A kind of multi-layer rice rubbing machine

A technology of rice machine and embryo retention, which is applied in the direction of grain germ removal, grain processing, grain pod removal, etc., which can solve the problems of impurity discharge and low rice milling efficiency, and improve the efficiency of disassembly and replacement, improve production efficiency, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

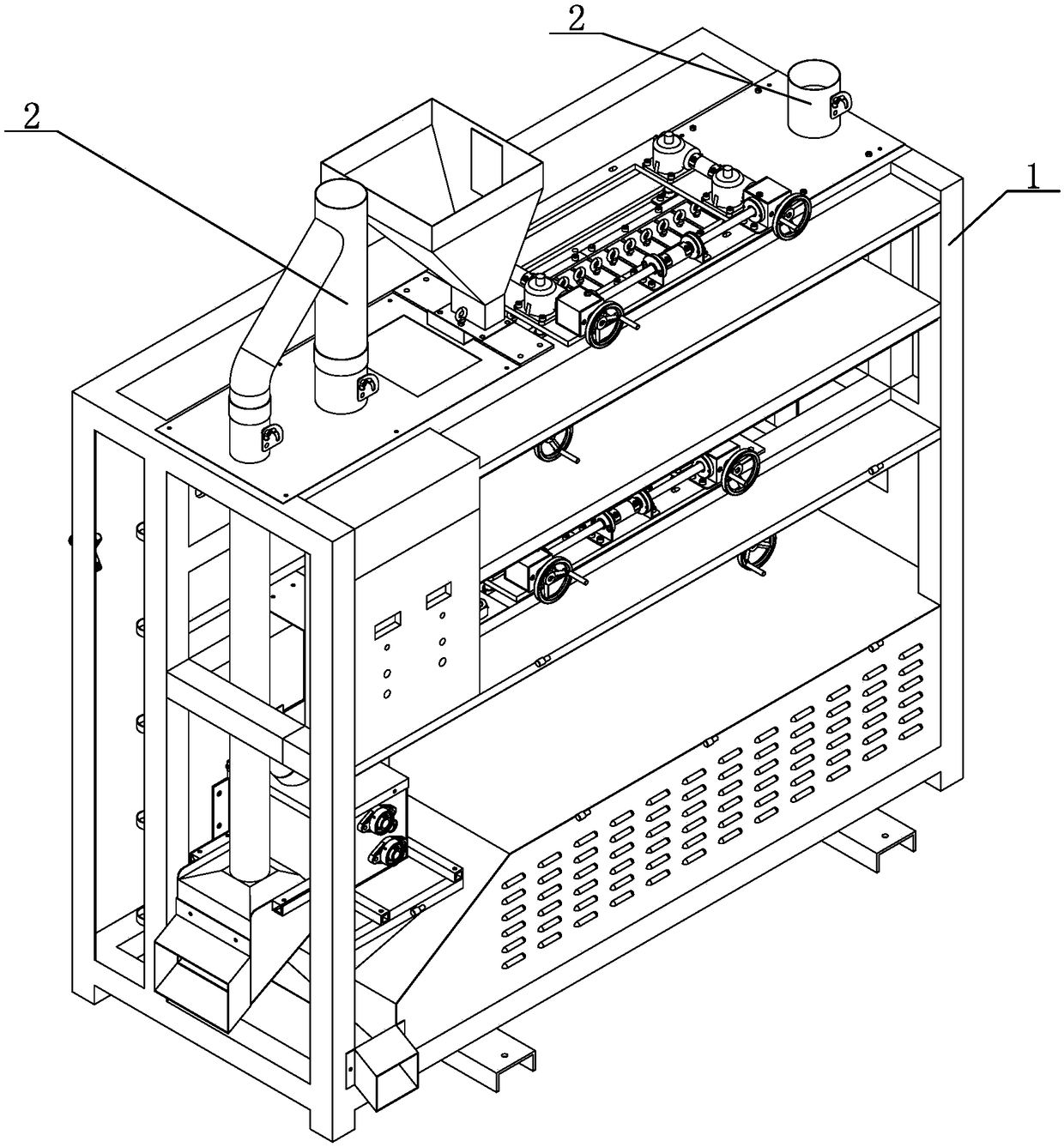

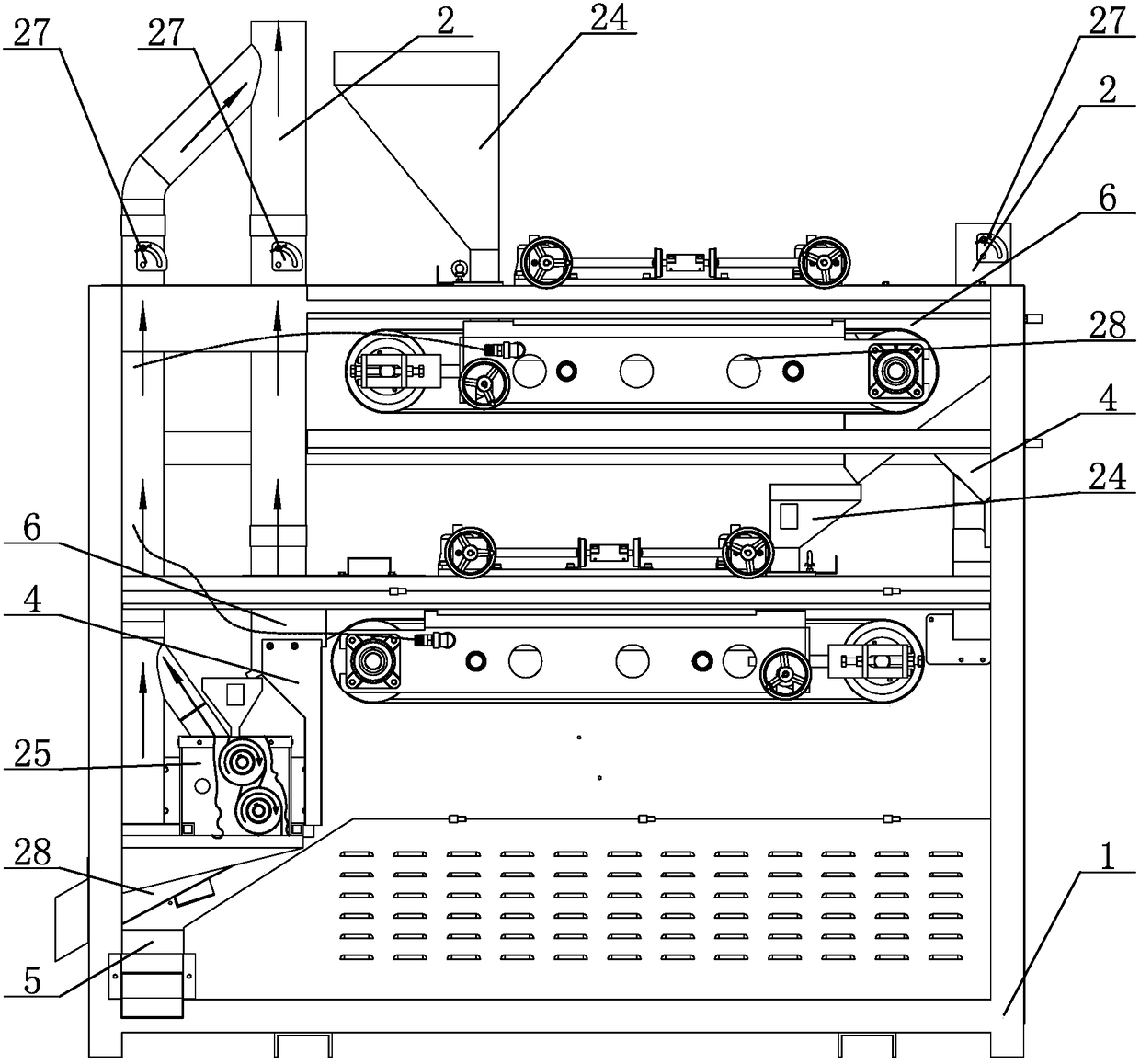

[0007] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment mode, a kind of multi-layer germination rice rubbing machine described in this embodiment mode includes frame 1, impurity pool 5, multiple rice rubbing mechanisms, multiple negative pressure air ducts 2, multiple miscellaneous conduits 3, multiple A miscellaneous bucket 4 and a plurality of driving motors 23, a plurality of said rice rubbing mechanisms are installed on the frame 1 from top to bottom in turn, and a negative pressure air blower is respectively arranged in the discharge hopper 6 of each said rice rubbing mechanism Pipe 2, miscellaneous discharge bucket 4 are arranged on the below of the hopper 6 bottom screen of described rice rubbing mechanism, each miscellaneous discharge bucket 4 communicates with impurity pool 5 through a miscellaneous conduit 3 respectively, and a plurality of drive motors 23 are installed on At the bottom of the frame 1, each drive motor 23 drive...

