Lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as difficulty in rehydration and hidden dangers, avoid increasing the decay rate, improve cycle life, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

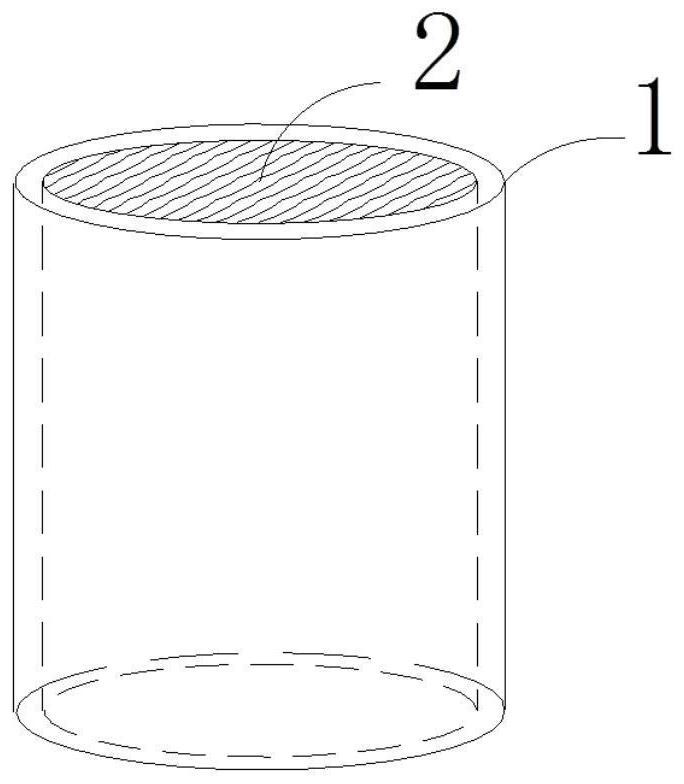

[0049] In the gap between the winding core 2 and the inner wall of the casing 1, the storage liquid 3 is not filled, such as figure 1 shown. The cell failed the UN38.3 vibration test, and the capacity retention rate was only 80% after 600 cycles at 55°C.

Embodiment 2

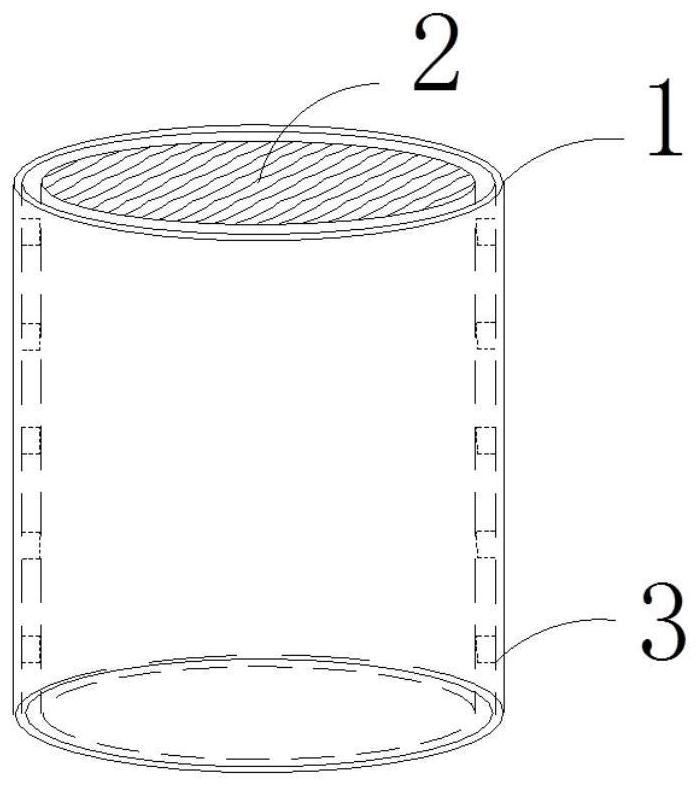

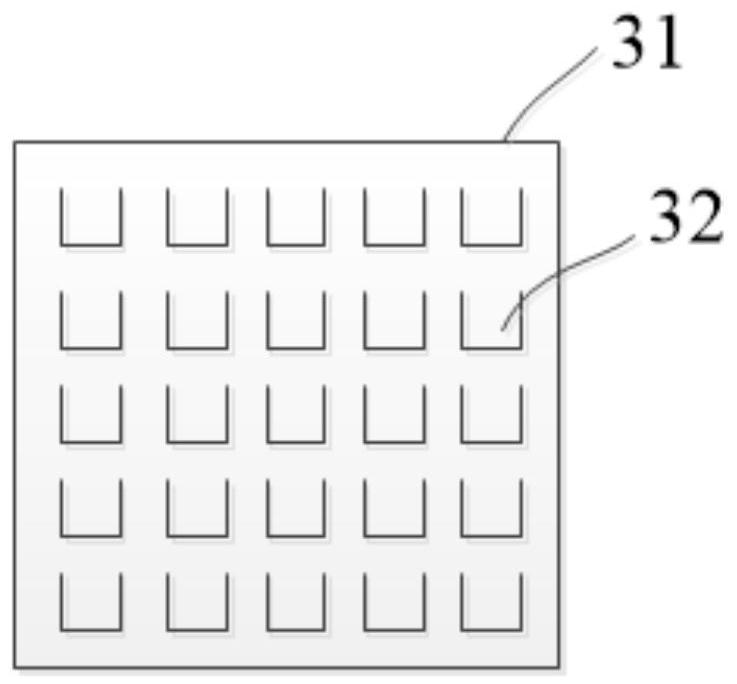

[0051] The gap between the winding core 2 and the inner wall of the casing 1 is filled with a liquid storage 3 with a plurality of rectangular storage bags 32. The unfolded state of the liquid storage 3 is as follows: image 3 shown. The cell can pass the UN38.3 vibration test, and the capacity retention rate is 90.5% after 600 cycles at 55°C.

Embodiment 3

[0053] The gap between the winding core 2 and the inner wall of the casing 1 is filled with liquid storage 3 with a plurality of triangular storage bags 32 in a circle. The unfolded state of the liquid storage 3 is as follows: Image 6 shown. The cell can pass the UN38.3 vibration test, and the capacity retention rate is 89.4% after 600 cycles at 55°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com