Production method of hot-rolled wire rod with diameter of 4.5 mm for drawing

A technology of hot-rolled wire rod and production method, applied in the direction of metal rolling, manufacturing calculation system, etc., which can solve the problems of many faults, low output, and low enthusiasm for Φ4.5mm hot-rolled wire rod, so as to increase production and reduce faults , saving annealing cost and drawing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to specific embodiments.

[0016] The purpose of this application is to realize the production of hot-rolled wire rods with a diameter of 4.5 mm.

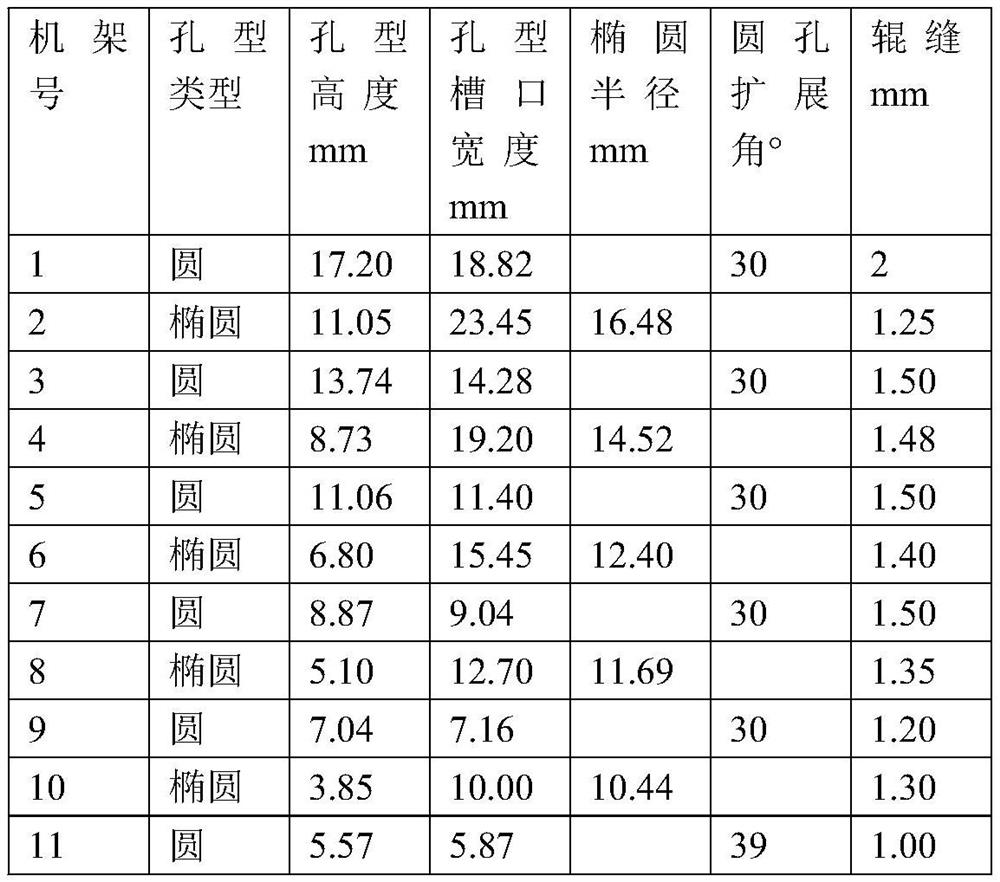

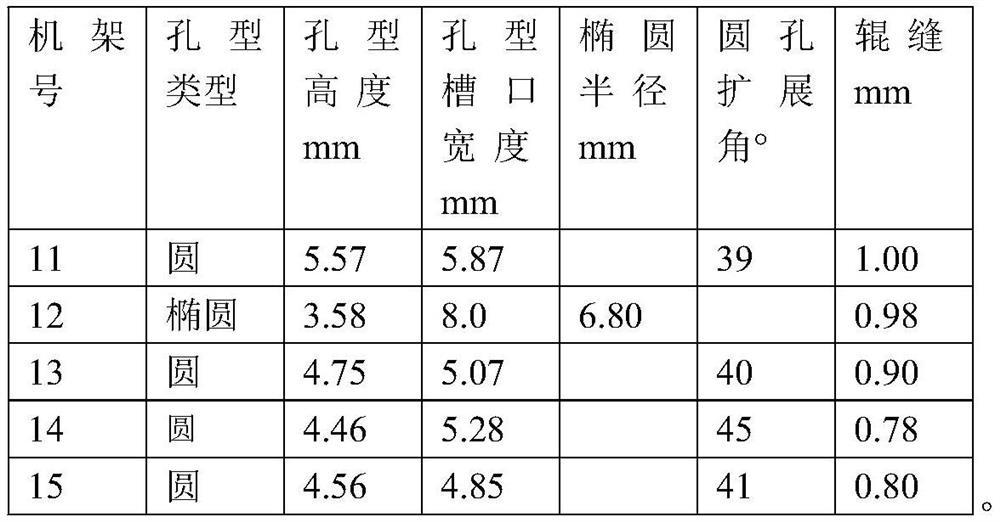

[0017] By optimizing the pass design of Φ4.5mm hot-rolled wire rod. To reduce failures and increase production. The system uses 10 finishing mills and 4 sizing and reducing mills to complete hot rolling.

[0018] The original production of Φ4.5mm hot-rolled wire rod, the finish rolling inlet is Φ18.55mm, the finish rolling outlet is Φ6.08mm, the fixed and reduced diameter size is 3.28*8.25-Φ4.87-4.51*4.96-Φ4.56, and the elongation is 1.241 / 1.256 / 1.079 / 1.057. With this pass system, there are many production failures.

[0019] Optimize the pass design of Φ4.5mm hot-rolled wire rod, adjust the finish rolling inlet from Φ18.55mm to Φ17.2mm, and adjust the finish rolling outlet size from Φ6.08mm to Φ5.5mm.

[0020] The corresponding rack numbers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com