Compression-resistant fireproof cable

A technology of fireproof cable and fireproof layer, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of not being able to dissipate heat from cables, not having the function of auxiliary cable heat dissipation, etc., so as to avoid the spread of open fire and avoid direct contact wear and tear. , to avoid the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

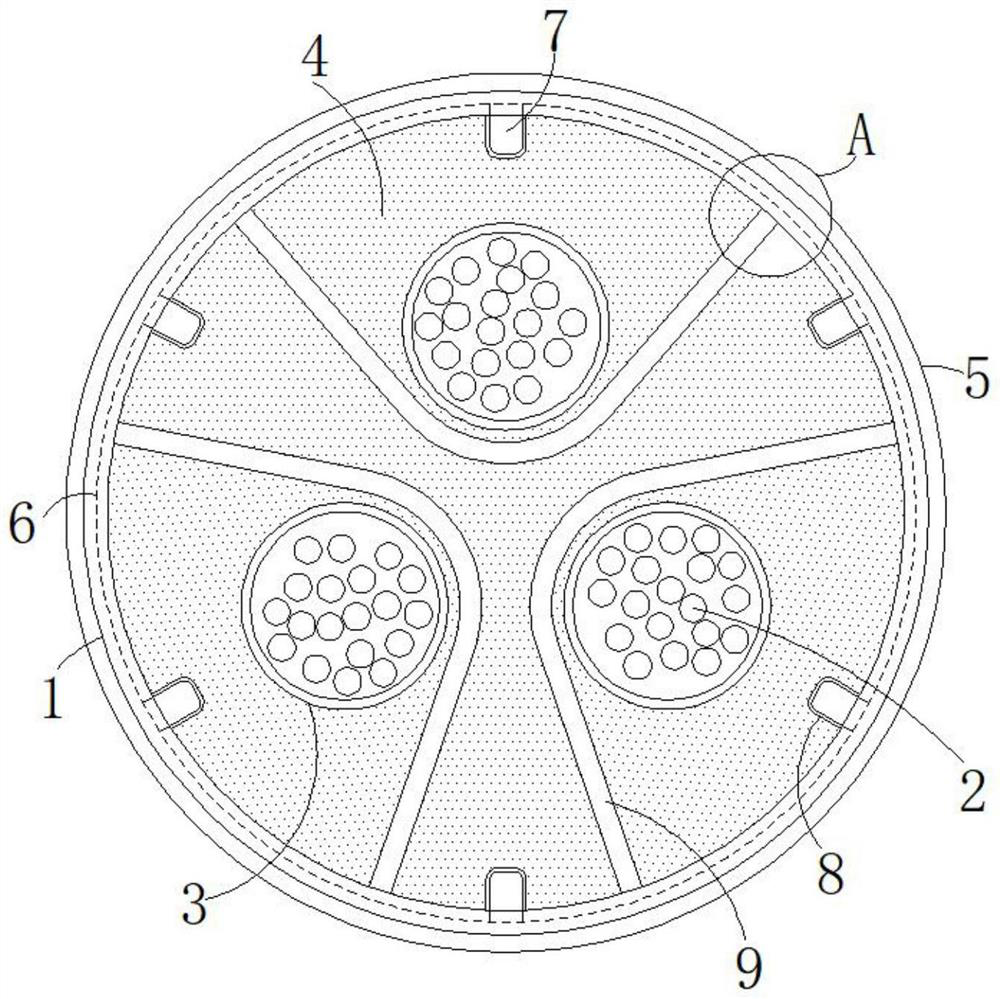

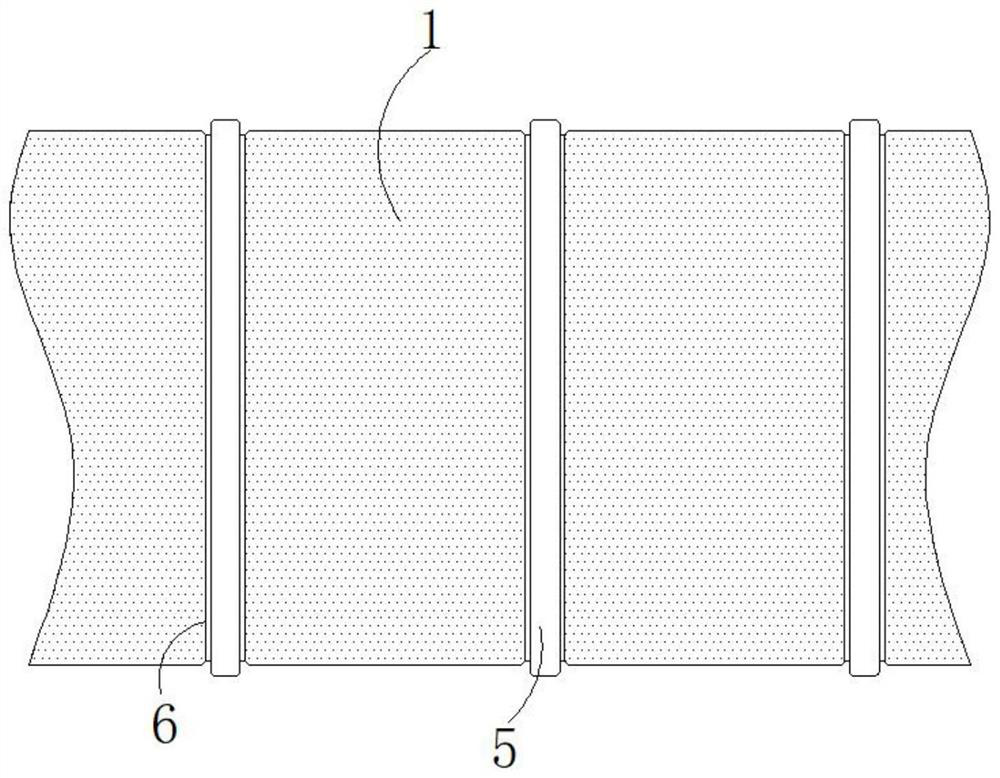

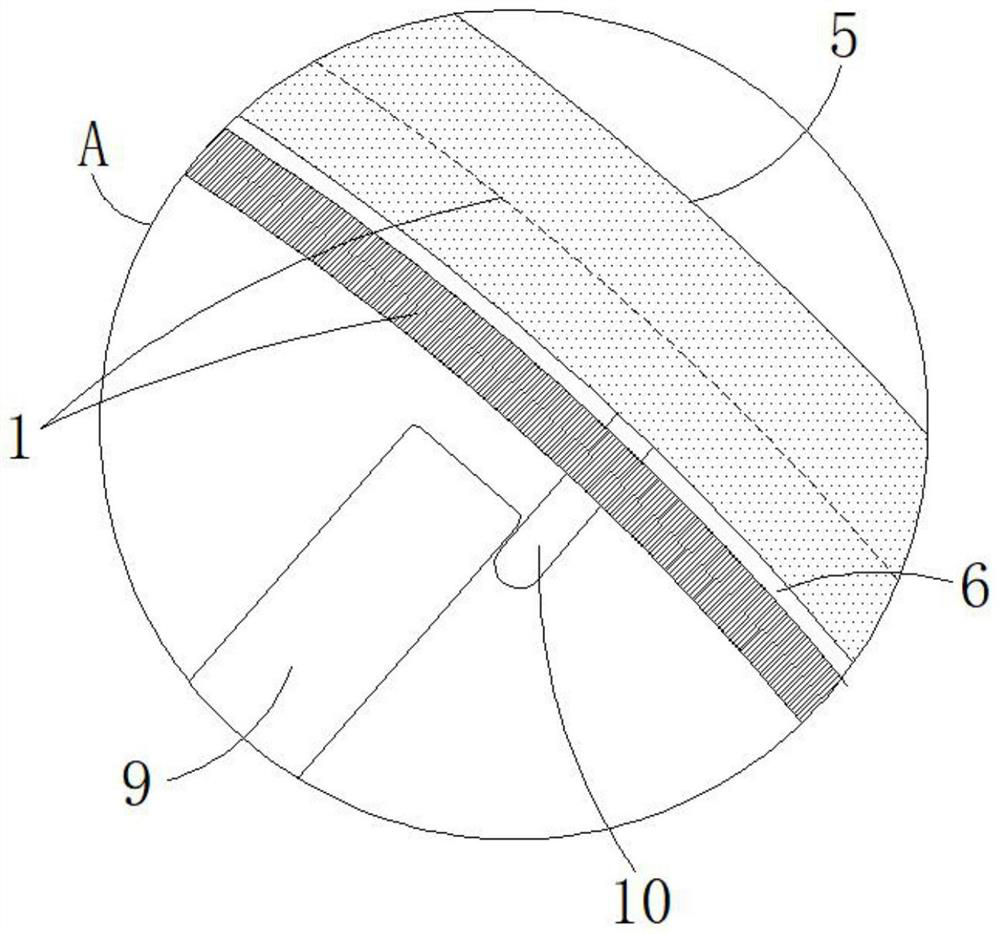

[0034] The fire cable includes a cable body 1 and a cable core 2 arranged inside the cable body 1. The outer wall of the cable core 2 is provided with a core protection layer 3, and the interior of the cable body 1 is filled with a flame retardant and fireproof layer 4. It also includes a protection sheet, the protection sheet fits into the outer wall of the cable body 1 through the positioning groove 6, and the outer surface of the protection sheet protrudes from the outer surface of the cable body 1, and the inner wall of the protection sheet is fixed with a splicing block 7, The splicing blocks 7 are equiangularly distributed with respect to the center of