GPU shoe sole full-automatic pouring forming device and preparation method

A fully automated, infusion-molding technology that is applied to home appliances, other home appliances, and household components. It can solve problems such as inability to produce printed soles, inability to make colors, and complex and fine patterns. It achieves light wearing, good anti-slip performance, clear pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments.

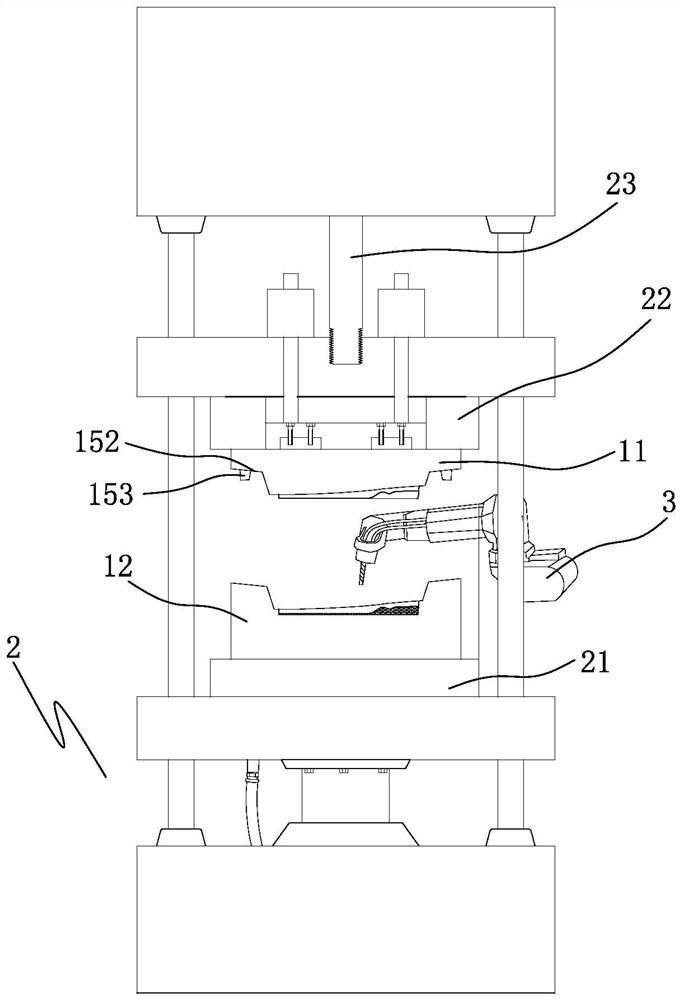

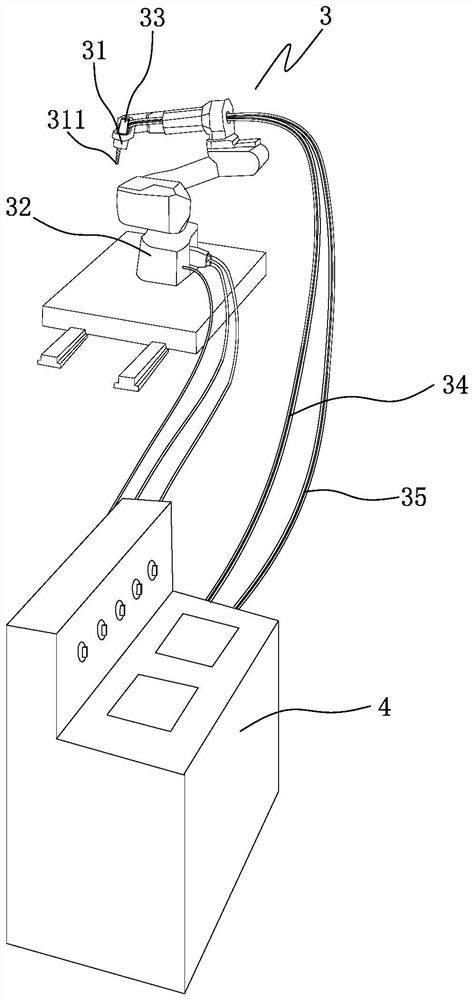

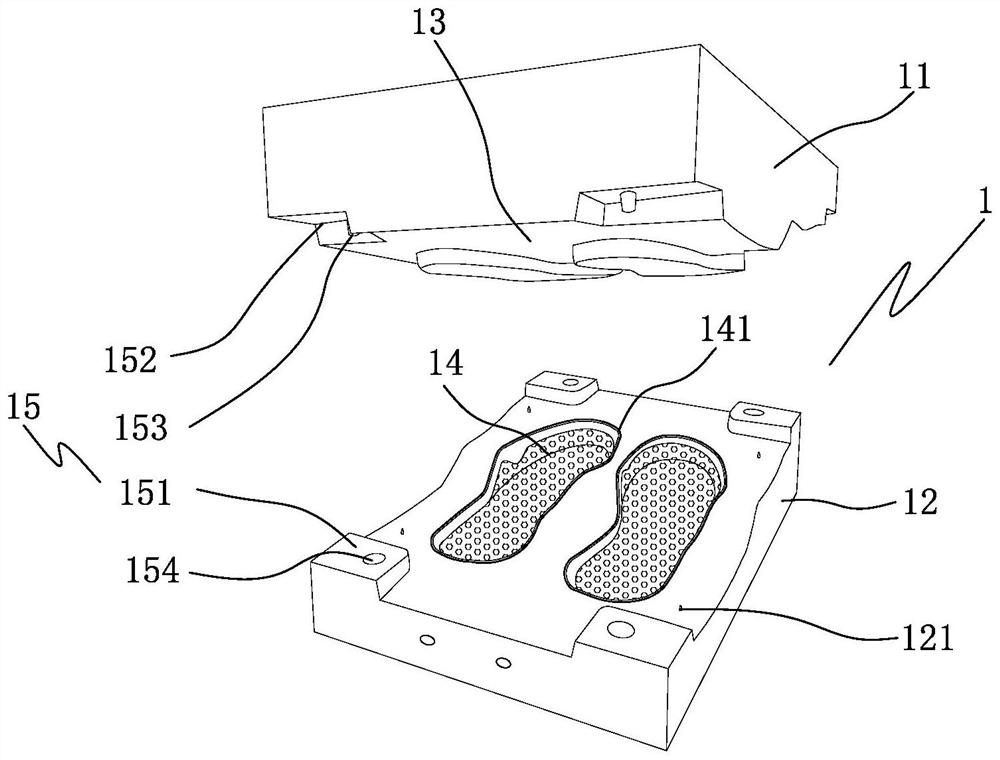

[0035] refer to Figure 1 to Figure 4 As shown, a fully automatic infusion molding device for GPU soles includes a sole mold 1 , a vacuum machine 2 , an automatic infusion robotic arm 3 and a controller 4 .

[0036] The GPU sole includes an outsole injection-molded by GPU liquid and a decorative layer 5 formed on the bottom surface of the outsole. Specifically, the GPU liquid is formed by mixing liquid A and liquid B in a volume ratio of 100:80; further, the decorative layer 5 Including the film cloth and the decorative colors and / or patterns attached to the film cloth. When preparing, you can choose your favorite decorative color and / or pattern according to your personal preference and attach it to the film cloth, and then compound it with the formed outsole. GPU sole.

[0037] Liquid A is composed of poly-1,4-butanediol adipate 99.1% (mass fraction), ultraviolet absorber 0.3% (mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotational viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com