Propellant vertical storage and turnover performance evaluation method

A propellant and performance technology, applied in the field of solid propellants, can solve problems such as changes in physical and chemical properties and ballistic performance, storage, transportation and use damage of solid rocket motors, and systematic research on the mechanical response of unseen propellant grains. Achieve the effect of improving research and development efficiency and solving related engineering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0044] The invention provides a method for evaluating the vertical storage and inversion performance of propellants, such as figure 1 The specific implementation steps are as follows:

[0045] Step 1, perform a uniaxial tensile test and a conventional temperature test on the initial plan of a certain HTPB propellant grain; the initial plan includes the propellant material to be evaluated and the grain combustion chamber structure, and the combustion chamber structure includes the grain geometry Profile, charge length, grain length-diameter ratio and grain number;

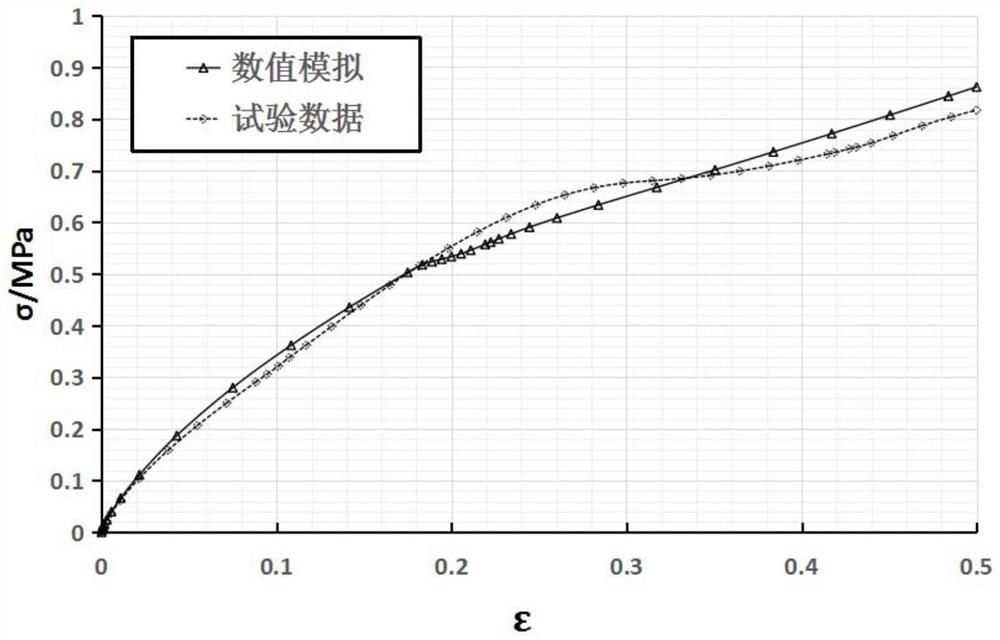

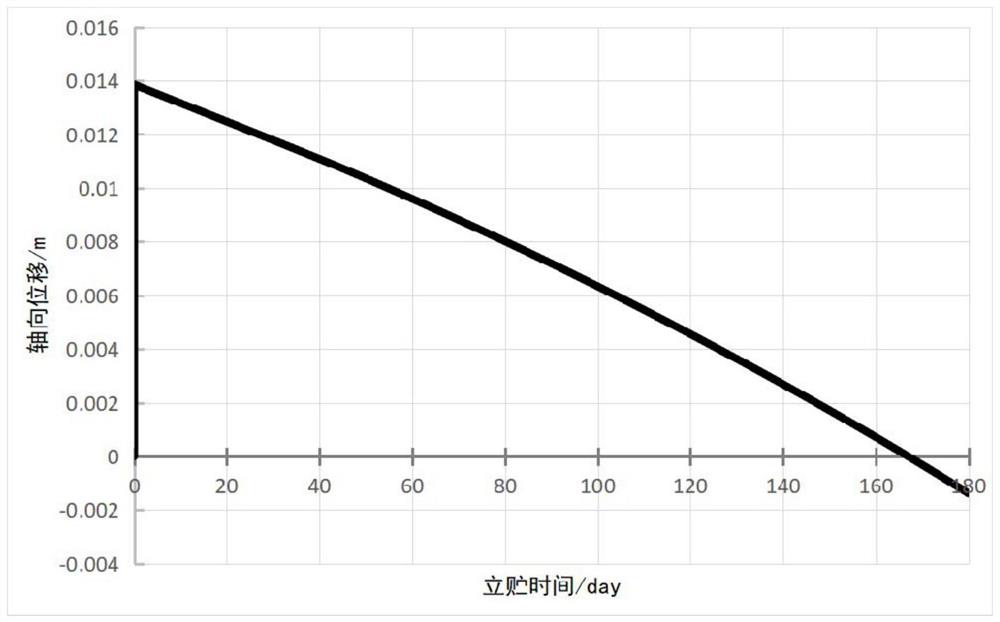

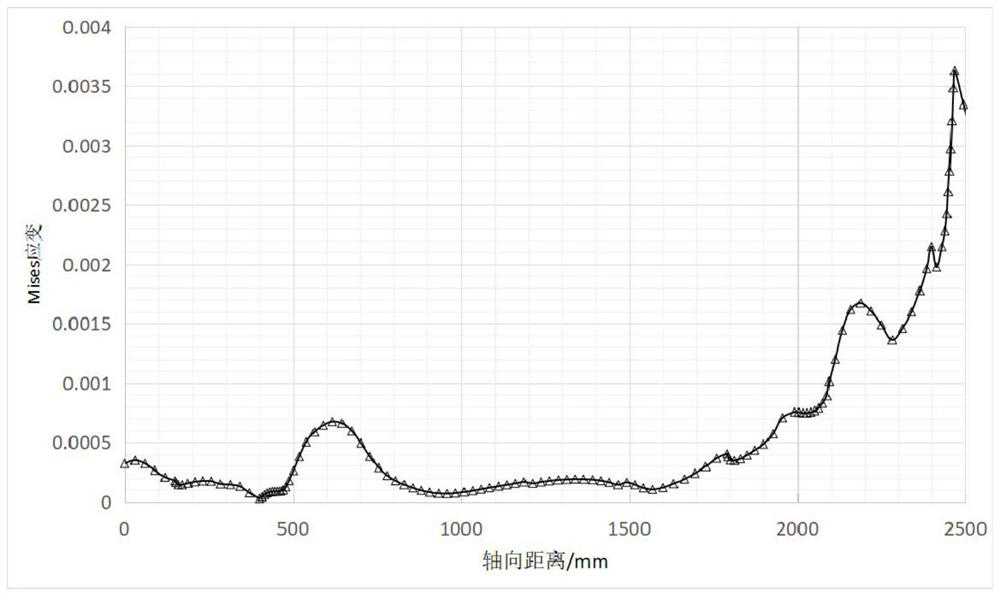

[0046]In step 2, the stress-strain curve of the propellant to be evaluated is obtained through the uniaxial tensile test described in step 1, and the main curve of relaxation modulus and time-temperature translation factor of the propellant to be evaluated are obtained through the stress-str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com