Optical glass, optical prefabricated member, optical element and optical instrument

An optical glass and glass transition technology, applied in optical components, instruments, optics, etc., can solve problems affecting the application of optical glass, and achieve excellent chemical stability, bubble degree, and high refractive index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

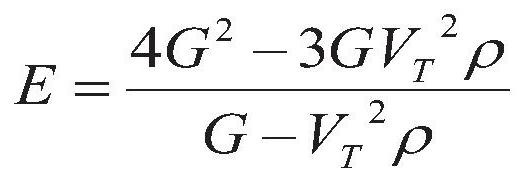

Method used

Image

Examples

Embodiment Construction

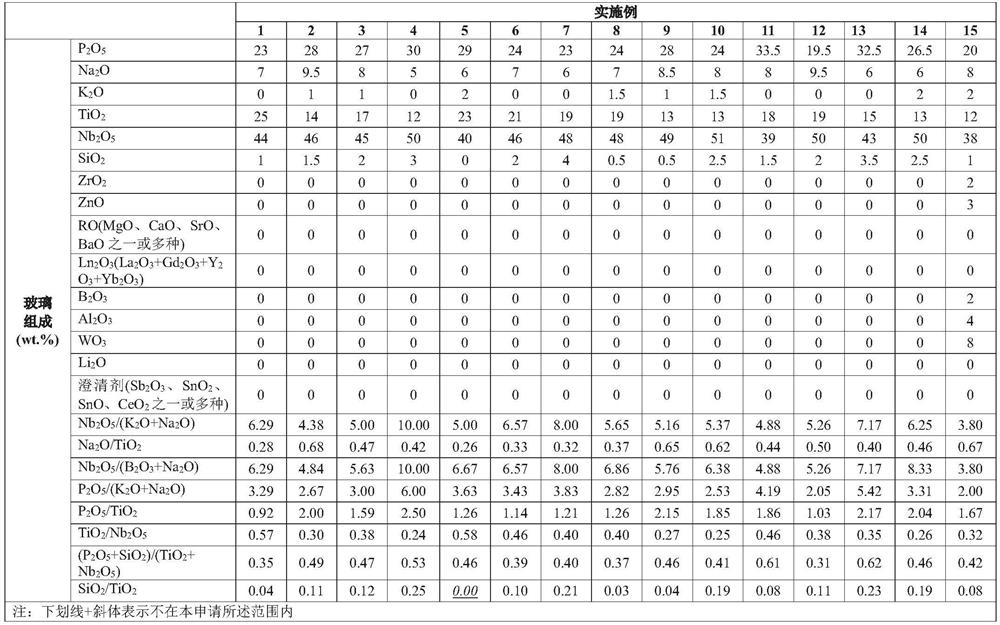

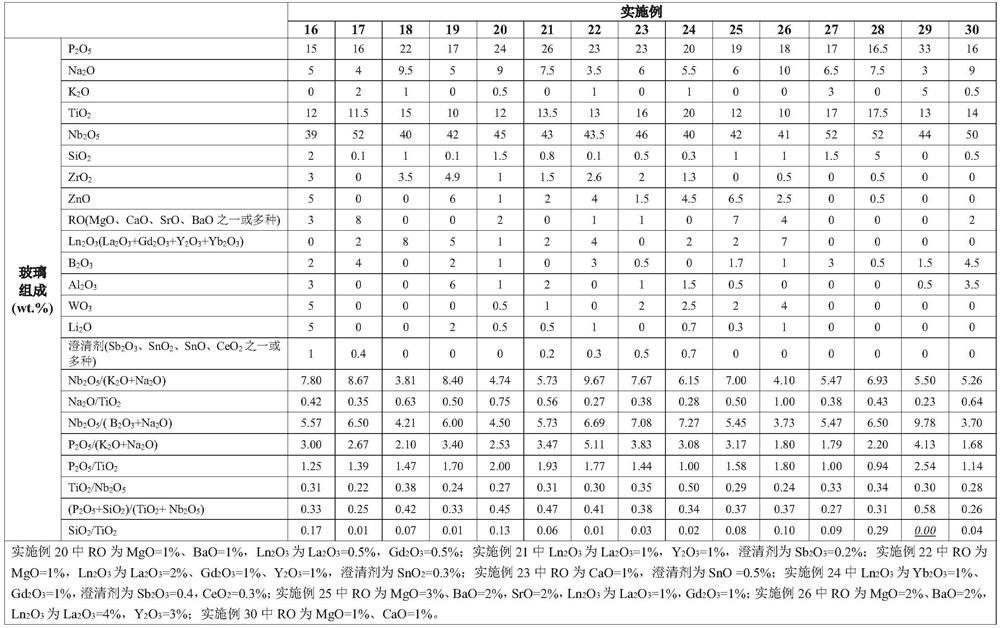

[0040] The specific embodiments of the present invention will be further described in detail below with reference to the examples. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention. In this specification, unless otherwise specified, the content of each component (component) is expressed as a percentage by weight relative to the total amount of glass substances in the composition converted into oxides. Here, the "composition in terms of oxides" means that when the raw material serving as the optical glass component of the present invention is melted and decomposed and converted into oxides, the total amount of the oxides is taken as 100%.

[0041] Unless the specific case indicates otherwise, the numerical ranges recited herein include upper and lower limits, "above" and "below" include the endpoints, all integers and fractions within the range and not limited to the defined range. specific values lis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com