Device and method for rapidly and efficiently screening uniform solder balls

A uniform and high-efficiency technology, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of long ball forming interval, affecting ball making efficiency, increasing solder ball preparation process, etc., to avoid secondary screening and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

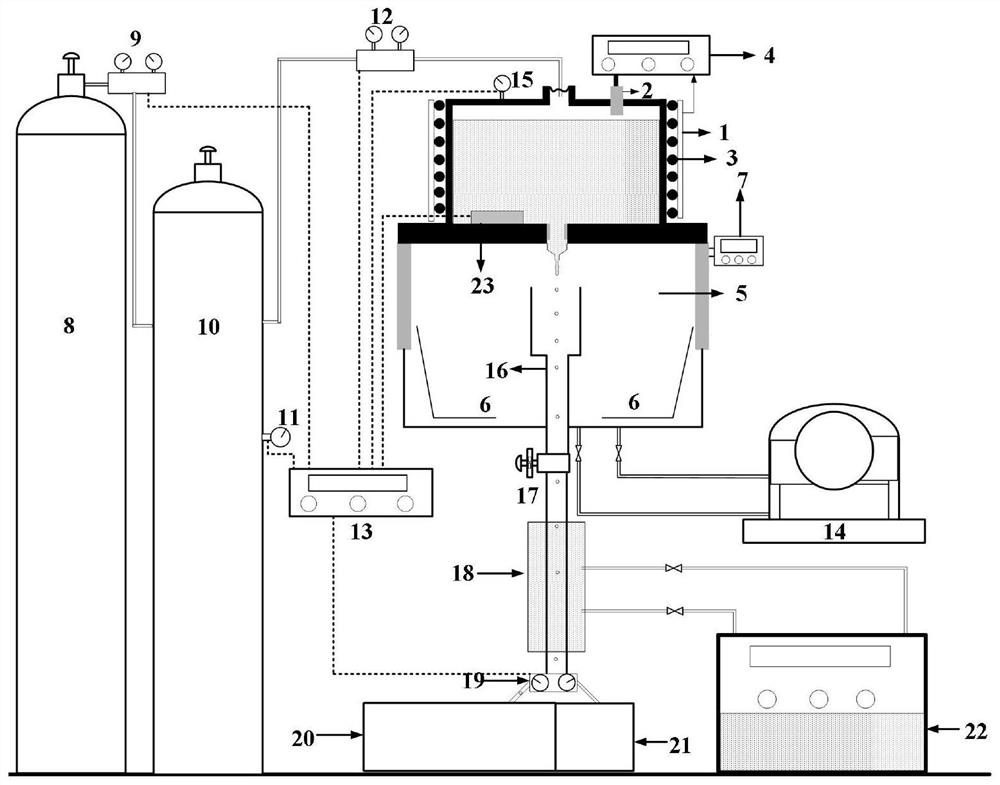

[0027] like figure 1 As shown, a device for quickly and efficiently screening uniform solder balls includes a uniform metal droplet preparation device 1 and a rapid cooling pipe 16 .

[0028] Both sides of the uniform metal droplet preparation device 1 are provided with melting heating coils 2, the uniform metal droplet preparation device 1 is provided with a temperature sensor 3, and the melting heating coil 2 and the temperature sensor 3 are connected with the intelligent PID temperature control. Instrument 4 is electrically connected.

[0029] A spherical cavity 5 is provided at the lower end of the uniform metal droplet preparation device 1 , and observation windows 6 are provided on both sides of the spherical cavity 5 .

[0030] The nozzle of the uniform metal droplet preparation device 1 extends into the spherical cavity 5, and the upper end of the rapid cooling pipe 16 extends into the spherical cavity 5 and cooperates with the nozzle. The rapid cooling pipe 16 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com