Drive axle assembly control method and device, medium and electronic equipment

A drive axle assembly and control method technology, which is applied in the field of drive axle assembly control methods, media and electronic equipment, and devices, can solve the problems that the performance of the drive axle assembly cannot be fully utilized, and achieve the effect of improving control effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

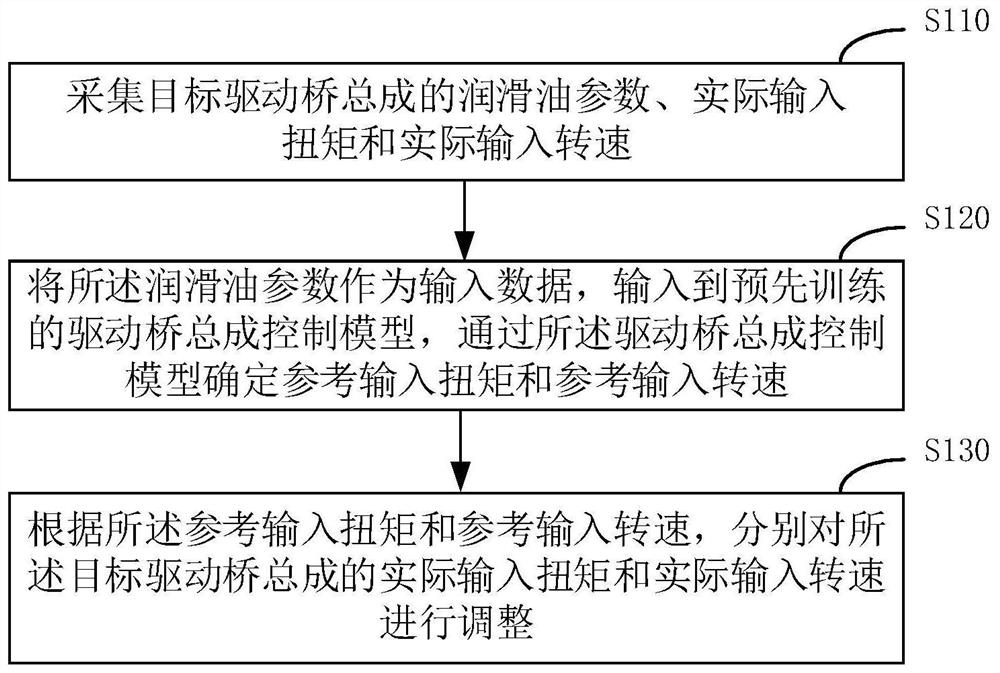

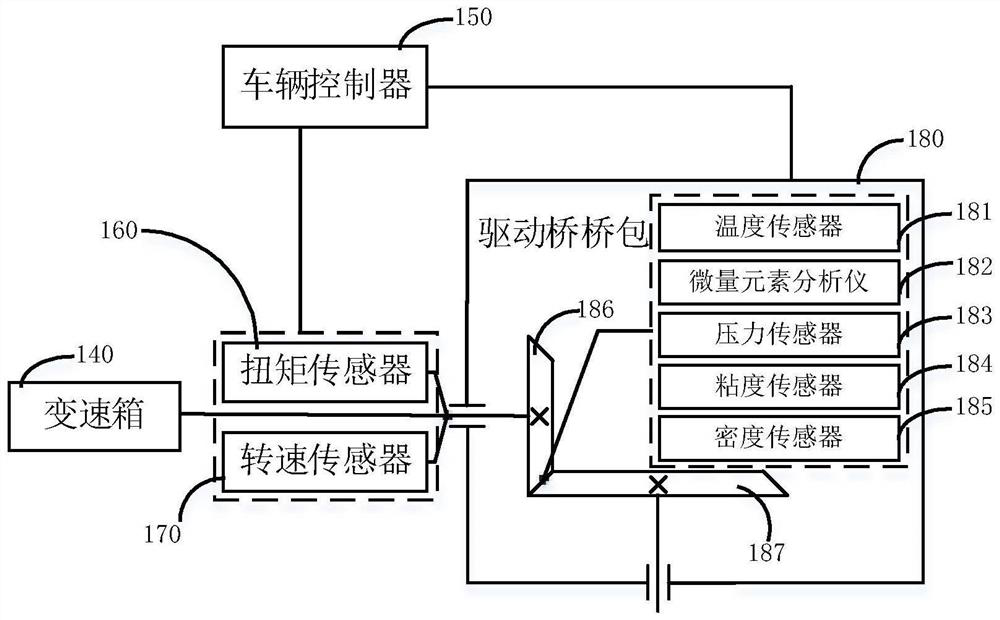

[0027] Figure 1A It is a flowchart of a method for controlling a drive axle assembly provided according to the first embodiment. This embodiment can be applied to the case of controlling the drive axle assembly. The method can be executed by a drive axle assembly control device. The bridge assembly control device can be implemented in the form of hardware and / or software, and can be integrated into the electronic equipment running the system.

