Tracking cut-off machine

A technology of cutting machine and sliding seat, which is applied in the direction of shearing device, device for cutting forming blanks, manufacturing tools, etc. It can solve the problems of profile conveying speed deviation, easy cracking of blade, equipment damage, etc., to avoid speed difference and cutting Great effect, great driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

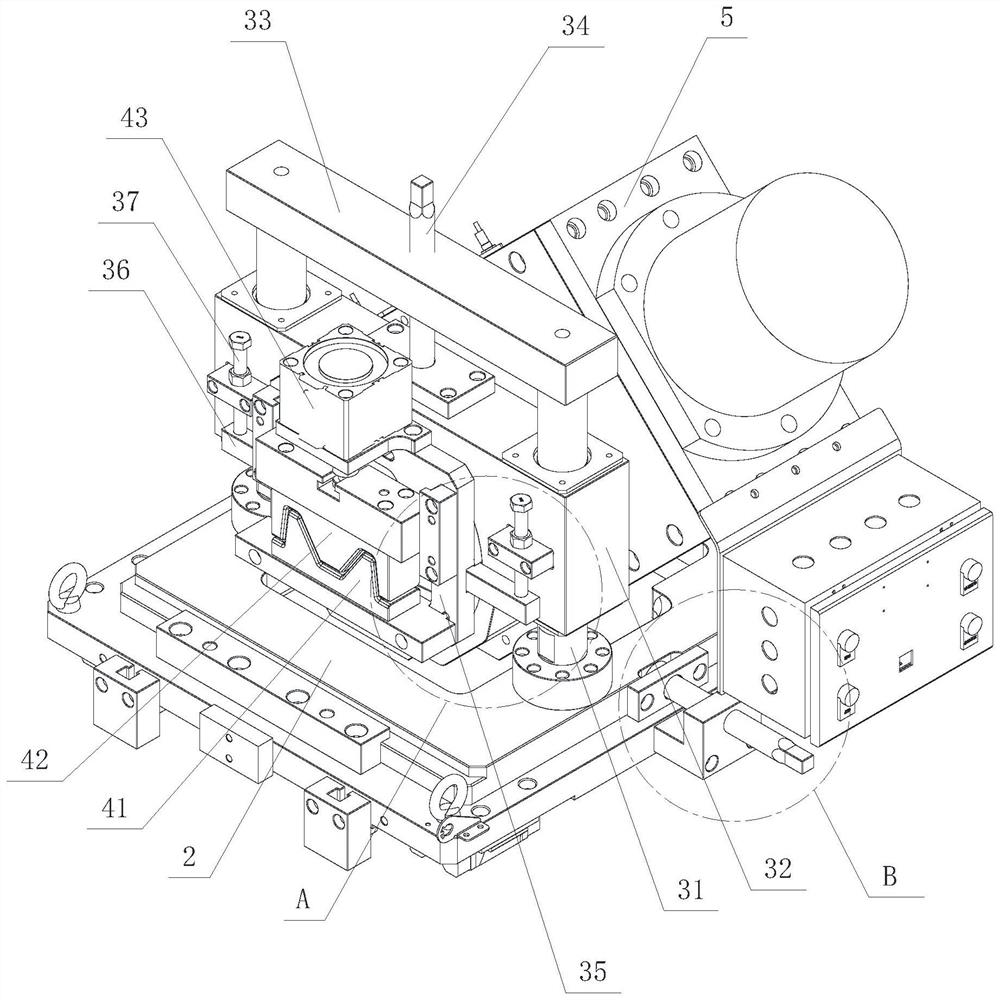

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

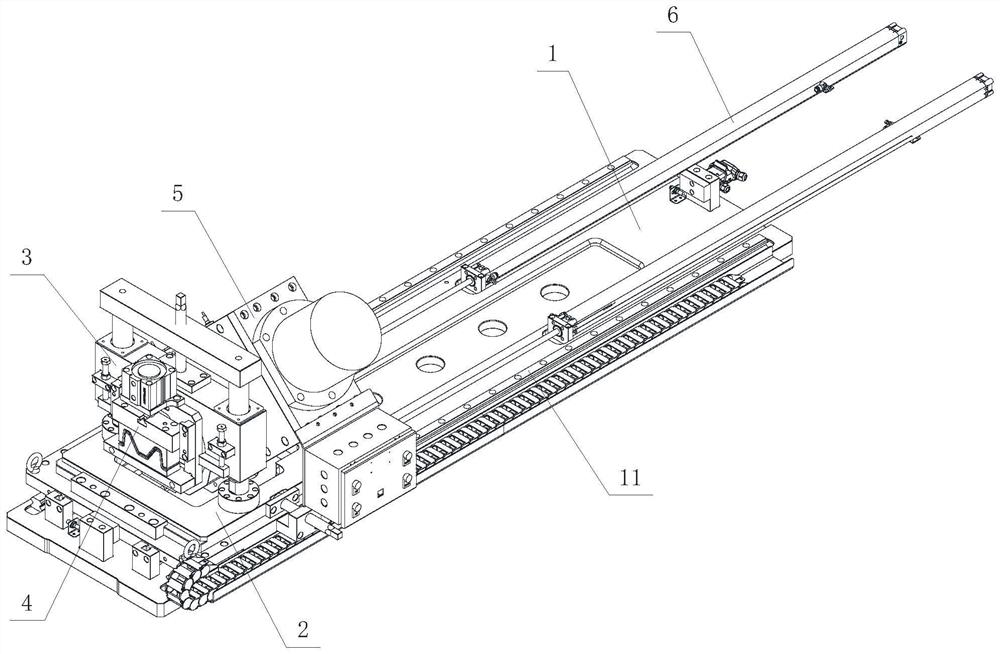

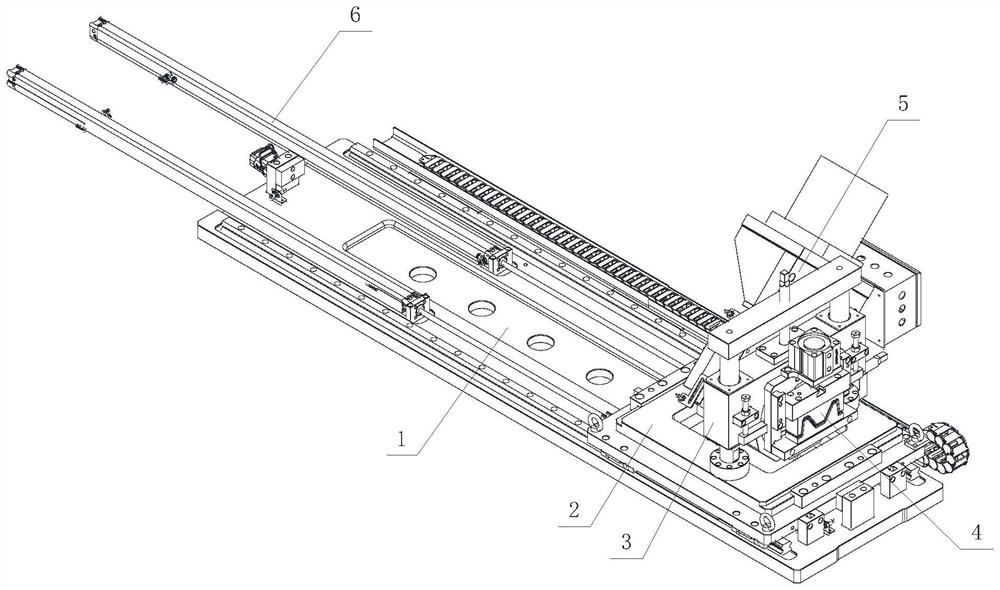

[0032] see Figure 1-Figure 8 , the present invention provides a tracking cutting machine for tracking and cutting profiles, which includes a bottom plate 1, a sliding seat 2, a mounting seat 3 and a gas spring 6;

[0033] The bottom plate 1 is arranged horizontally, and has a rectangular structure as a whole, and the length is 4-5 times the width, which is used as a mounting carrier and used for mounting other components. ;

[0034] The sliding seat 2 is horizontally slidably fitted on the bottom plate 1, and the sliding direction of the sliding seat 2 is parallel to the length direction of the bottom plate 1. In detail, the sliding direction of the sliding seat 2 is parallel to the conveying direction of the profiles. In this embodiment, on the bottom plate 1 Two guide rails (slide rails) 11 are provided, and a sliding block is provided on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com