specific Embodiment approach 2

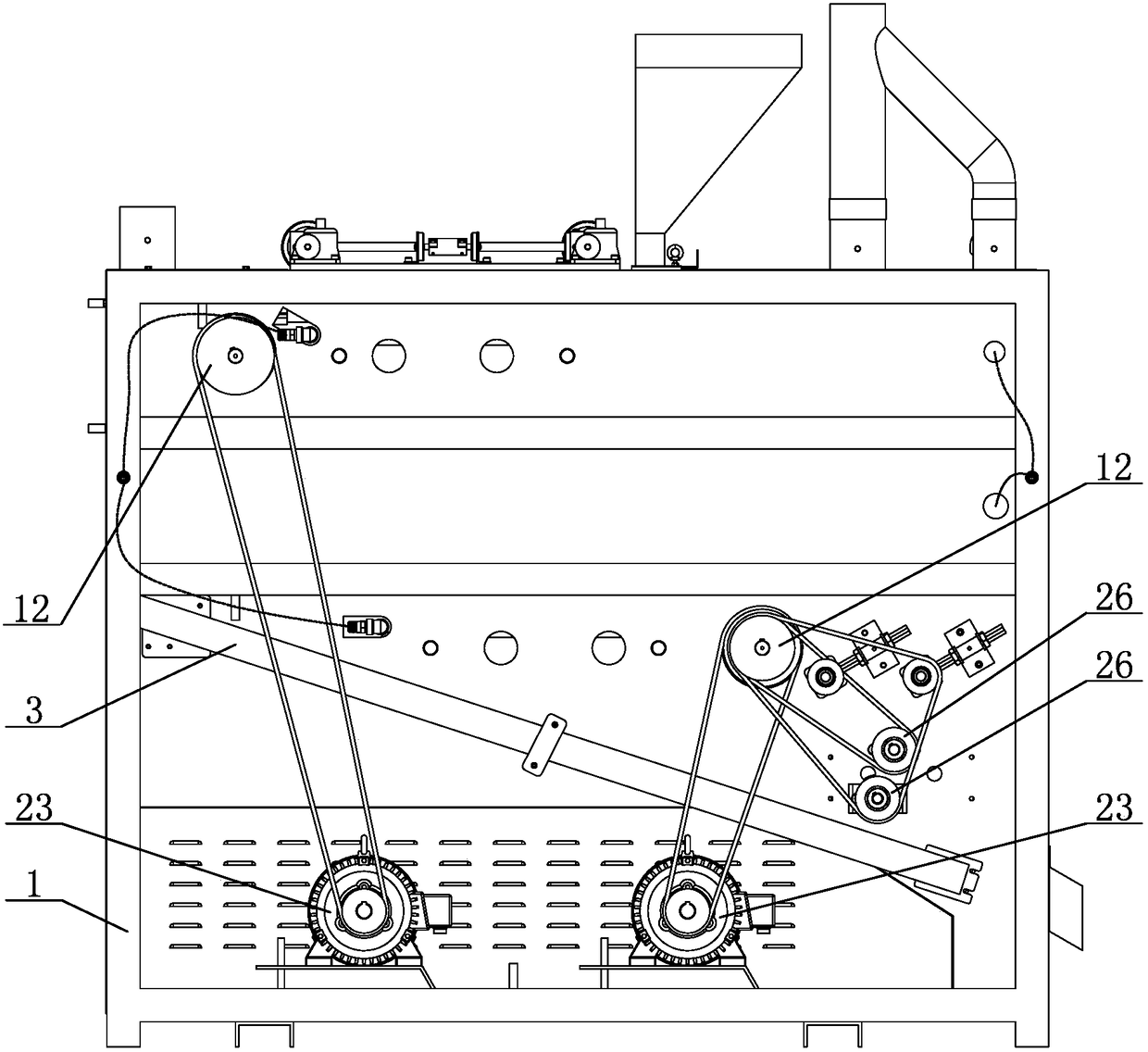

[0011] Specific implementation mode two: combination Figure 4 to Figure 9 and Figure 17 Describe this embodiment, each described rice rubbing mechanism of a kind of multi-layer germination rubbing machine described in this embodiment includes rice milling belt 7, rice rubbing knife assembly 8, belt lower supporting plate 9, rice rubbing room plate frame 10. Combined frame 11 of rice grinding belt, driving wheel 12 and multiple fixed shafts 13 with resistance. The combined frame 11 of rice grinding belt is installed on the frame 1 through multiple fixed shafts 13 of belt groups. The rice grinding belt 7 is set on the On the driving pulley 11-1 and the driven pulley 11-2 of the band combination frame 11, the belt lower supporting plate 9 is arranged between the driving pulley 11-1 and the driven pulley 11-2, and the rice rubbing knife assembly 8 is installed on On the rice rubbing room plate frame 10, and the rice rubbing knife assembly 8 is positioned at the top of the rice ...

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 4 to Figure 9 Describe this embodiment, the rice rubbing knife assembly 8 of a kind of multi-layer germination rice rubbing machine described in this embodiment is made up of frame and a plurality of rice rubbing knife units, and a plurality of described rice rubbing knife units are arranged side by side on the described frame Each of the rice rubbing knife units includes a knife holder 8-1 and a plurality of rice rubbing knife blocks 8-2, and a plurality of rice rubbing knife blocks 8-2 are arranged in a matrix, and each rice rubbing knife block 8-2 The upper ends of 2 are all connected with knife rest 8-1.

[0015] The lower surface of the knife rest 8-1 is provided with a plurality of slots 8-1-1 side by side along the length direction, and the upper end of the rice rubbing knife block 8-2 is provided with an inserting block 8-1 matched with the slot 8-1-1. 2-1, the insert block 8-2-1 is inserted in the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com