[0028] like Figure 1A As shown, the method includes:

[0029] S110. Collect lubricating oil parameters, actual input torque and actual input rotational speed of the target drive axle assembly.

[0030] The target drive axle assembly refers to the drive axle assembly to be controlled. It can be known that the drive axle assembly has become one of the four major assemblies of the car, and the drive axle assembly includes the final gear and the differential. The drive axle assembly is used to reduce the speed and increase the torque of...

Embodiment 2

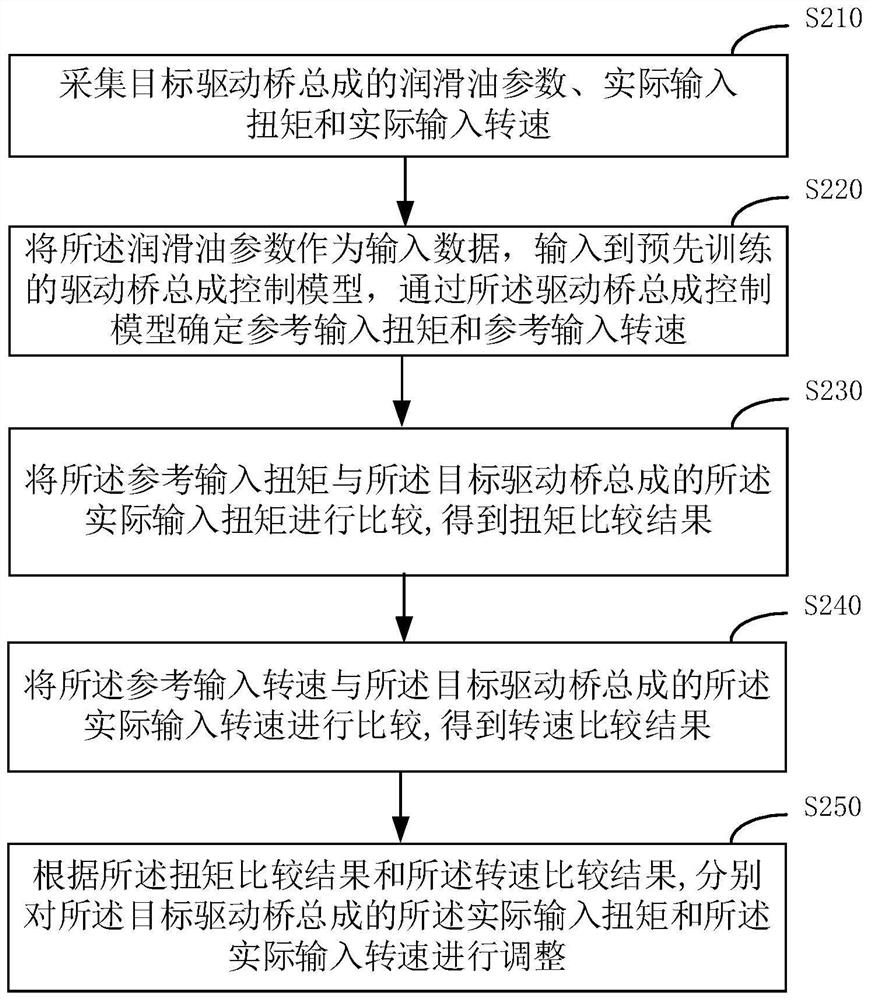

[0051] figure 2 It is a flowchart of a method for controlling a drive axle assembly provided according to the second embodiment. This embodiment is further optimized on the basis of the above-mentioned embodiment. Specifically, for the operation "According to the reference input torque and the reference input speed, the actual input torque and the actual input speed of the target drive axle assembly are respectively performed. Adjust" to refine.

[0052] like figure 2 As shown, the method includes:

[0053] S210. Collect lubricating oil parameters, actual input torque and actual input rotational speed of the target drive axle assembly.

[0054] S220. Input the lubricating oil parameters as input data into a pre-trained drive axle assembly control model, and determine a reference input torque and a reference input rotational speed through the drive axle assembly control model.

[0055] S230. Compare the reference input torque with the actual input torque of the target dri...

Embodiment 3

[0069] image 3 It is a flow chart of a method for controlling a drive axle assembly provided according to the third embodiment. This embodiment is further optimized on the basis of the above-mentioned embodiment. Specifically, the embodiment of the present application provides a training method for a control model of a drive axle assembly.

[0070] like image 3 As shown, the method includes:

[0071] S310. Obtain historical lubricating oil parameters of the drive axle assembly and historical input torque and historical input rotational speed corresponding to the historical lubricating oil parameters.

[0072]Among them, the historical input torque and historical input speed correspond to historical lubricating oil parameters, and the historical lubricating oil parameters of the drive axle assembly and the corresponding historical input torque and historical input speed are used to construct model training samples. The historical input torque, and the corresponding histori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com