EBSD sample dismounting table and EBSD detection method of sample

A technology of samples and mounting holes, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inconvenient detection, and achieve the effects of convenient sampling, improved stability, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

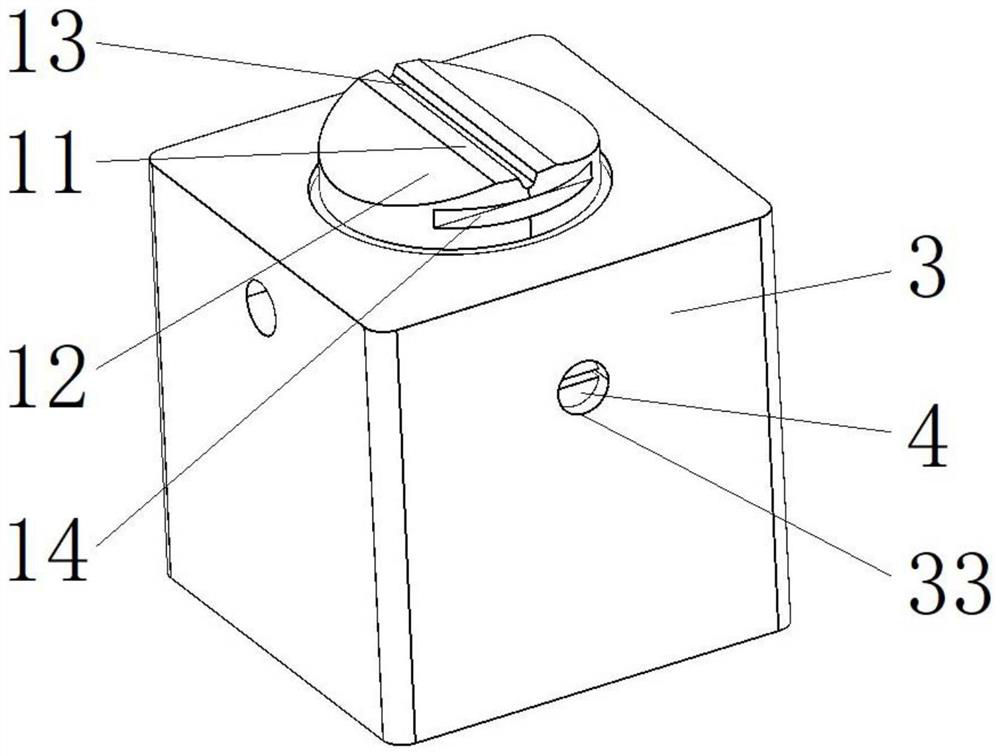

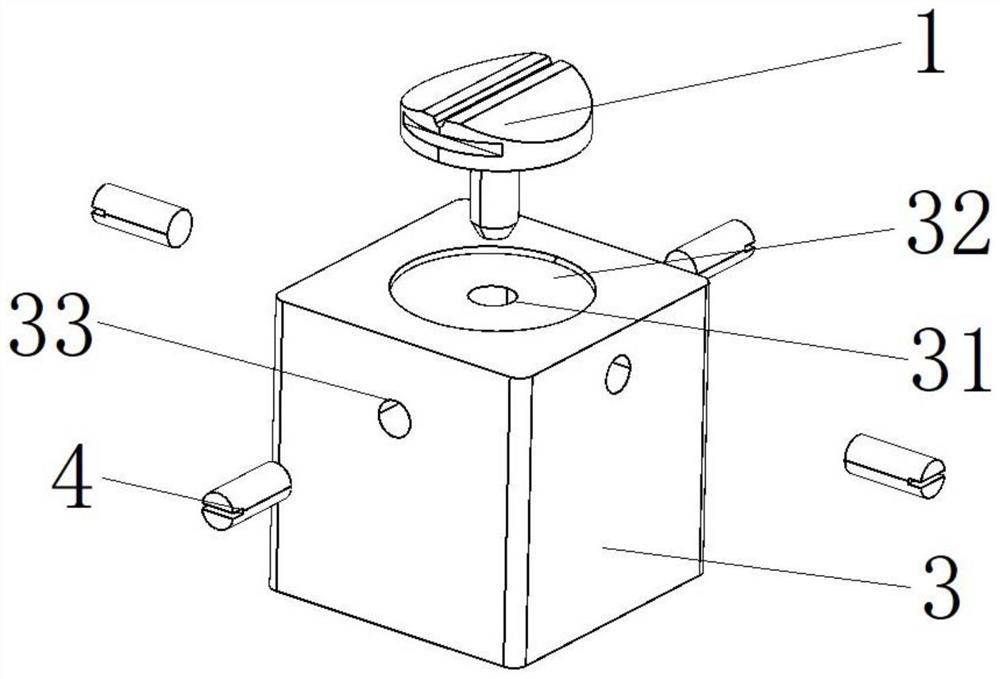

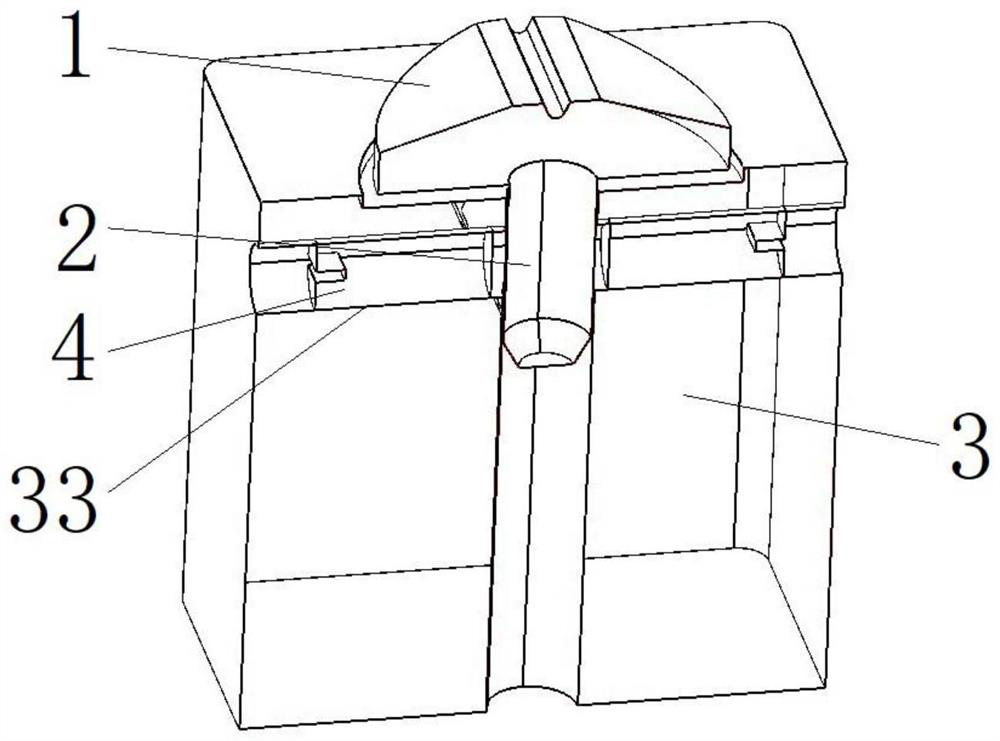

[0039] This example provides Figure 1 to Figure 4 An EBSD sample disassembly and assembly stand as shown includes a sample disassembly and assembly body 1, a support body 2, a base 3 and a locking member 4. The EBSD sample disassembly and assembly stand can disassemble and install samples and can be used for EBSD detection. Specifically, the sample disassembly and assembly body 1 can be provided in a cylindrical or prismatic shape or other shapes; the base 3 can be provided in a rectangular parallelepiped or cylindrical shape or other shapes; the samples can be spring steel samples or others.

[0040] like figure 1 and figure 2 As shown, the surface of the sample disassembly and assembly body 1 away from the base 3 is provided with a fixed bonding surface 11, a conductive filling surface 12, a function recess 13 and a clamping recess 14, wherein the fixed bonding surface 11 is used for bonding the sample. The conductive filling surface 12 is connected to the fixed bonding su...

Embodiment 2

[0048] The present embodiment provides a method for detecting EBSD of a sample, based on the EBSD sample disassembly and assembly platform in Embodiment 1, comprising the following steps:

[0049] Installation: Adhere the sample to the fixed adhesive surface 11 of the sample disassembly and assembly body 1 through an adhesive such as 502 glue, and apply conductive glue such as silver conductive glue to the surface of the sample close to the base 3 and The sample can be electrically conductive between the conductive filling surfaces 12 of the sample disassembly and assembly body 1. At this time, the sample disassembly and assembly body 1 is locked on the base 3 by the locking member 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com