Welding fixing device for steel structural member

A technology for steel structural parts and fixing devices, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of cracking and breaking at the welding place, inconvenient steel plate welding, and reducing work efficiency, etc., to strengthen the welding effect and improve the fixing. effect, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

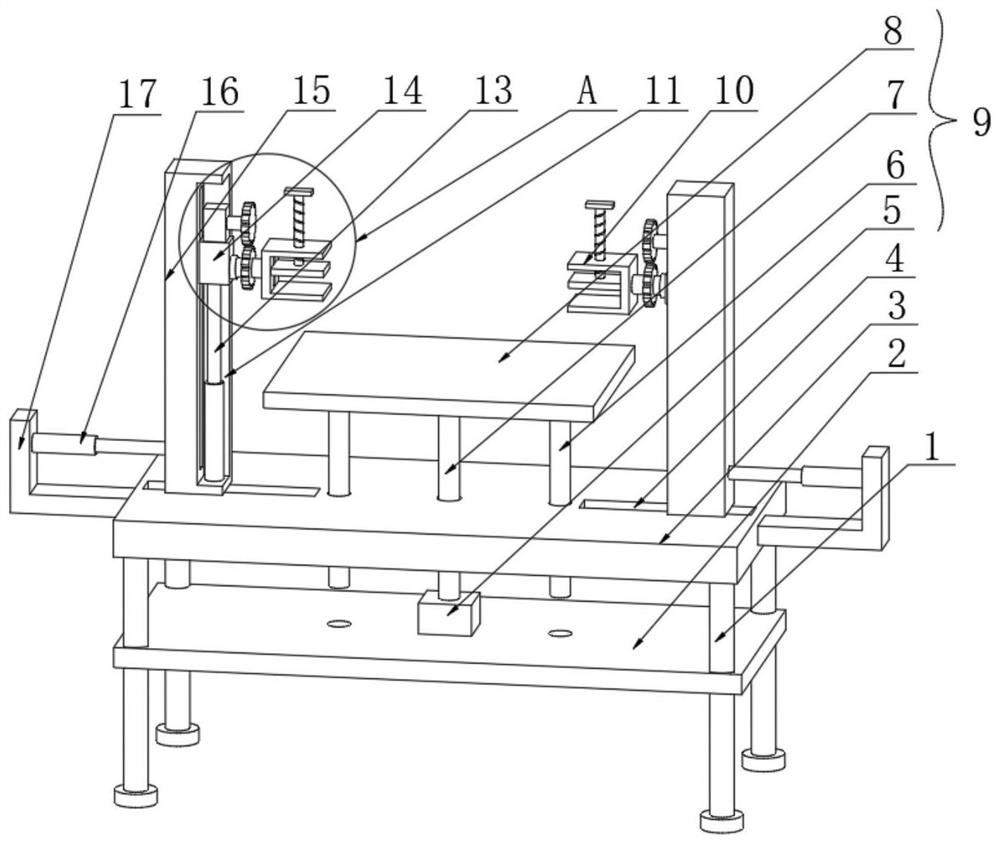

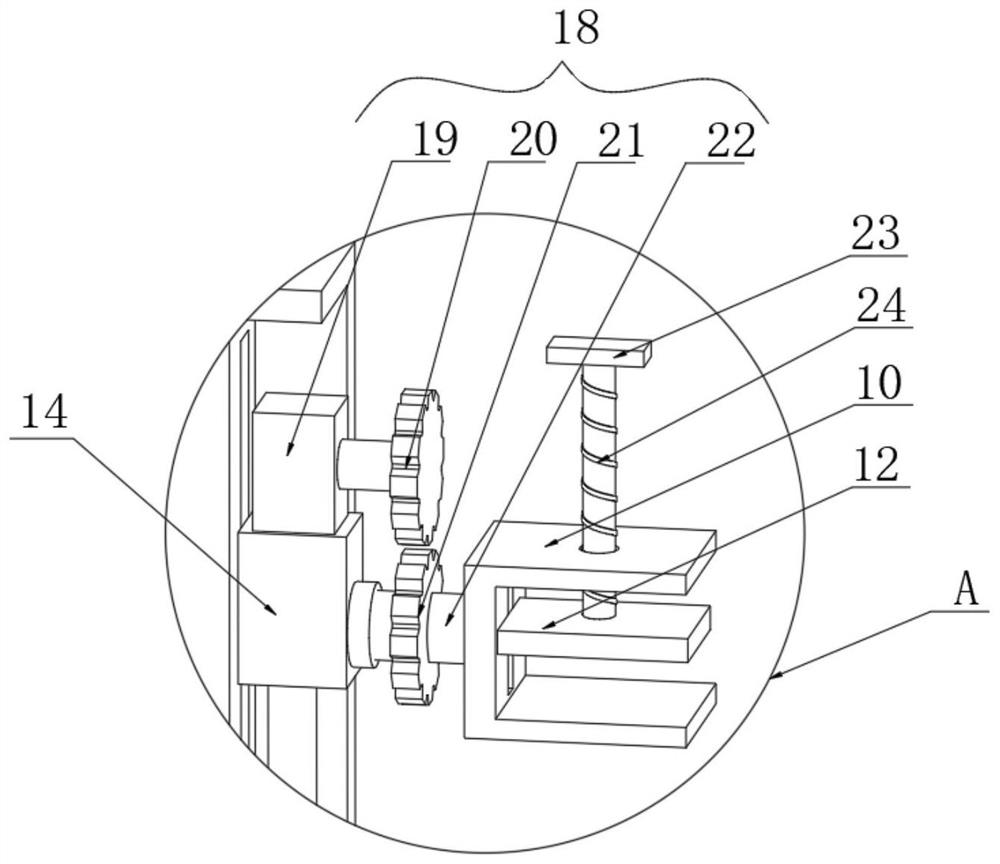

[0023] see figure 1 , the present invention provides a technical solution: a welding fixing device for a steel structure, comprising a top plate 3, four groups of support legs 1 are arranged at the bottom of the top plate 3, the four groups of support legs 1 are distributed in a rectangular array at the bottom of the top plate 3, Under the action of the leg 1, the overall fixing device is more stable. The bottom plate 2 is arranged under the top plate 3, and the placement component 9 is arranged on the top of the bottom plate 2. The placement component 9 is used to place the steel structure. There are fixed columns 15. The opposite side walls of the two sets of fixed columns 15 are provided with sliding grooves 11. The inner bottoms of the two sets of sliding grooves 11 are provided with hydraulic rods 13. The tops of the two sets of hydraulic rods 13 are provided with sliding blocks 14. The top of the sliding block 14 is provided with a rotating assembly 18 , and the opposite...

Embodiment 2

[0032] refer to figure 1 , this embodiment is different from the first embodiment in that: the placement assembly 9 includes a hydraulic cylinder 5 provided on the top of the bottom plate 2, the power output end of the hydraulic cylinder 5 is connected with a hydraulic rod 7, and a placement plate 8 is provided above the top plate 3, The top of the hydraulic rod 7 penetrates the bottom of the top plate 3 and is connected to the bottom of the placing plate 8. Under the action of the hydraulic cylinder 5, the hydraulic rod 7 is driven to move downward, and the hydraulic rod 7 drives the placing plate 8 to contact the upper surface of the top plate 3 to prevent the steel plate from turning over. When the plate 8 is placed, the steel plate is blocked.

[0033] There are limit rods 6 on the left and right sides of the bottom of the placing plate 8. The bottoms of the two sets of limit rods 6 penetrate through the top of the top plate 3 and the top of the bottom plate 2 and extend t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com