Contact type workpiece wired measuring head for numerical control milling machine

A CNC milling machine, contact technology, applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of not being able to use non-contact probes, detection result errors, and affecting measurement results, etc., to improve measurement The effect of the precision and accuracy of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

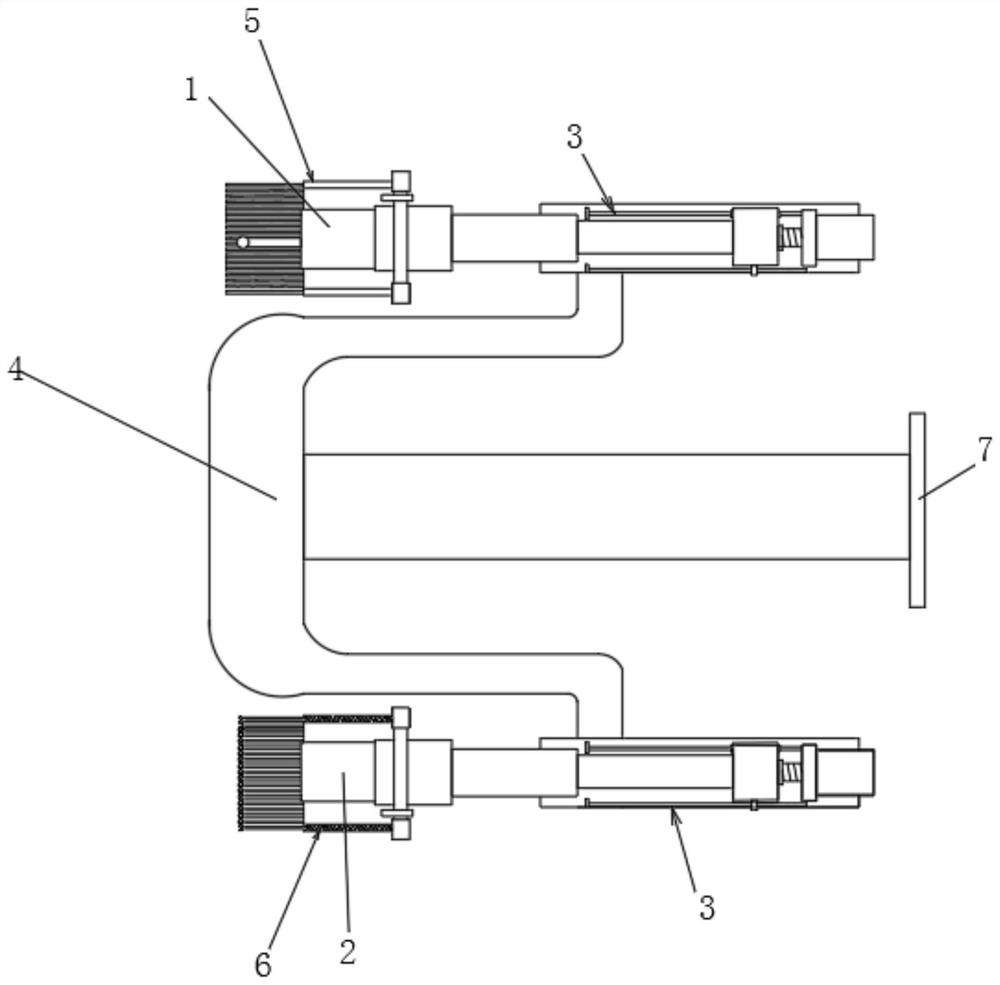

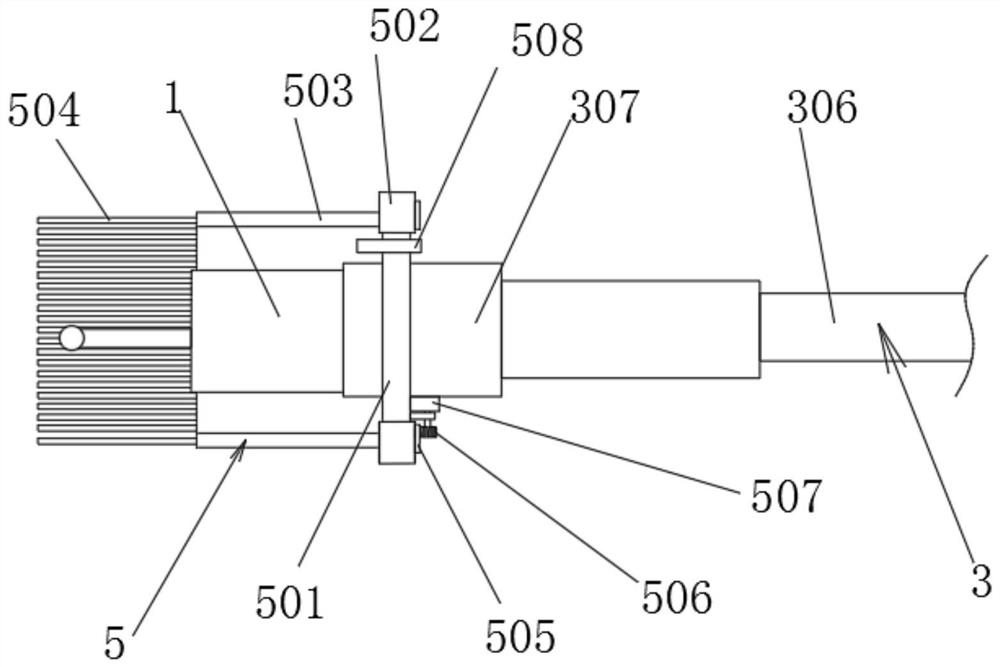

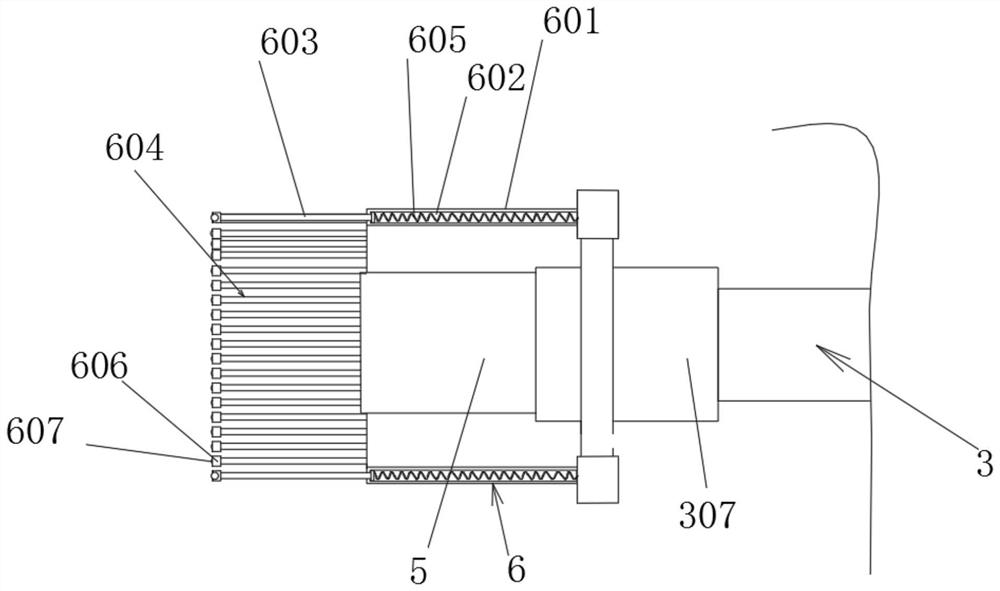

[0027] Example: as Figure 1-7 As shown in the figure, a contact type workpiece wire probe for a CNC milling machine of the present invention includes a non-contact type probe 1 and a contact type probe 2, and also includes a positioning base 4. The non-contact type probe 1 and the contact type probe 2 pass through the The telescopic storage mechanism 3 is arranged on the positioning base frame 4, and the positioning base frame 4 is provided with a connecting flange 7 connected with the three-axis motion table, and the telescopic storage mechanism 3 is connected to the contact probe 2 and the non-contact type. The cleaning mechanism 5 is matched with the type probe 1, and the cleaning mechanism 5 is used to clean the surface of the workpiece to be inspected. Shading mechanism 6. By combining the non-contact probe 21 and the contact probe 2 on the positioning base 4, and performing telescopic control through the telescopic storage mechanism 3, the non-contact probe 21 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com