Tool for inlaying hemispherical head workpiece

A hemispherical head and workpiece technology, applied in the field of assembly fixtures, can solve problems such as inability to ensure installation accuracy, affect blood pump performance, and hidden dangers to patient safety, and achieve the effects of simple structure, impeller quality assurance, and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

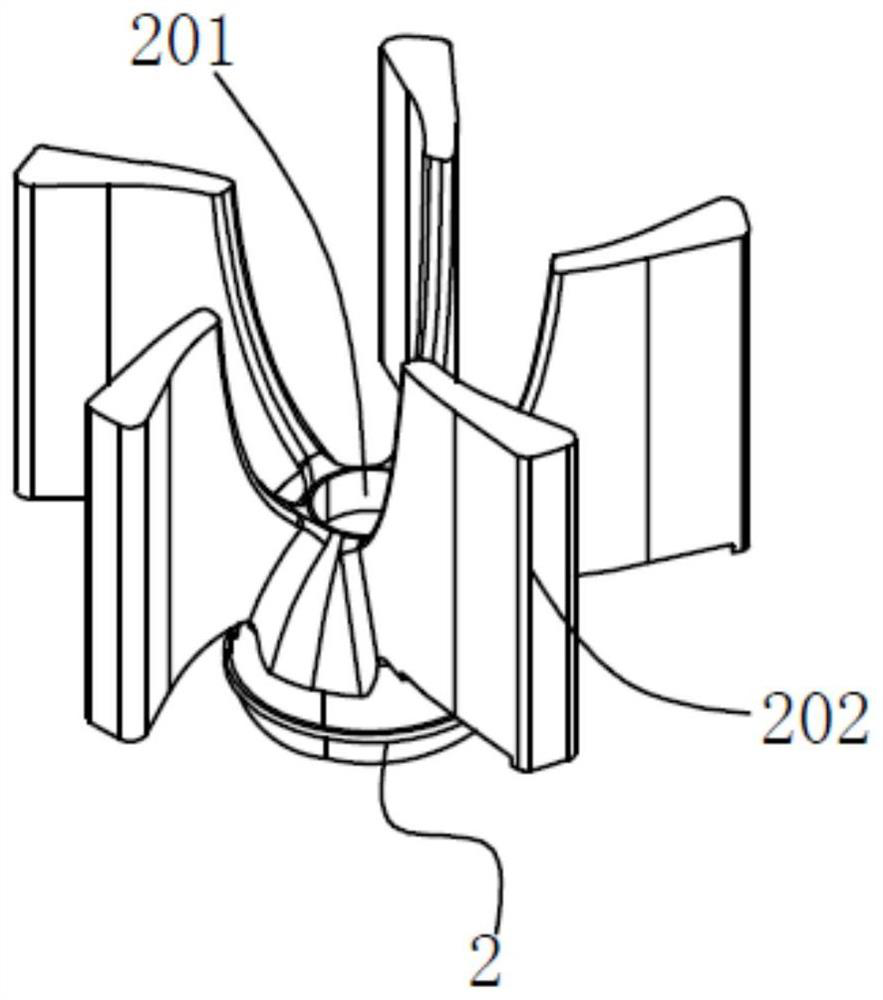

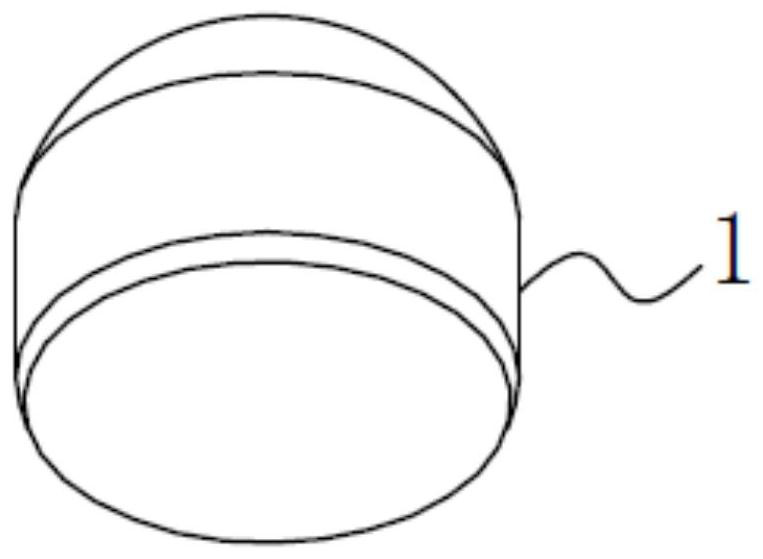

[0031] see figure 1 and figure 2 , The present invention provides a hemispherical head workpiece inlay tooling, which is used to inlay a workpiece 1 with a hemispherical head at one end and a cylinder at the other end into the installation groove 201 on one side of the impeller 2 .

