Auxiliary tool and method for carrying out tensile test on engine part

A technology for tensile testing and auxiliary tooling, which is applied in the direction of engine testing, machine/structural component testing, and measuring devices. The effect of quality hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the specific embodiments in the accompanying drawings.

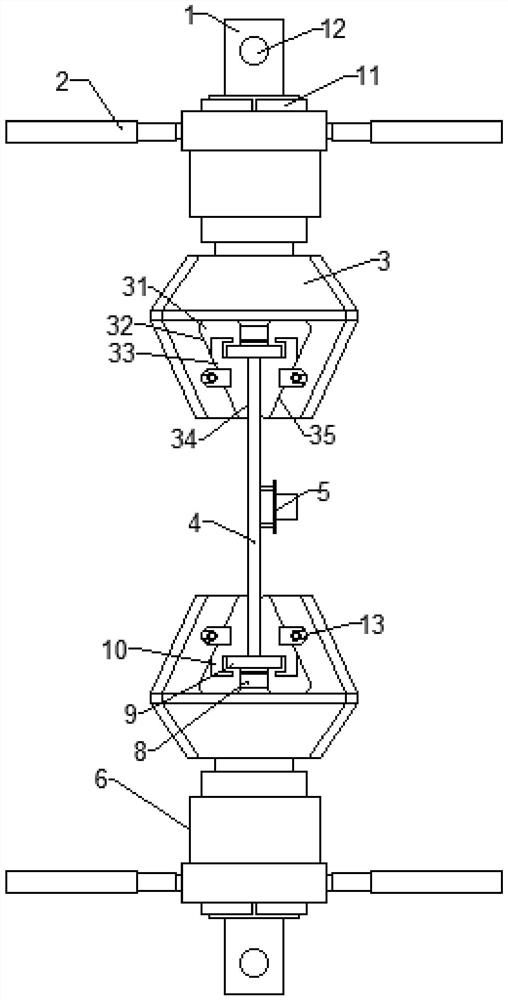

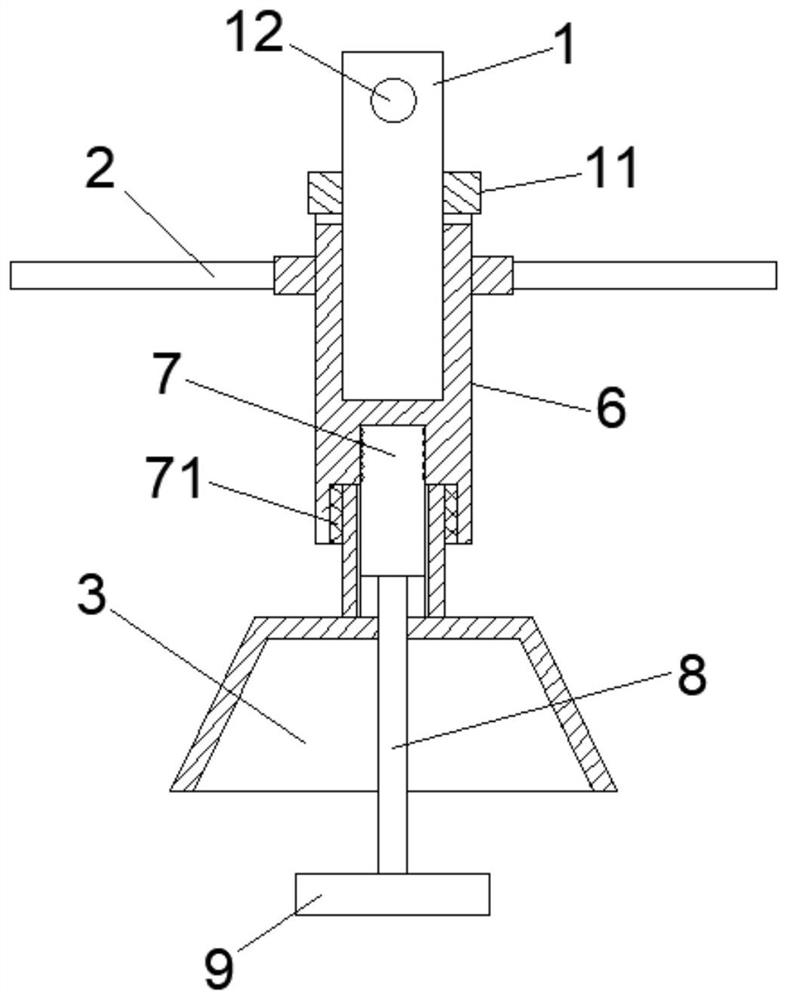

[0024] see Figure 1-2 , an auxiliary tool for tensile testing of engine parts, including an extensometer 5, two clamping mechanisms for clamping the upper and lower ends of the pattern 4, the extensometer 5 is installed in the middle of the pattern 4, and the clamping mechanism includes The clamping body 3, one end of the clamping body 3 is provided with a jaw 31, the inner walls of both sides of the jaw 31 are provided with a first wedge surface 32, and the two sides of the inner cavity of the jaw 31 are respectively provided with clamping blocks 33, two clamping The side of the block 33 close to each other is provided with a clamping portion 34, the side of the two clamping blocks 33 away from each other is provided with a second wedge surface 35 slidably connected with the first wedge surface 32, and the other end of the clamping body 33 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com