the cable body 1, and the splicing blocks 7 are matched with the splicing card slots 8. The splicing card slots 8 are opened in the cable body 1 and the flame retardant and fireproof layer 4, and the protective sheet is used for The cable body 1 is protected against compression. The anastomotic connection between the splici...

Embodiment 2

[0037] Different from the first embodiment, in order to avoid the phenomenon that the cable body 1 is twisted due to rolling during the placement process, in this embodiment, the protection sheet is the first protection patch 11, and the first protection patch is horizontally distributed. The axes of the sheet 11 and the cable body 1 are distributed parallel to each other, and the first protection patch 11 is distributed at an equal angle with respect to the center of the cable body 1, such as Figure 5-6 As shown, the first protection patch 11 is also a thermally conductive material, and on the basis of the protection and heat conduction effect of the protection ring 5 in the embodiment, the first protection patch 11 is also used to prevent the cable Body 1 rolls.

[0038] In this embodiment, the difference from Embodiment 1 is as follows. The heat dissipation device is a second metal strip 12 disposed inside the cable body 1. The end of the second metal strip 12 is also conn...

Embodiment 3

[0040] In the prior art, although there are some technologies in which a corresponding metal wire is arranged in the cable as the reinforcing structure of the cable, due to the aging of the cable and the deformation and damage of the cable caused by the external impact force, the cable core 2 runs under high load. The phenomenon of burning to produce open fire will occur, and at this time, these reinforcing structures not only cannot play a role in fire prevention, but also quickly conduct heat to other areas due to their thermal conductivity, resulting in faster burning of cables. Therefore, in this In the technical solution, in order to solve the above problem, the following solution is also provided. The protection sheet is the second protection patch 13. The second protection patch 13 is also equiangularly distributed with respect to the center of the cable body 1, and the second protection patch 13 is equiangularly distributed. The inner wall is fixed with a heat-conductin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com