Device for installing wind power generation fan and tower drum and construction method of device

A technology for wind power generation and towers, which is applied to the installation/supporting of wind power generators, wind power generation, wind power generators, etc. It can solve the problems of increasing the cost of hoisting machinery, the difficulty of hoisting, and the high cost of renting hoisting equipment to achieve safe, effective and fast Effect of construction, reduction of installation cost and construction time, reduction of installation cost and impact on surrounding buildings of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

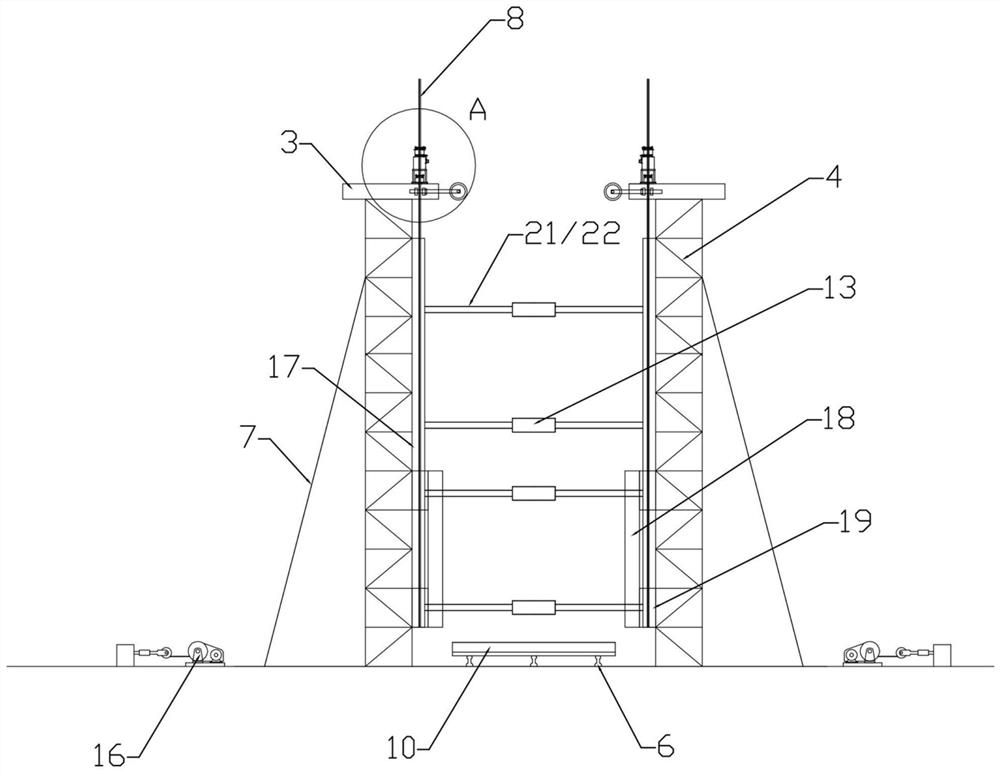

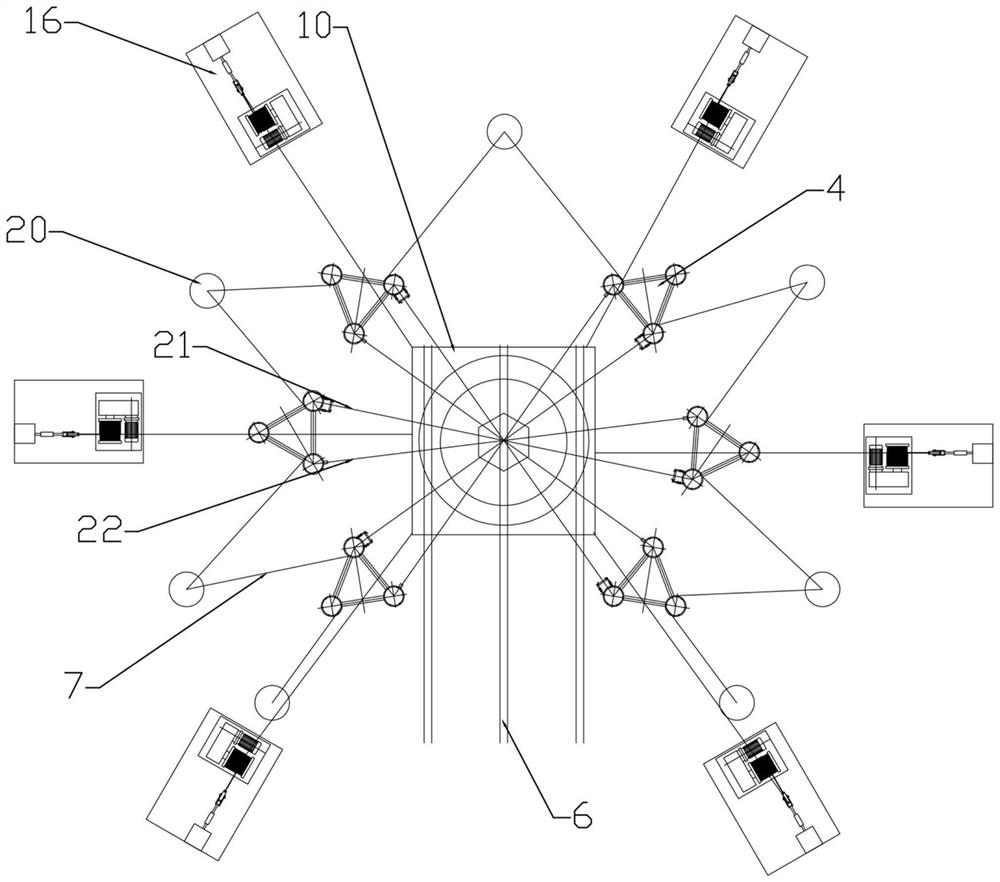

[0048] As shown in the figure, a device for installing a wind power generator and a tower includes a tower foundation 1, a guide rail installation platform foundation 9, a load-bearing support frame foundation 2, a cable anchor foundation 20, and an installation stabilization device 16. The load-bearing support The frame foundation 2 is arranged around the tower foundation 1, and the cable anchor foundation 20 is arranged on the periphery of the load-bearing support frame foundation 2;

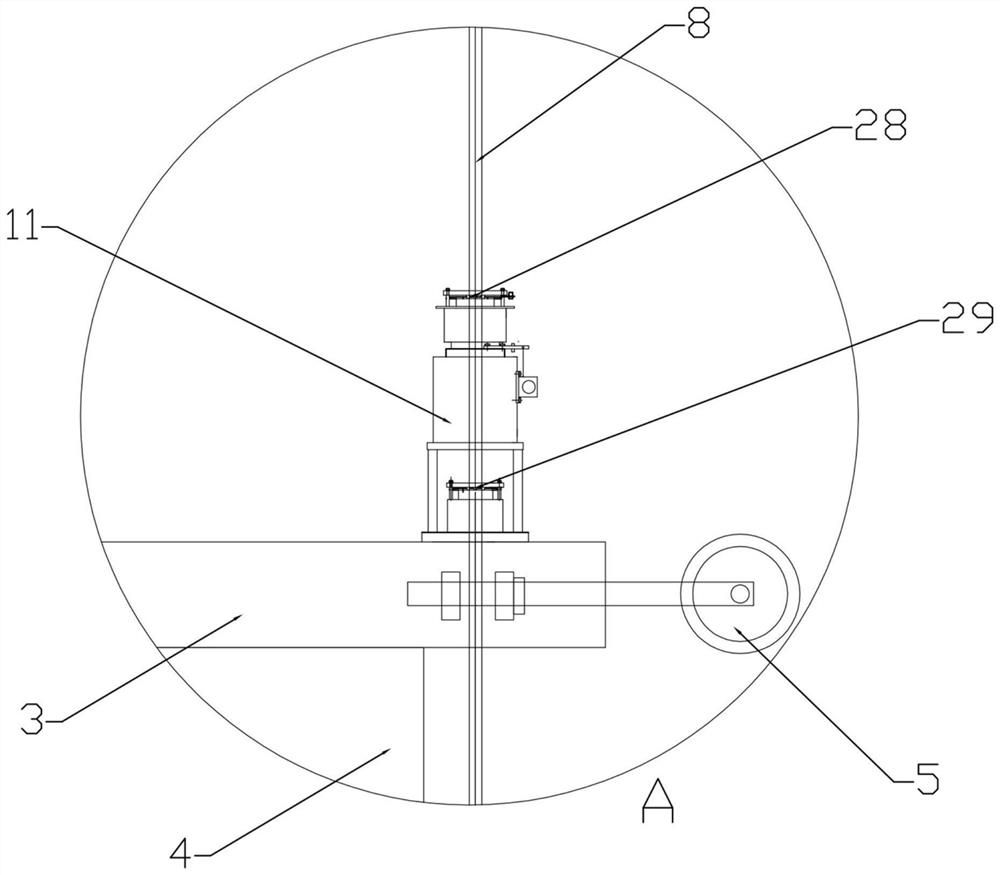

[0049] The load-bearing support frame base 2 is provided with a load-bearing support frame 4, the top of the load-bearing support frame 4 is provided with a reinforced connecting beam 3, and the end of the reinforced connecting beam 3 close to the tower foundation 1 is fixedly provided with an anti-tilt. The guiding device 5, the top of the reinforcement connecting beam 3 is provided with a jacking jack 11, the lifting jack is longitudinally provided with a steel strand 8, and the side of the l...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 is: the tower 12 is divided into two ends as a whole for jacking and installation, including the following steps:

[0065] 1) The tower as a whole is divided into standard tower sections with a height of 5 meters; when each standard section of the tower is jacked up from the sliding platform 10, the standard section of the tower is lifted to the bottom and is 10 5.1 away from the sliding platform height in meters;

[0066] 2) When the top surface of the standard section of the topmost section tower is lifted to a height of about 5 meters above the load-bearing platform, the lifting and installation of the first section of the tower 12 are completed, and the installation of the fan engine room 14 is carried out; the fan After the installation of the engine room 14 is completed, the jacking and installation of the standard section of the tower continues until the height of the tower 12 reaches the standard.

Embodiment 3

[0068] The difference between this embodiment and Embodiment 2 is that the blades 30 of the fan are installed piece by piece through the chopping rod crane 15, including the following steps:

[0069] 1) After the installation of the fan cabin 14 is completed, two blades 30 are installed above the fan cabin 14; the directions of the two blades 30 are inclined upward;

[0070] 2) When the height of the tower 12 rises to a height just enough to install the third blade 30, install the third blade below the fan nacelle 14, and the direction of the blade 30 is vertically downward.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap