Pneumatic automatic temperature adjusting thermostat and adjusting method thereof

A thermostat, automatic technology, applied in the direction of engine components, engine cooling, machine/engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

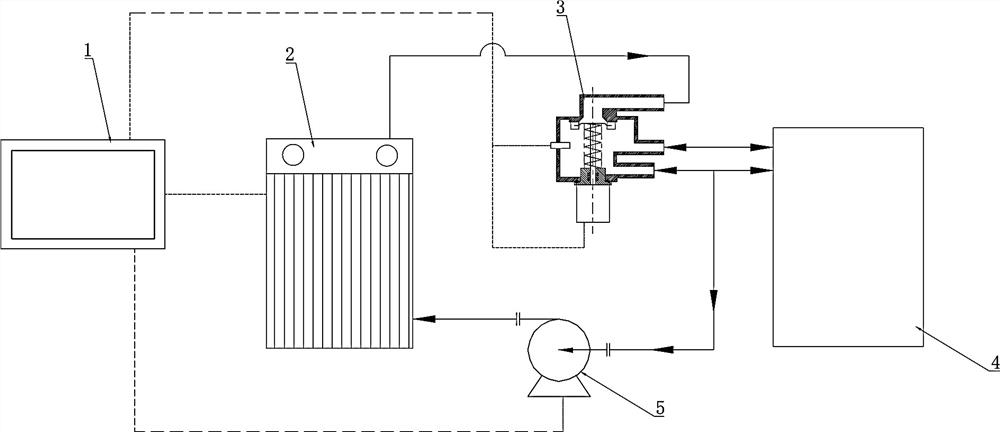

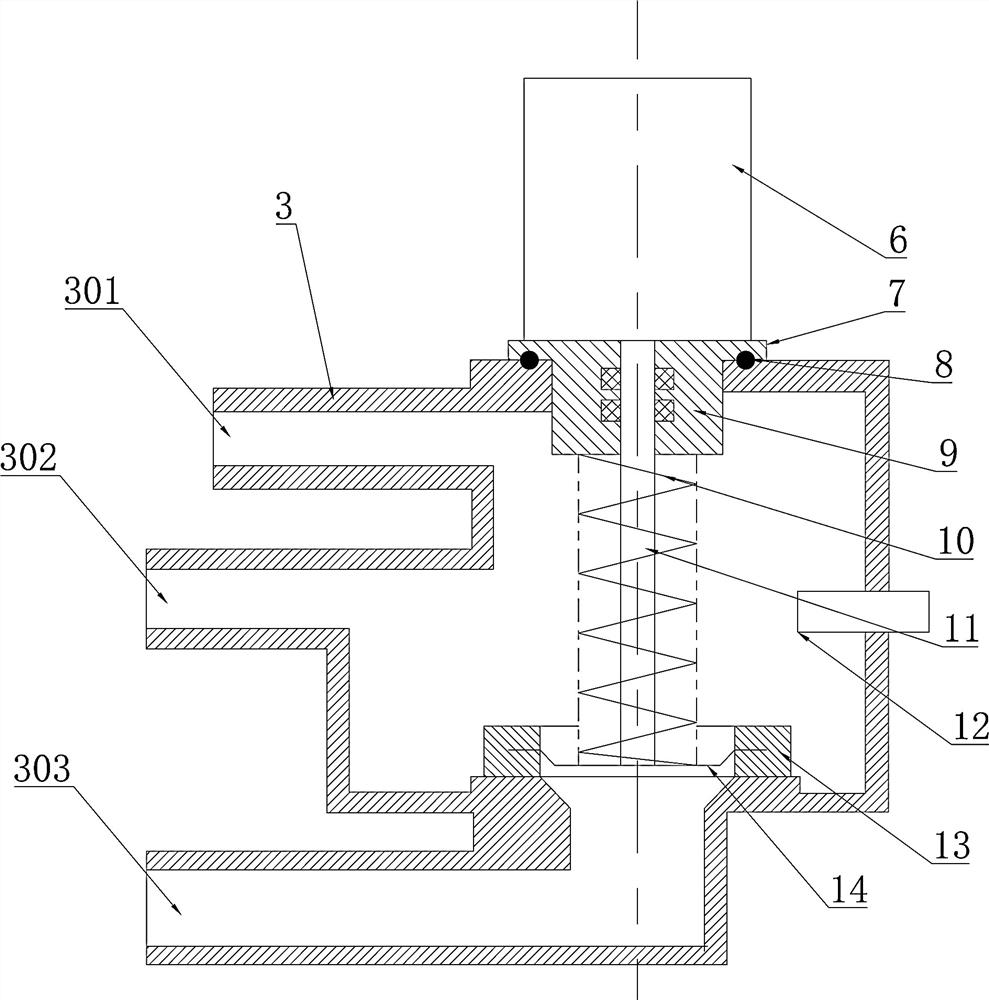

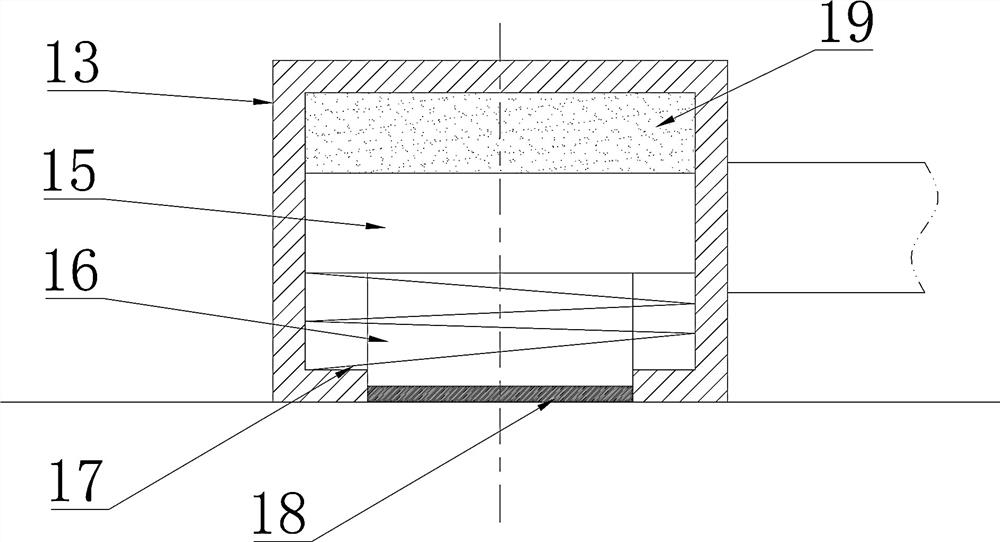

[0032] like Figures 1~5 As shown, a pneumatic automatic thermostat, the cavity of the thermostat 3 is provided with three connection ports, including a first connection port 301, a second connection port 302 and a third connection port 303, the thermostat 3 cavity There is a pneumatic element 6 on the body, the end of the piston rod 11 of the pneumatic element 6 is provided with a sealing pressing ring 13, the third connecting port 303 and the connecting port of the thermostat 3 cavity are arranged coaxially with the piston rod 11, and the sealing and pressing The ring 13 abuts against the third connection port 303 , so that the third connection port 303 is connected with the first connection port 301 and the second connection port 302 , and the temperature sensor 12 is also provided in the cavity of the thermostat 3 . When the engine 4 is just pneumatic, the water temperature decreases, the temperature sensor 12 is lower than the set value X, and the changed value is transmi...

Embodiment 2

[0043] Further illustrate in conjunction with embodiment 1, as Figure 1-5 In the structure shown, when the engine 4 is just pneumatic, the water temperature decreases, the temperature sensor 12 is lower than the set value X, and the changed value is transmitted to the controller 1, and the controller 1 controls the pneumatic element 6 to extend the piston rod 11, and the piston rod 11 The sealing plate 14 at the end is tightly pressed against the third connection port 303 of the large circulation, at this time, the first connection port 301 and the outlet of the second connection port 302 are connected, and the cooling water is in the small circulation.

[0044] After the engine 4 runs for a period of time, the water temperature is raised, the temperature sensor 12 should have a temperature higher than the set value X, and transmit the water temperature to the controller 1 in real time. The controller 1 controls the pneumatic element 6 to shrink the piston rod 11, and will Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com