[0032] see figure 1 In this embodiment, the impeller 2 includes a connecting seat and five blades 202 evenly distributed around the connecting seat, and the installation groove 201 is arranged on one side of the top of the connecting seat. The five blades 202 have the same structure, one end of each of them is connected to the connection seat, the other end of each of them is vertically upwardly extended, and an accommodation space is formed between the five blades 202 .

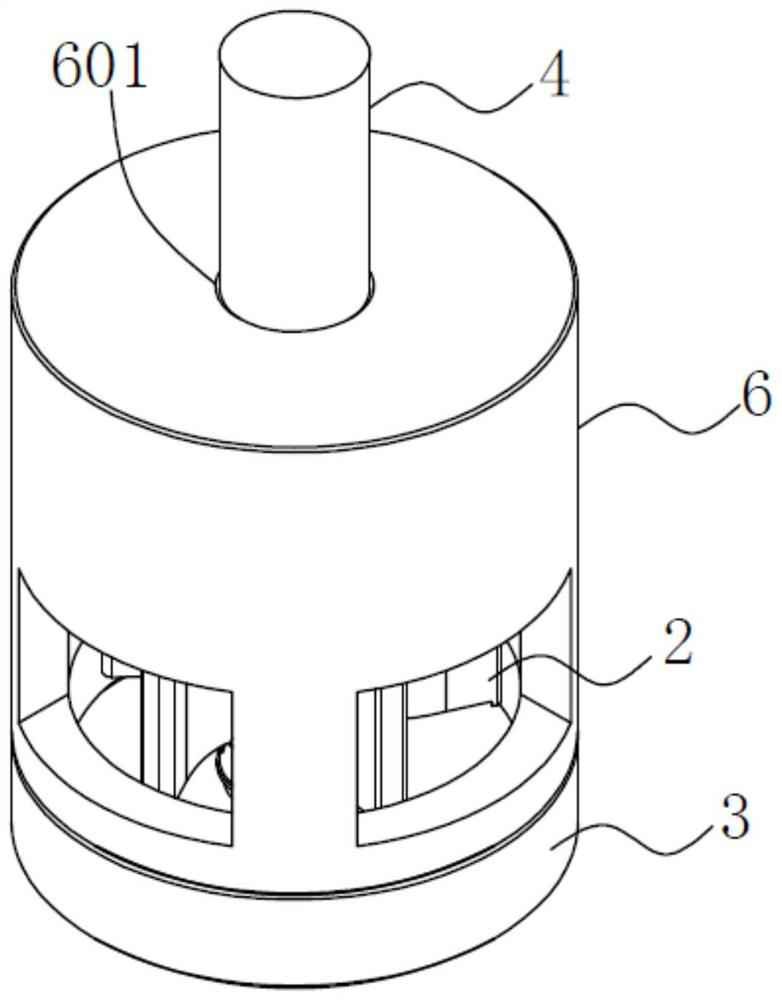

[0033] see Figure 3 to Figure 9 , the hemispherical head workpiece inlaying tooling in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com