T-shaped assembly type node connecting structure of double steel plate-concrete composite shear wall

A technology of concrete shear wall and composite shear wall, applied in the direction of structural elements, walls, building components, etc., can solve the problems of insufficient force transmission effect, unsatisfactory seismic performance, and indirect force transmission methods, and achieves the goal of solving transmission problems. The force path is not direct, the overall production efficiency is improved, and the setting difficulty is solved.

Pending Publication Date: 2022-08-05

GUILIN UNIVERSITY OF TECHNOLOGY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] When the steel plate concrete composite shear wall is connected to the steel beam, it is generally reinforced by attaching a reinforcing plate or thickening the plate on both sides of the flange of t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

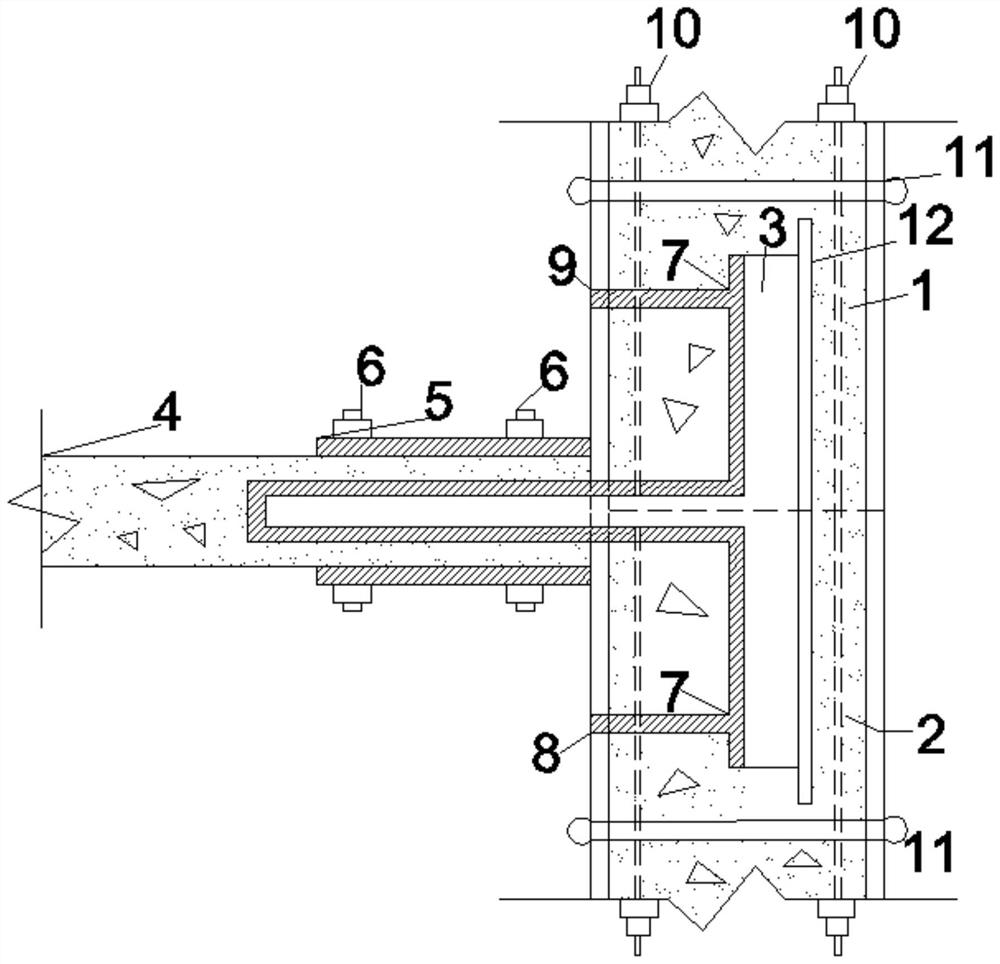

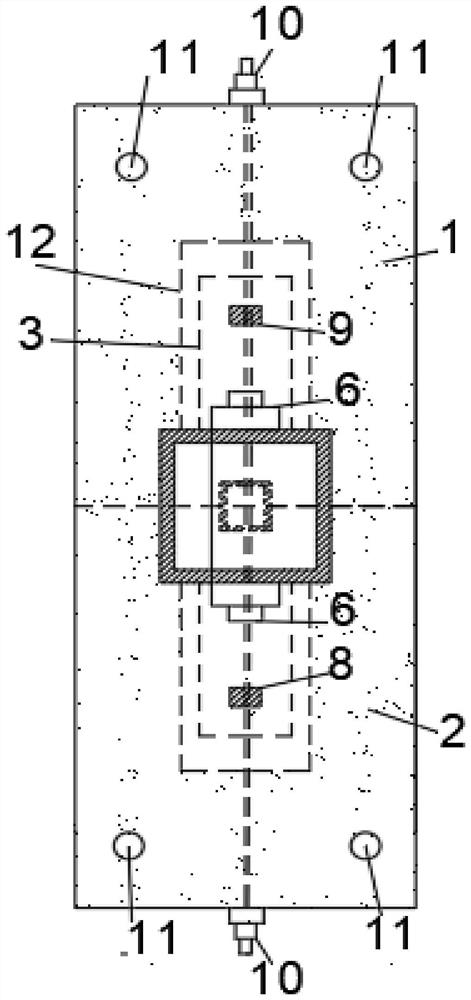

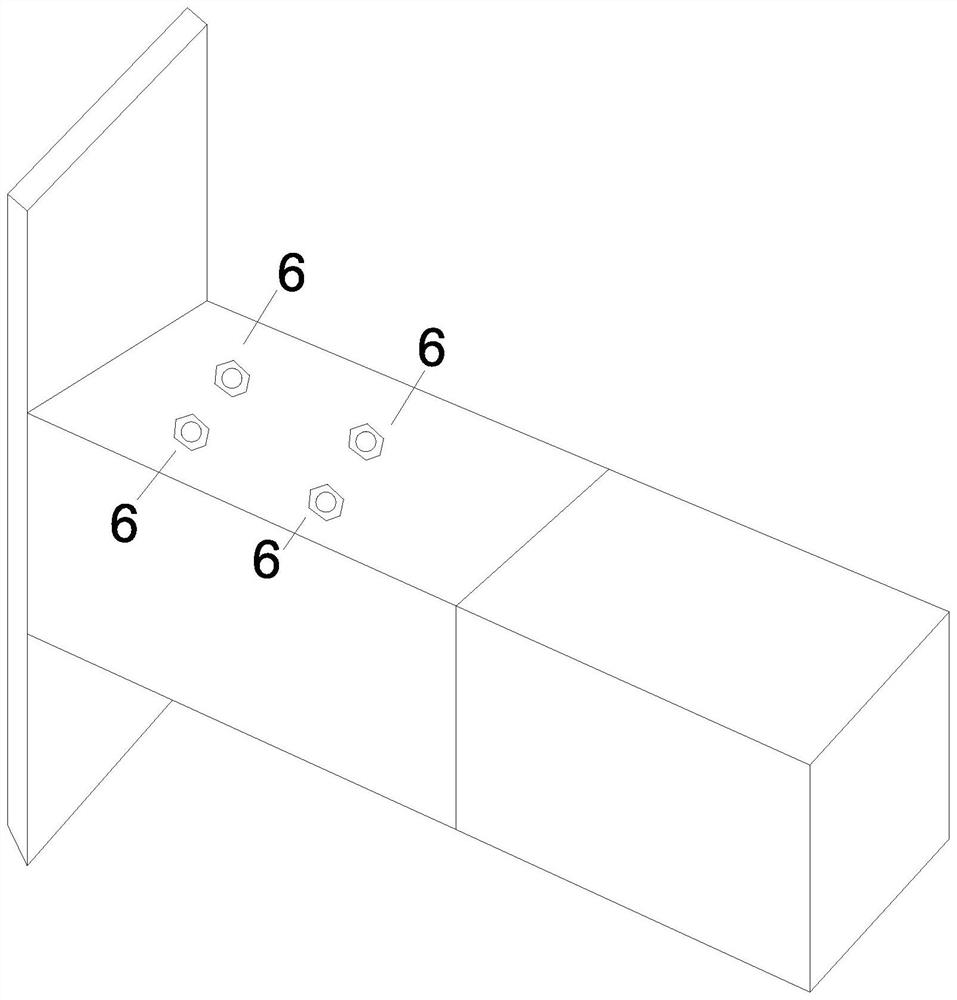

A T-shaped assembly type joint connecting structure of a double-steel-plate-concrete composite shear wall comprises the prefabricated assembly type shear wall, a concrete structure layer, T-shaped steel connecting pieces, embedded steel plates, sleeves, prestressed tendons, horizontal connecting tendons and the like. The prefabricated assembly type shear wall comprises two steel plates which are oppositely arranged, and the two steel plates are filled with concrete. The penetrating fabricated shear wall is provided with horizontal connecting ribs, two annular blocking rings are arranged at the positions, corresponding to the steel plates on the two sides, of each horizontal connecting rib, the position between the two steel plates is filled with a concrete interlayer, and prestressed steel