Planetary gearbox health monitoring method based on modal reconstruction and bagging model

A planetary gearbox and model technology, applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc., can solve the problems of dynamic information noise interference of planetary gearboxes, higher requirements for generalization capabilities of diagnostic models, etc., to achieve Suppress random impact and strong noise interference, improve diagnostic efficiency and accuracy, and enhance the effect of fault characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

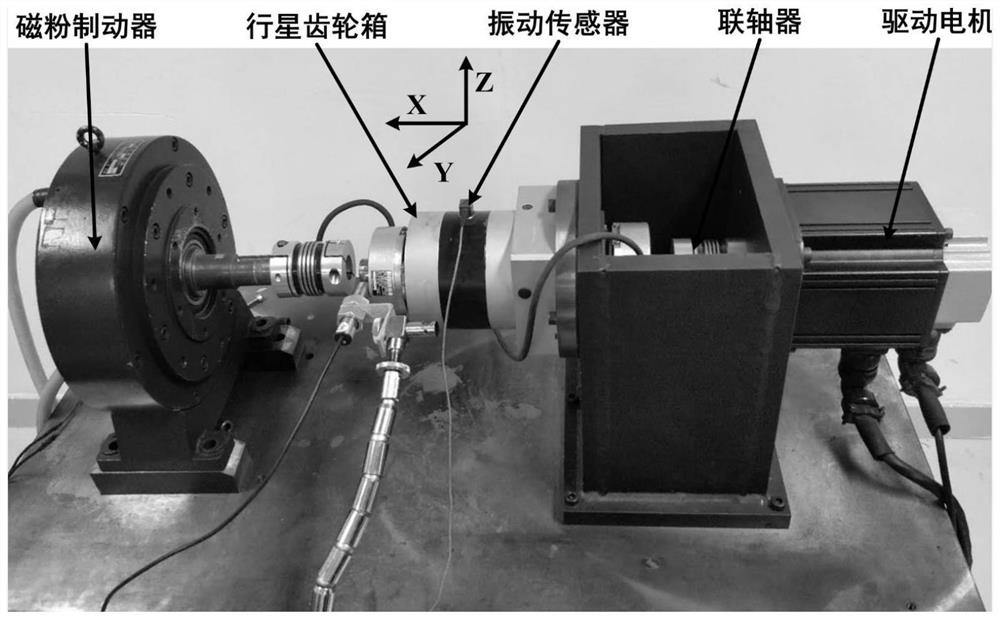

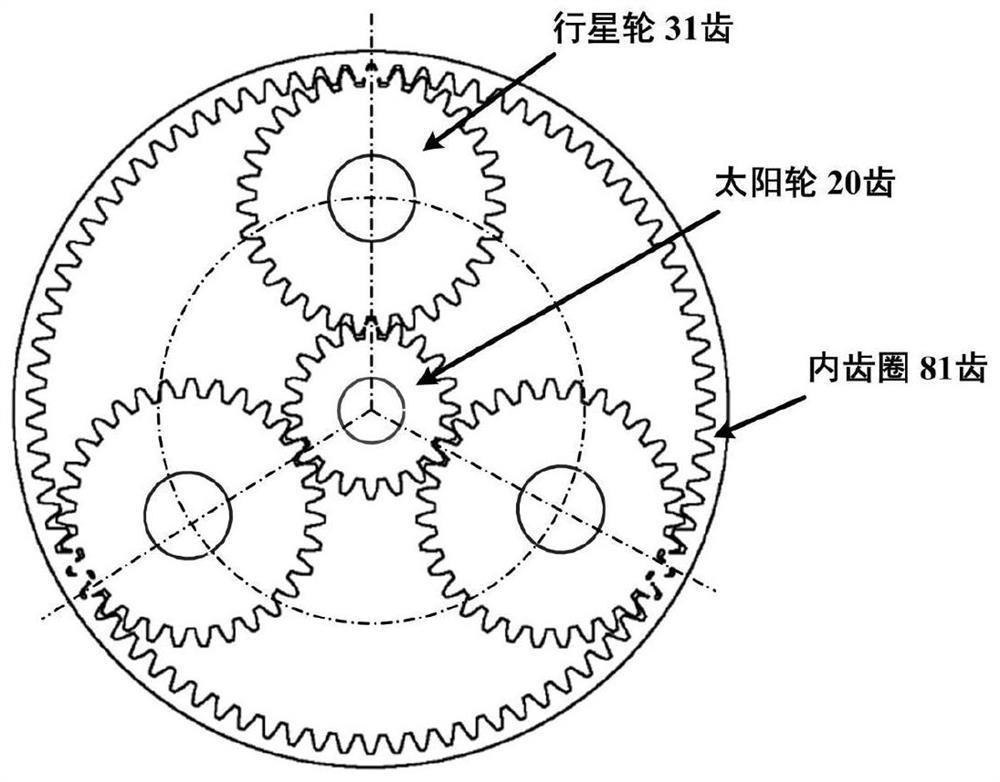

[0045] The following will take the planetary gear fault diagnosis experimental bench as an example. The experimental bench consists of a drive motor, a coupling, a planetary gearbox and a magnetic powder brake. The vibration sensor is installed on the planetary gearbox, such as figure 1 shown. The planetary gearbox is composed of a sun gear, an inner gear and three evenly distributed planetary gears, and the planet carrier is connected to the output shaft, such as figure 2 shown. In order to simulate the early failure of the gearbox, pitting corrosion and tooth surface wear are machined on the surface of the planetary gear, such as image 3 shown. The test bench is driven by a drive motor, which transmits the torque from the input shaft to the magnetic powder brake along the planetary gearbox, and the magnetic powder brake completes the load.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com