Raw material blending and stirring equipment for white spirit production

A technology for mixing equipment and raw materials, which is used in mixer accessories, mixers, dissolving and other directions, can solve problems such as poor device stability, low device use efficiency, and inconvenient cleaning, and achieve the effect of improving stability and reducing vibration amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

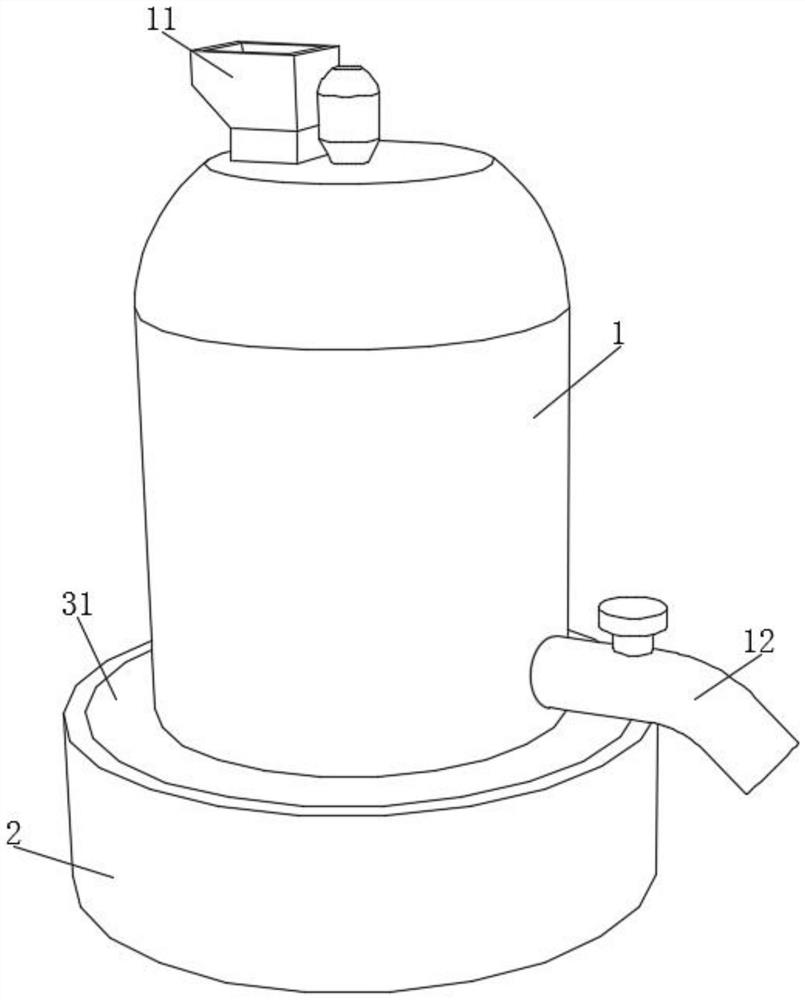

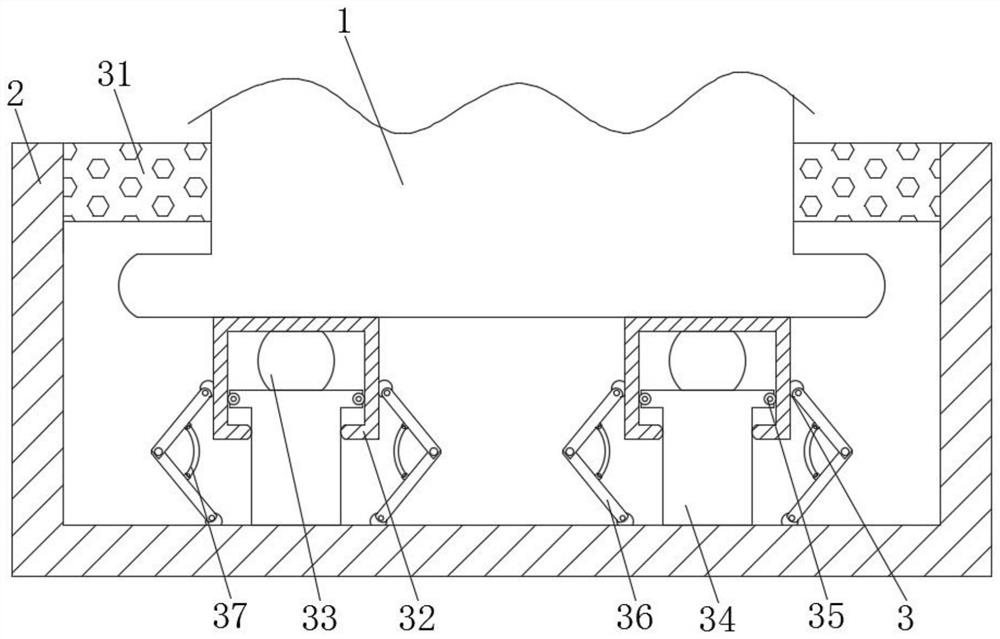

[0032] like Figure 1-6As shown, the present invention provides a raw material blending and stirring device for liquor production, comprising a stirring device main body 1 and a base 2, the base 2 is arranged at the bottom of the stirring device main body 1, and a feeding hopper is fixedly connected to the upper surface of the stirring device main body 1 11. A discharge pipe 12 is fixedly connected to the outer surface of the main body 1 of the stirring device, a stable shock absorbing mechanism 3 is arranged between the main body 1 of the stirring device and the base 2, and a scraping mechanism 4 is arranged inside the main body 1 of the stirring device to stabilize The shock mechanism 3 includes a lateral soft shock-absorbing plate 31, one side of the lateral soft shock-absorbing plate 31 is fixedly connected with the inner wall of the base 2, and the inner wall of the lateral soft shock-absorbing plate 31 is movably connected with the outer surface of the main body 1 of the ...

Embodiment 2

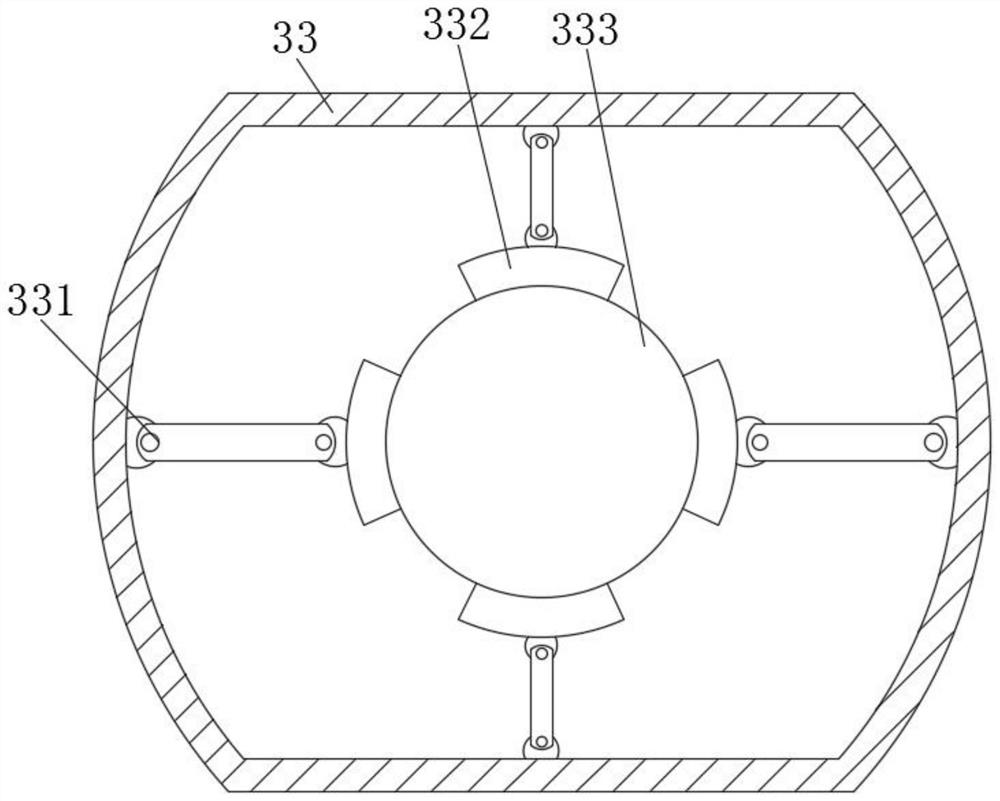

