Magnetic drive pump with anti-falling structure

A magnetic pump and anti-shedding technology, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, can solve problems such as loose screws or misalignment, overall vibration, and structural shedding, and achieve weight reduction. Improves stability and impact resistance and reduces production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

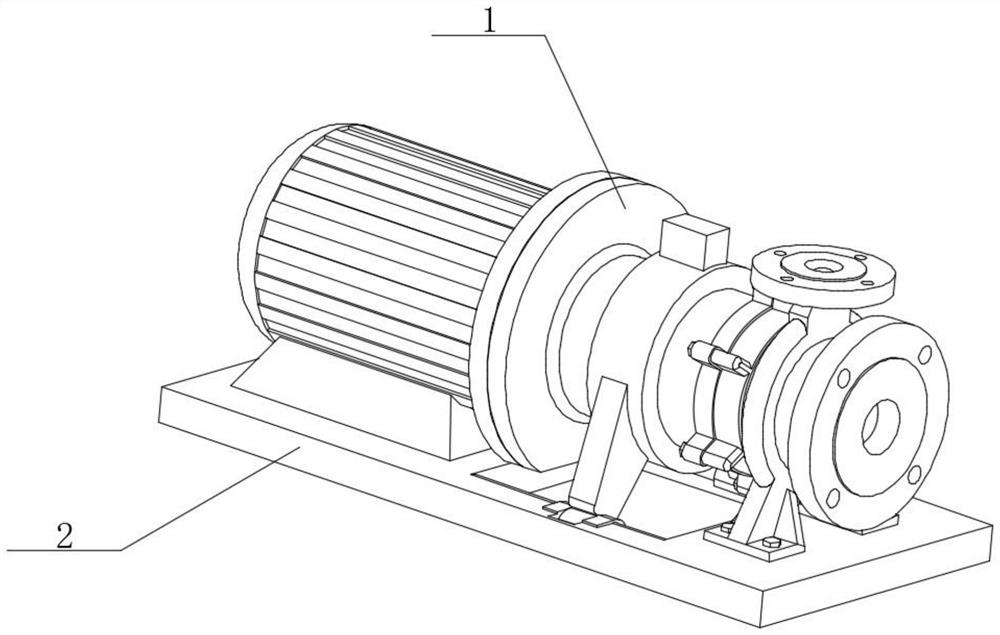

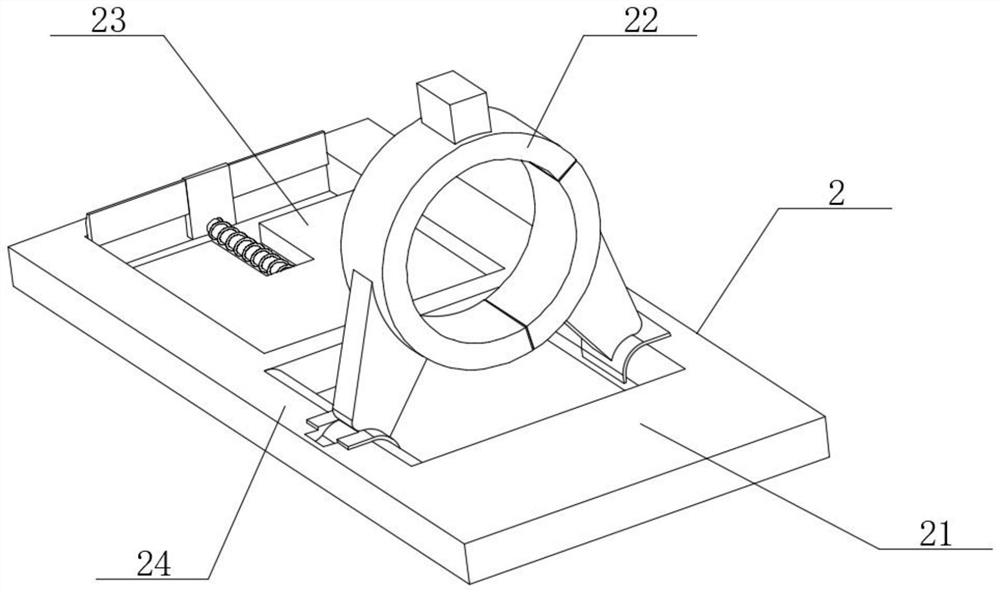

[0037] like figure 1 and figure 2 As shown, the present invention provides a technical solution: a magnetic pump with an anti-shedding structure, comprising a magnetic pump body 1, the bottom of the magnetic pump body 1 is provided with an anti-dropping structure 2, and the anti-dropping structure 2 includes a rectangular base 21 , the connecting frame support frame 22, the motor limiting frame 23 and the adjusting side post 24, the connecting frame supporting frame 22 is installed on the top of the rectangular base 21, the motor limiting frame 23 is installed inside the rectangular base 21, and the adjusting side post 24 is installed on the connecting frame At the junction of the support structure 22 and the rectangular base 21 , the connecting frame support structure 22 is located in the middle of the rectangular base 21 , and the motor limiting structure 23 is located at one end of the rectangular base 21 .

