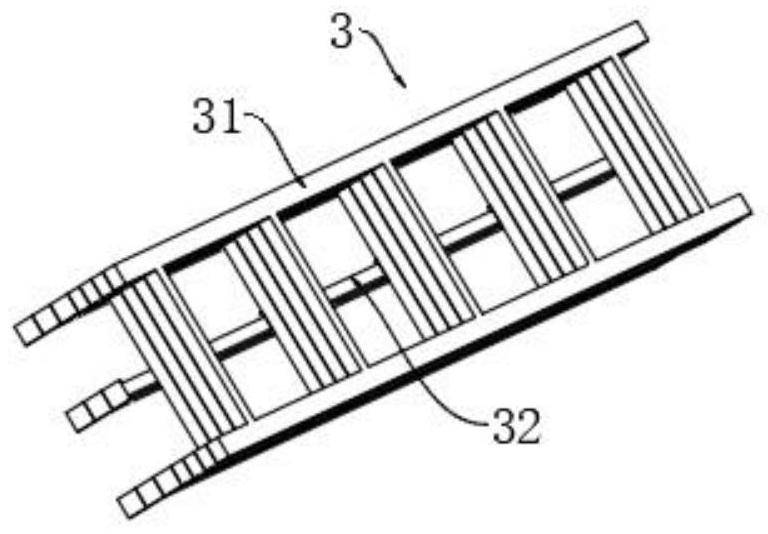

[0037] A reinforcing component 3 is also arranged between the wall body 1 and the decorative cover 2, and the reinforcing component 3 is embedded in the decorative cover 2. The reinforcing component 3 includes four steel frames 31, and between the four steel frames 31 The lock buckle 33 is detachably connected and connected;

[0038] Both sides and the bottom of the wall body 1 are provided with mounting brackets 4, and the mounting brackets 4 are fixedly welded to the wall body 1;

[0039] see Figure 4 As shown, the wall body 1 is fixed on the outside of the house through the mounting bracket 4. When in use, the wall body 1 is treated with waterp...

Embodiment 2

[0042] see figure 1 and figure 2 As shown in the figure, a flat and safe assembled steel structure waterproof exterior wall described in this embodiment includes a wall body 1 and a decorative cover 2, and the decorative cover 2 and the wall body 1 are detachably connected by bolts, which is consistent with the prior art. the difference is,

[0043] A reinforcing component 3 is also arranged between the wall body 1 and the decorative cover 2, and the reinforcing component 3 is embedded in the decorative cover 2. The reinforcing component 3 includes four steel frames 31, and between the four steel frames 31 The lock buckle 33 is detachably connected and connected;

[0044] Both sides and the bottom of the wall body 1 are provided with mounting brackets 4, and the mounting brackets 4 are fixedly welded to the wall body 1;

[0045] see Figure 4 As shown, the wall body 1 is fixed on the outside of the house through the mounting bracket 4. When in use, the wall body 1 is trea...

Embodiment 3

[0053] see figure 1 and figure 2 As shown in the figure, a flat and safe assembled steel structure waterproof exterior wall described in this embodiment includes a wall body 1 and a decorative cover 2, and the decorative cover 2 and the wall body 1 are detachably connected by bolts, which is consistent with the prior art. the difference is,

[0054] A reinforcing component 3 is also arranged between the wall body 1 and the decorative cover 2, and the reinforcing component 3 is embedded in the decorative cover 2. The reinforcing component 3 includes four steel frames 31, and between the four steel frames 31 The lock buckle 33 is detachably connected and connected;

[0055] Both sides and the bottom of the wall body 1 are provided with mounting brackets 4, and the mounting brackets 4 are fixedly welded to the wall body 1;

[0056] see Figure 4 As shown, the wall body 1 is fixed on the outside of the house through the mounting bracket 4. When in use, the wall body 1 is trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com