[0035] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a connecting rod 331 is movably connected to the inner wall of the elastic sleeve plate 33, and one end of the connecting rod 331 is movably connected with an abutting plate 332, which abuts against An elastic spherical shell 333 is fixedly connected to the outer surface of the connecting plate 332, and a pulling rod 3331 is movably connected to the inner wall of the elastic spherical shell 333. Both ends are fixedly connected with the inner wall of the elastic spherical shell 333 , and the outer surface of the soft stabilizer bar 3332 is fixedly connected with a tension spring 3333 .

[0036] In this embodiment, when the elastic sleeve plate 33 is compressed and elastically deformed, the abutting plate 332 is pushed by the action of the connecting rod 331, so that the elastic spherical shell 333 is stretched and compressed, and elastically deformed....

Embodiment 3

[0038] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a motor is fixedly connected to the upper surface of the main body 1 of the stirring device, and the output shaft of the motor is fixedly connected to one end of the rotating rod 41, and the rotating rod 41 A horizontal stirring rod 42 is fixedly connected on the outer surface of the horizontal stirring rod 42, a vertical stirring rod 43 is fixedly connected on the outer surface of the horizontal stirring rod 42, and the outer surface of the soft scraper 44 is fixedly connected with the outer surface of one end of the horizontal stirring rod 42. The assembly 49 is arranged on the inner side of the soft scraper 44, one end of the telescopic rod 45 is movably connected with the outer surface of the rotating rod 41, the outer surface of the counterweight impact ball 46 is fixedly connected with the other end of the telescopic rod 45, and one end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com