[0038] In this embodiment, the connecting frame supporting stru...

Embodiment 2

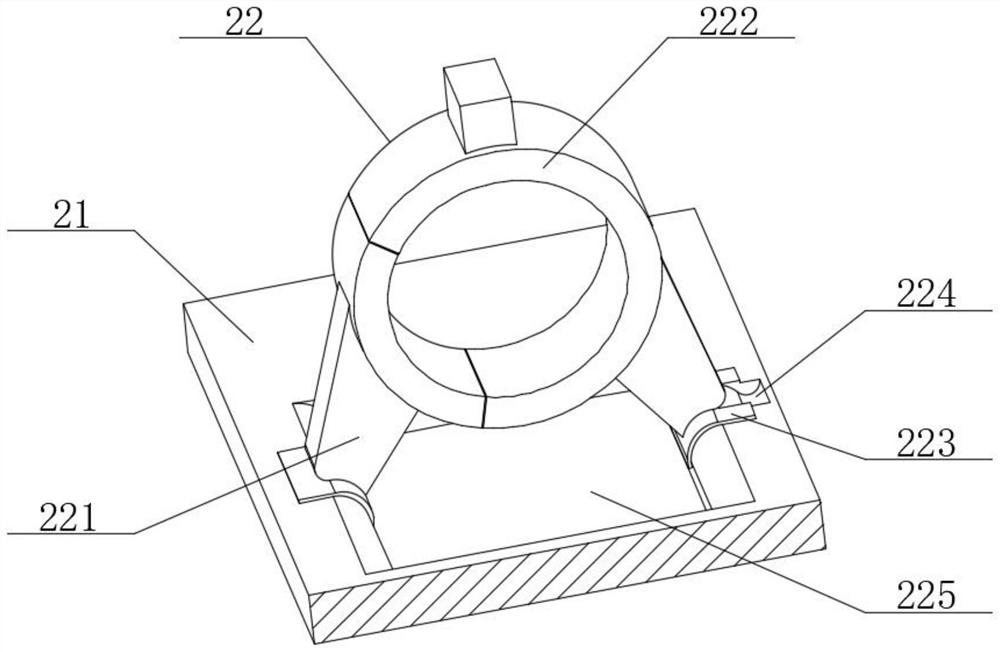

[0040] like Figure 1-4 As shown, the connecting frame support structure 22 includes a fixed bracket 221 and a movable bracket 222, the fixed bracket 221 is located on one side of the rectangular base 21, the movable bracket 222 is located on the other side of the rectangular base 21, and the top of the movable bracket 222 is connected to the fixed bracket 221. The top is connected, a limit card 223 is set at the intersection of the movable bracket 222 and the rectangular base 21 , and a limit recess 224 is set at the intersection of the limit card 223 and the rectangular base 21 , and the limit recess 224 is located on the upper surface of the rectangular base 21 One side of the limit card 223 is provided with a fixed plate 225, and a through hole 226 is opened at the intersection of the rectangular base 21, the fixed bracket 221 and the movable bracket 222, and the through hole 226 is located below the fixed bracket 221 and the movable bracket 222. The plate 225 is located o...

Embodiment 3

[0043] like figure 2 and Figure 5 As shown, the adjusting side post 24 includes a central rotating shaft 241, a rotating ring 242, a butting plate 243 and a buffer side plate 244. The rotating ring 242 is sleeved on the outer wall of the central rotating shaft 241, and one end of the butting plate 243 is connected to the outer wall of the rotating ring 242. , one end of the buffer side plate 244 is connected to the outer wall of the butt plate 243, the buffer side plate 244 is located on one side of the butt plate 243, the top of the butt plate 243 and the buffer side plate 244 are connected to the inside of the support rod 2221, and the central rotating shaft 241 is installed inside the rectangular base 21 .

[0044] In this embodiment, the central rotating shaft 241 serves as the circular shape of the entire adjusting side post 24, and the rotating ring 242 is connected to the supporting rod 2221 in the movable bracket 222 through the butting plate 243 and the buffer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com