Wiring method of ZD6 type switch machine for test

A wiring method and switch machine technology, applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve the problems of non-existence, difficulty in testing switch machines, and inability to satisfy switch machines, so as to reduce intermediate operations Links, improve test efficiency, and meet the effect of on-site use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention to achieve the predetermined purpose, the specific implementation, structural features and effects of the present invention are described in detail below with reference to the accompanying drawings and examples.

[0027] Example and Example Application 1

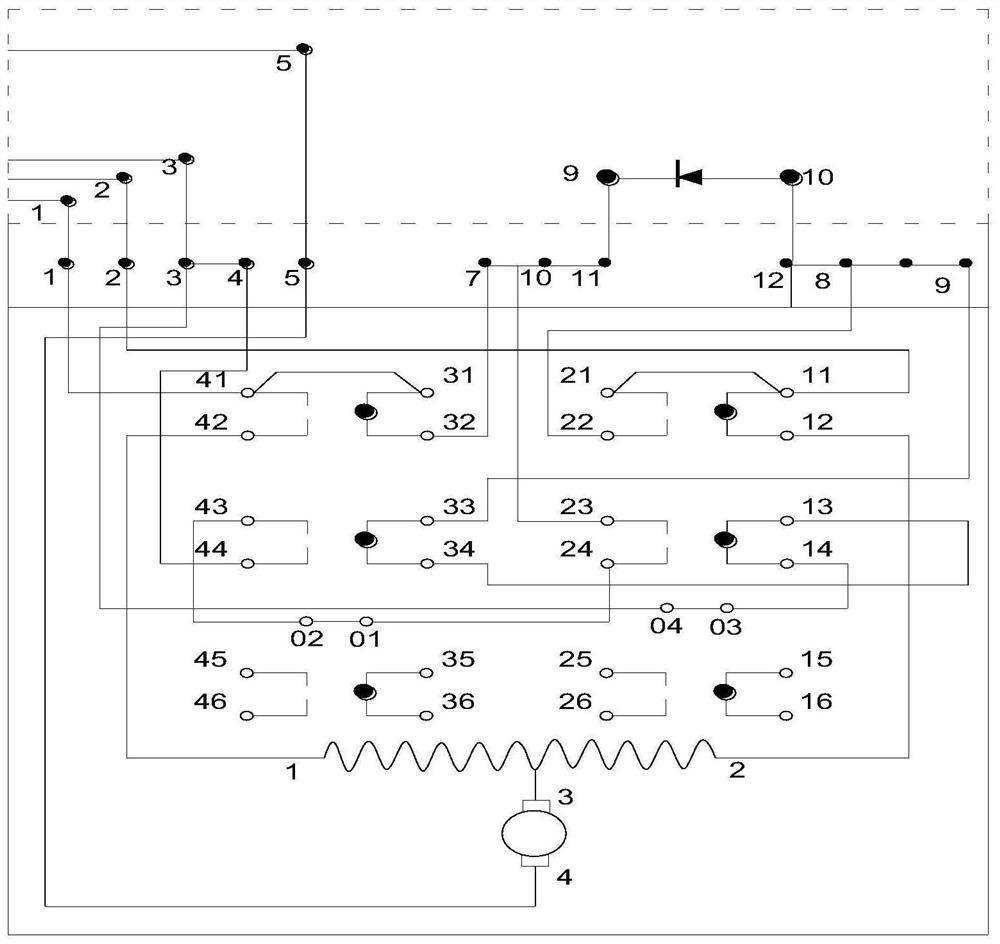

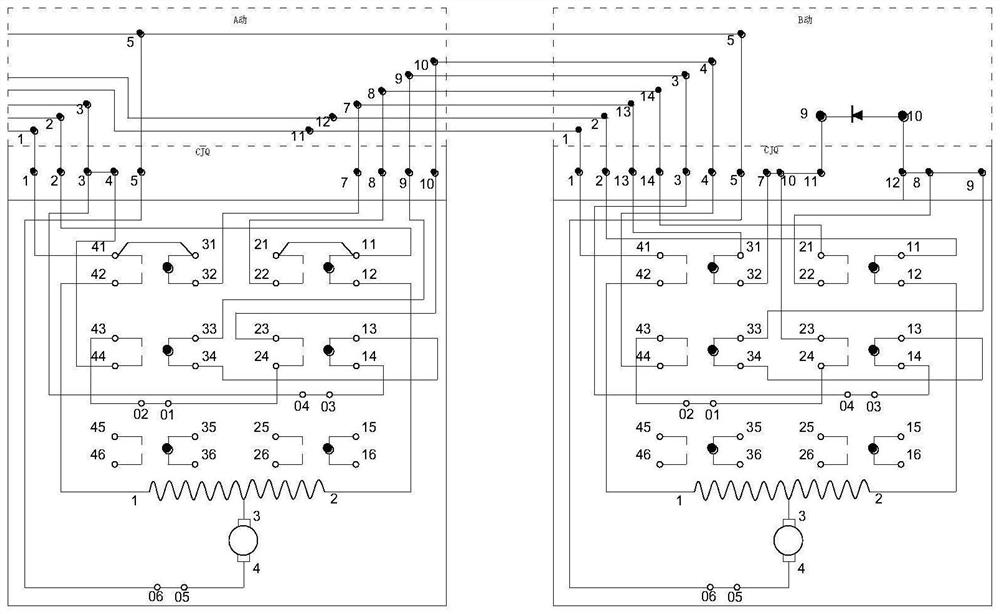

[0028] like figure 1 and figure 2 As shown, the present invention relates to a wiring method of a ZD6 switch machine for testing and testing, including: ZD6 switch machine testing cable box 15 and each terminal in the cable box 15, X1, X2, X3, X4 connecting wires and Switch machine pin box CJQ16, there are 13 wiring terminals in the switch machine pin box CJQ16, the 13 wiring terminals are respectively coded as: No. 1 terminal 1, No. 2 terminal 2, No. 3 terminal 3, No. 4 terminal 4. Terminal 5, Terminal 7, Terminal 8, Terminal 9, Terminal 9, Terminal 10, Terminal 11, Terminal 12, Terminal 13, Terminal 14, Terminal 14 ; X1, X2, X3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com