bars are preset in the shear wall so that the shear capacity of the shear wall can be improved. The node T-shaped steel and the prefabricated shear wall are manufactured into a whole in an assembly type factory and welded to a pre-buried steel plate in an electric welding mode. And after the T-shaped steel is welded stably, grouting materials are preset in the prefabricated grouting hole channels. Sleeves are vertically welded outside the two steel plates and are bonded and reinforced through epoxy resin glue, and the sleeves and the rectangular beams are connected through high-strength bolts and expansive cement.

Description

technical field [0001] The invention relates to the field of prefabricated node connection structures, in particular to a T-shaped prefabricated node connection structure of a double steel plate-concrete composite shear wall. Background technique [0002] With the continuous acceleration of urbanization in our country, the construction industry has also been continuously improved. In order to meet the needs of housing, the construction industry continues to expand its scale, enhance its technology and improve its construction quality. Prefabricated buildings are favored by the construction industry due to their low cost, energy saving, environmental protection, and high efficiency. With the continuous expansion of demand in the construction industry, the requirements for prefabricated structural nodes are also getting higher and higher. [0003] When the steel plate-concrete composite shear wall is connected to the steel beam, it is generally reinforced by attaching reinfor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B2/00E04B1/41E04C5/08E04B1/98E04H9/02

CPCE04B2/00E04B1/41E04C5/08E04B1/98E04H9/021

Inventor 方威莫时旭陈震杜思雨

Owner GUILIN UNIVERSITY OF TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com