Coal mining machine electric control system replacement method and coal mining machine electric control system based on Internet

A technology of electronic control system and replacement method, applied in general control system, control/regulation system, computer control and other directions, can solve the problems of easy error, cumbersome process, increase time cost and economic cost, etc., achieve efficient switching and improve safety the effect of reducing time cost and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

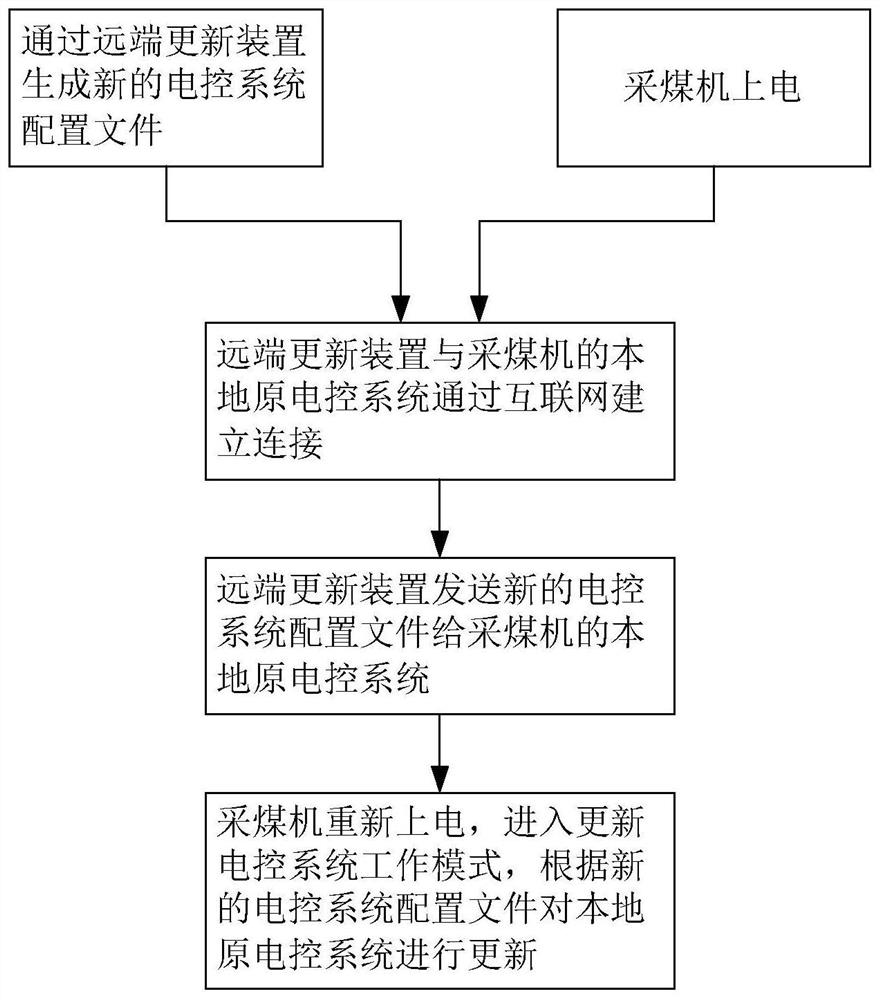

[0028] like figure 1 As shown, the present invention discloses a method for replacing a control system of a coal mining machine (which may be referred to as a method for replacing an electronic control system), comprising the following steps:

[0029] Step 1, generate a new electronic control system configuration file through the remote update device;

[0030] Step 2, the shearer is powered on;

[0031] Step 3, establishing a connection between the remote update device and the local original electric control system of the shearer through the Internet;

[0032] Step 4, the remote update device sends the new electric control system configuration file to the local original electric control system of the shearer;

[0033] Step 5, the shearer is powered on again, enters the working mode of updating the electric control system, and updates the local original electric control system according to the new electric control system configuration file.

[0034] Steps 1 and 2 are not req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com