A vibration damping device for a diaphragm coupling and a vibration damping method thereof

A diaphragm coupling and vibration damping device technology, which is applied in the direction of couplings, elastic couplings, non-rotational vibration suppression, etc., can solve the problem of no significant improvement in vibration reduction, increased diaphragm wear fatigue, and failure to achieve vibration reduction Effect and other issues, to achieve good vibration damping effect, avoid direct contact wear, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in more detail below in conjunction with accompanying drawing example, further clarifies the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand the present invention Modifications of various equivalent forms of the invention all fall within the scope defined by the appended claims of the present application.

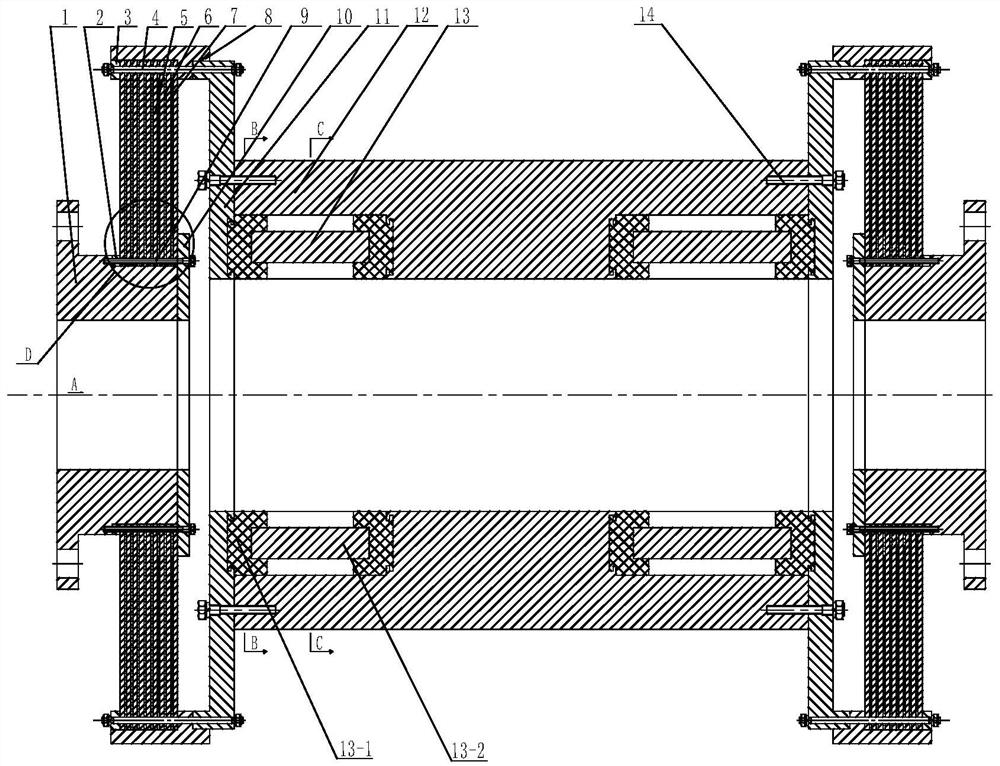

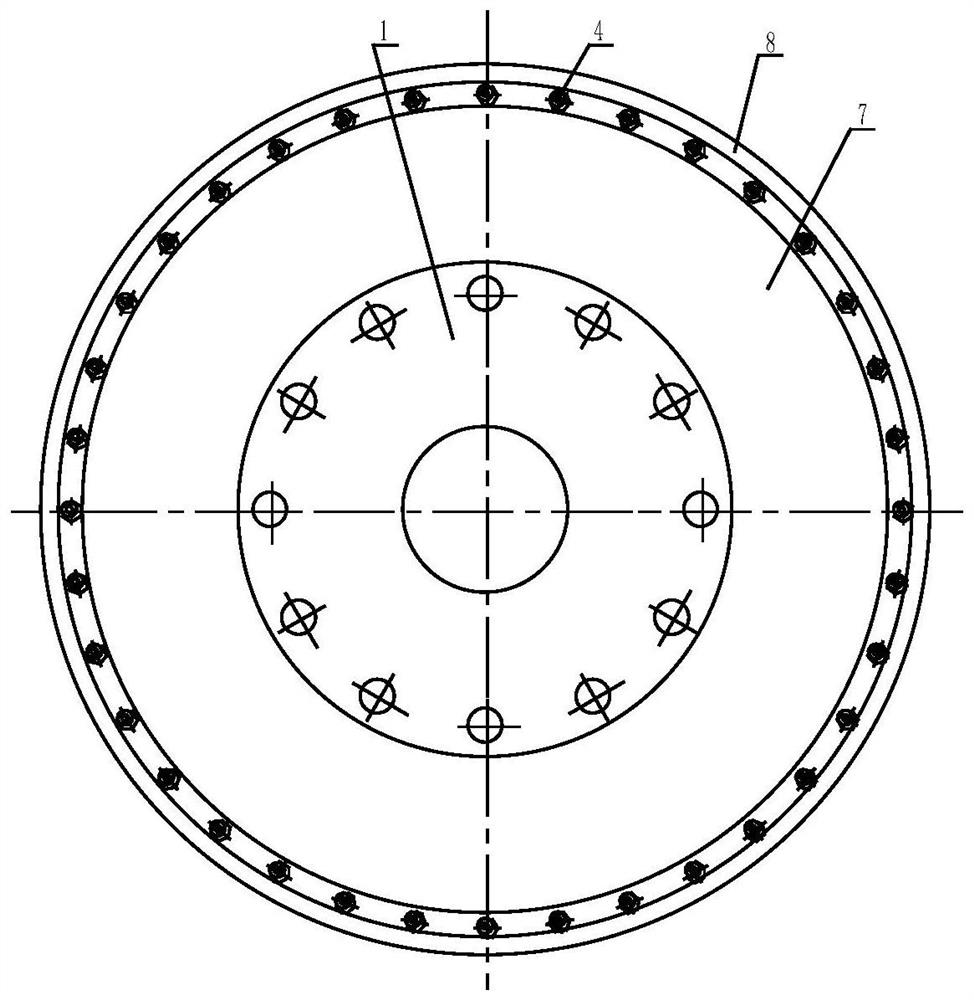

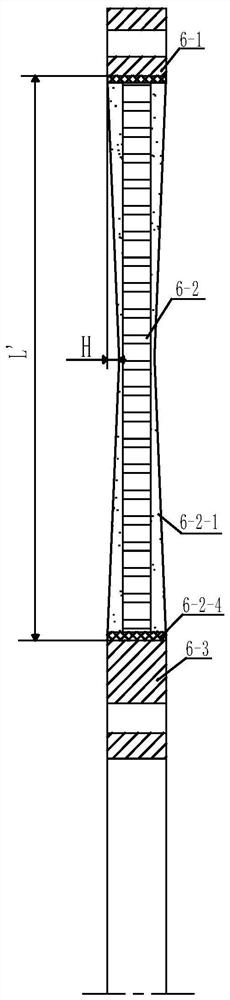

[0039] Such as Figure 1 to Figure 7 As shown, it is a vibration damping device for a diaphragm coupling of the present invention, including an intermediate shaft 12, which is a sleeve-shaped structure with a large diameter at both ends and a small diameter in the middle, and the two ends of the intermediate shaft 12 The intermediate flange 11 and the outer flange 8 are respectively successively connected, and the intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com